One of the main concerns of this study is to translate environmental practices into strategic actions. This paper aims to analyze how a representative segment of the Brazilian agribusiness, the Mato Grosso do Sul sugarcane industry, is dealing with environmental management at the strategic level. Three data sources were used, which are: semi-structured interviews, questionnaire, and a review of documents and reports. The analysis of interview and documents was carried out through content analysis. Data triangulation was used to combine the results of all three research tools. The methodology is the application of a sustainability assessment model. By analyzing the Brazilian sugarcane main practices, this industry still heavily emphasizes corrective actions focused both on monitoring and on controlling. However, data suggest an increasing effort towards preventive behavior and towards understanding environmental sustainability as a business strategy. This study promotes the knowledge of the indicators to measure the sustainable performance of the sugarcane energy sector. The relevance of the research is amplified considering that Brazil is one of the main countries producing sugarcane and ethanol; the socio-environmental impact of this sector; and the challenges for the measurement of sustainability in agribusiness.

Brazil remains the world's largest sugar producer and exporter according to the latest reports from the Organization for Economic Cooperation and Development (OECD) and United Nations Food and Agriculture Organization (FAO) (OECD/FAO, 2015). In 2013, Brazil accounted for 38.6% of the world’s ethanol exports (Brasil, 2014). In the 2013/2014 harvest, Brazil produced 25.57 million m³ of ethanol using 327 million tons of sugarcane, which is equivalent to 54.8% of the total national production.

According to Scarpare et al. (2016), Southern Central region concentrates about 85% of total sugarcane production in Brazil, which are: Parana (PR), São Paulo (SP), Rio de Janeiro (RJ), Minas Gerais (MG), Espírito Santo (ES), Mato Grosso do Sul (MS), Goiás (GO), and Mato Grosso (MT) States. The state of Mato Grosso do Sul is the fourth largest producer by volume in Brazil. In the 2013/2014 harvest, the state produced 2,474,433 m³ of ethanol; approximately 9.5% of the national total volume, as shown by the Association of Bioenergy Producers of Mato Grosso do Sul (Biosul) (2015). As noted by the Brazilian Sugarcane Industry Association (UNICA, 2014), in the state of Mato Grosso do Sul, the sugarcane energy industry is continuously expanding; in just the last harvest (2013/2014), two new sugarcane production units began operations in the state.

Considering the final product, the sugarcane industry is very important because of the production of fuel from sugarcane biomass (Carvalho, 2012; Scarpare et al., 2016). As sustainability strategies, Palma-Rojas et al. (2017) argue that the promotion of production and use of biofuels are examples of strategies to reduce greenhouse gas (GHG) emissions and environmental impacts. In this respect according to Cortez et al. (2003), “the use of ethanol as a gasoline substitute in cars and light trucks is possibly one of the most attractive and feasible alternatives to deal with global warming”. However, from the point of view of operations, the sugarcane industry has been facing challenges such as deforestation, pollution, misuse of natural resources, negative health impacts on employees and the local community, and social inequality (Kasurinen et al., 2017; Turetta et al., 2017).

When considering the social and environmental impacts of production activities, Porter (1996) states that there is a false dichotomy based on a narrow view of the sources of wealth and a static view of competition. Luning (2012) says that in recent years, companies no longer worry only about the safety and well-being of their own employees but have also taken responsibility for caring about the environment in which they are operating. Some companies have shown their commitment to sustainability with projects related to community development and environmental protection as implemented by international organizations (Slack, 2012).

The relationship between the academic importance given to matters related to environmental issues is still inversely related to the number of studies that show how sustainability occurs in some sectors, including the sugarcane energy industry (Florin et al., 2014). When addressing the sugarcane energy industry from a sustainability perspective, authors such as Cançado et al. (2006) and Duarte et al. (2013) argue that some of these industrial practices compromise sustainable development. Bergquist et al. (2012), Duarte et al. (2013) and Smeets et al. (2008) note a number of environmental and social problems caused by the expansion of sugarcane monocultures, such as soil degradation, land concentration, deforestation, soil and water pollution, water course bed sedimentation and erosion, poisoning of humans and animals, and decreasing biodiversity.

Turetta et al. (2017) argue that the technical subside employed by policy makers to direct sugarcane production expansion (Sugarcane Agroecology Zoning) is considered limited. Regarding this issue, the authors propose a framework to evaluate biofuel sustainability to support public policies.

Thus, researchers such as Machado and Silva (2010), Scarpare et al. (2016), Turetta et al. (2017) and Palma-Rojas et al. (2017) have expressed the need for additional comprehensive studies that help clarify the process of environmental management in the sugarcane energy industry. In such a way that Brazilian companies may compete on equal terms in the global market, training in eco-efficiency terms as well as an understanding of how organizations are working to achieve sustainability is necessary (Brasil, 2004; Schaffel and La Rovere, 2010). In responding to environmental challenges, companies have expanded their search for a balance in their business activities among the environmental, social and economic aspects (Gimenez et al., 2012).

Taking this into consideration, a research question arises: How does one characterize the environmental aspects of the sustainable performance of the sugarcane energy industry in Mato Grosso do Sul (Brazil)? The aim of this study is to analyse which environmental management strategies companies in the sugarcane energy sector in the State of Mato Grosso do Sul are applying.

This research is qualitative, exploratory and descriptive. The methodology included multiple case studies (Creswell, 2013; Yin, 2013). Applying replication logic, this empirical research was conducted by analysing three sugarcane energy plants operating in the State of Mato Grosso do Sul (Yin, 2013). Biosul has assisted with the selection of cases and the number of plants chosen was based on accessibility, existing resources and time availability (Rowley, 2002).

Three data sources were used in the study, which are: semi-structured interviews, questionnaires, and a review of companies’ documents and reports. The data was collected in 2016, during the period from January to May. Data triangulation was used to combine the results of all three research tools (Yin, 2013).

The questionnaire was structured considering environmental aspects of the plants and the performance of companies in terms of sustainability. The questionnaires were answered by the staff responsible for the plants’ environmental/sustainability matters. The interviews were carried out in the sequence of the questionnaire. They were based in a semi-structured script to obtain a more qualitative impression on the points covered in the questionnaire. The interviews sought evidence of the level of environmental sustainability in connection with business sustainability, strategy and environmental management issues while also considering the theoretical premises of studies in these areas (Kleindorfer, Singhal, & Wassenhove, 2005; Krajnc & GlaviÄ, 2005; Parnell, 2008).

The analysis of interview was carried out through content analysis (Bardin, 2011; Mozzato & Grzybovski, 2011). Initially, the interviews were transcribed and then the identified evidences were classified according to the parameters presented in Table 7. In the sequence, the intra- and inter-case analysis was performed, comparing the empirical results with what is affirmed by the theory (Flick, 2009; Gil, 2002). The public information of the plants (documents and reports) were analyzed to complement and confirm the answers given by the questionnaires and the interviews, relating them to the theory (Flick, 2009; Gil, 2002).

The questions in the questionnaire were adapted from the Callado and Fensterseifer's model (2011). The reasons for choosing Callado and Fensterseifer's model (2011) are that (1) the weights attributed to each indicator have already been applied in other studies (Andrade and Câmara, 2012; Souza and Gómez, 2014) and (2) the indicators established in the model allow for the understanding and replication of the calculation as well as the measurement of the results. This model allows for the analysis of companies from different industries and their perspectives, thus enabling replication of the research.

For each indicator of environmental sustainability considered in the model, three performance levels were proposed, and values were assigned according to the performance level presented by the company being analysed, namely, 1 = Lower Performance; 2 = Intermediate Performance; and 3 = Superior Performance. Callado and Fensterseifer's model (2011) uses weights defined by experts for the performance indicator i (wi), the level of performance given by indicator i (pi), and the number of indicators considered (n) to calculate the score corresponding to each performance level of each indicator. The formula for calculating the scores is Score:

Based on the formula, a possible minimum score (50.786), average score (101.572) and maximum score (152.358) were established. When the analysed company showed a performance score equal to or higher than the average score, it was interpreted as having satisfactory performance; when the analysed company showed a performance value lower than the average score, this was interpreted as unsatisfactory performance.

Before being released to the plants, a pre-test of the data collection instrument was developed with the Biosul technical advisor in order to consolidate its validity for this sector, given that the instrument is adapted from an already validated model. The Biosul technical advisor was interviewed and assumed the role of key informant (Malhotra, 2008); the advisor provided information and an evaluation of the study in order to validate and supplement the information obtained by the research conducted at the plants.

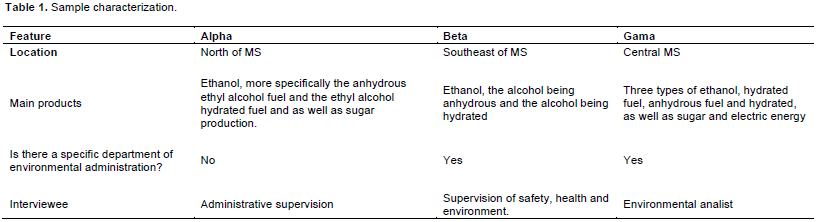

With the information obtained from multiple sources and the logic of replication, multiple cases were compared in order to identify the existence of any divergent and convergent patterns between them. The identity of the plants was preserved, and they were labelled Alpha, Beta and Gama Plants. The firms are characterized in Table 1.

Business sustainability as a strategic element

The definition of the term ‘sustainable development’ is ‘development that seeks to meet the needs of the present generation without jeopardizing the ability of future generations to meet their own needs’ (World Commission on Environment and Development, 1987). Business sustainability, on the other hand, is a set of more objective actions that can achieve such development. Sustainable development is understood to comprise countless types of sustainability, including business sustainability. According to Ahi and Searcy (2013), ‘in a broad sense, business sustainability means the resiliency of organizations over time, where they are closely connected to healthy environmental, economic and social systems to become better positioned to respond to internal and external shocks’. International markets have demanded an increase in the ratio between trade and sustainable development; this ratio grows as a trend in response to global pressure, which should be satisfied by governments and companies (Griggs et al., 2013). The Brazilian agribusiness export sector, specifically the sugarcane energy industry, occupies a relevant position on the global scene. According to OECD/FAO (2015) data, Brazil ranks first in the world for sugar production and exports and ranks second in ethanol production; Brazil has the needed technology, the means of distribution, and the capacity to expand its sugarcane planting area without harming the production of other food crops.

Concurrently, increasing pressure from stakeholders has resulted in the growing importance of sustainability; stakeholders oppose the increasing environmental degradation caused by companies worldwide (Turetta et al., 2017; Wolf, 2014). Dyllick and Hockerts (2002) argue that a sustainable company meets both the direct and indirect needs of its current stakeholders and is also socially and environmentally responsible (Kasurinen et al., 2017).

Society perceives that many social and environmental problems are derived from business activities and, furthermore, that the ongoing advance of globalization exacerbates these problems; this attention makes companies aware of the importance of acting in a sustainable manner. On that basis, companies are driven to act both reactively and pro-actively to achieve sustainability (Kasurinen et al., 2017). This is because it is part of the requirements of their internal and external customers and is crucial for companies attempting to operate mainly as exporters.

Based on this background, the need for business sustainability and the integration of sustainability dimensions into business management emerged. Several management models were created in order to develop this integration. Among them, Pawłowski (2008) proposes seven sustainability dimensions, including environmental, social, moral, economic, legal, technical and political. Sachs (1993) proposes five dimensions: social, economic, ecological, spatial and cultural. Oliveira (2002) uses four dimensions: social, environmental, economic and cultural. However, the best-known dimensions were those proposed by John Elkington, which include the environmental, social and economic perspectives. The latter model is called the triple bottom line (triple line of net income) and aims at integrating the social, environmental and economic aspects of the company (Elkington, 1999), thus summarizing the other approaches.

Companies need to be connected to the different aspects of their environment. Managers who wish to make efficient and effective decisions about their business should hence know the impacts caused by their organization’s products, services and processes. These impacts can be seen, for example, in the social dimension as a failure to adopt human resource policies that support the dedication of employees to their families (Collins et al., 2007; Kasurinen et al., 2017) in the environmental dimension, as seen in the unsustainable use of natural resources (Dyllick and Hockerts, 2002; Turetta et al., 2017); and in the economic dimension, as seen in the non-implementation of environmental management systems (Phan and Baird, 2015; Rankin et al., 2011).

According to Sharma and Henriques (2005), who researched the forestry industry in Canada, the main sustainability practices are pollution control, eco-efficiency, recirculation of inputs and outputs, and eco-design. Other authors such as Chiou et al. (2008), Govindan et al. (2015) and Grisi et al. (2010) note some practices, such as green material selection, waste management, internalization of the cost of pollution effects, and analysis of the carbon footprint. In addition, some authors highlight the importance of using certificates such as ISO 14000, avoiding the use of ozone layer-harming substances, and using recyclable content (Govindan et al., 2015; Grisi et al., 2010; Handfield et al., 2002; Lee et al., 2009).

Nidumolu et al., (2009) made a statement that ‘in the future, only companies that make sustainability as a goal will achieve competitive advantage’ is the basis of the motivations for including sustainability in a company’s strategy. This business strategy is a key element driving companies towards sustainability (Hoogma et al., 2005; Klassen and Mclaughlin, 1996). Parnell (2008) defines sustainable strategic management as the strategies and processes related to continued superior performance in the environmental, social and market aspects and in the market.

Among the advantages of maintaining a strategy for sustainability are the added value to the company image, which is reflected in the influence of customers’ loyal behaviour, and increases in income and the personal satisfaction of employees (Severo et al., 2015; Vries et al., 2015). In addition, a benefit of integrating sustainability into the business strategy is the attainment of environmentally conscious consumers, which makes the use of an environmental marketing strategy possible (Ginsberg and Bloom, 2004; Leary et al., 2014).

The range of new markets derived from exports to countries with stricter environmental laws, the increased value of shares of companies in the capital markets, and the economic benefits from the disclosure of environmentally friendly actions by companies (Miles and Covin, 2000). These are motivators that directly affect company profitability and should catch managers’ attention.

At the operational level, organizations can achieve sustainable value by integrating sustainability into the overall business strategy. Once technologies for environmental protection are no longer seen as optional but are rather considered an inevitable path, operational strategies will include their development and use (Alberti et al., 2000; Carvalho, 2012).

Therefore, in the current scenario of constant change and resource scarcity awareness, managers are challenged to position their organizations so that they generate sustainable value for stakeholders by aligning their operational strategies with sustainable management practices (Epstein and Roy, 1998; Kasurinen et al., 2017). According to Hart and Milstein (2004), this alignment will help organizations to minimize losses from operations while redirecting their skill portfolios towards more sustainable technologies and capabilities. In addition, organizations should engage in a broad interaction and dialogue with external stakeholders to outline how they could develop economically attractive solutions to future social and environmental problems.

According to the model Callado and Fensterseifer’s (2011) model, the sustainability criteria have to be measurable. First, the author selected sustainable indicators based on the literature and submitted them to specialists. As a result, they gathered 43 indicators in total: 16 environmental, 14 economic and 13 social. Next, the authors proposed the partial sustainability indicators (EPS) composed of economic, social, and environmental indicators (EPSA = environmental, EPSE = economic and EPS S = social). The importance of each indicator in the model was validated by specialists. At the end, the model provides a sustainable aggregate index, a score of business sustainability (ESE), dado por: ESE = EPS A + EPSE + EPSS. In addition, the authors elaborated the Grid of Business Sustainability (GSE), which makes it possible to evaluate and classify companies from different sectors.

For the elaboration of the questionnaire, the authors considered twelve variables presented in model of Callado and Fensterseifer (2011). Based on the model, the number of variables considered in the study was expanded. This adaptation was necessary in order to avoid the overlap of the indicators and to ensure the consideration of variables more closely related to the reality of the sector analysed. The details of the environmental dimension are shown in Table 2 the details of the economic dimension are shown in Table 3 and the details of the social dimension are shown in Table 4.

The sugarcane energy sector and environmental management

The OECD/FAO (2015) state that ‘global sugarcane production will increase by 21% over the period and the share of global sugarcane production processed for ethanol is set to expand from 20% in the base period (2012-2014) to 25% by 2024’. The data show that nearly 60% of the additional sugarcane production will come from Brazil, which is the main sugarcane producer (OECD/FAO, 2015).

Brazilian ethanol made from sugarcane is a better option for the production of ethanol than either corn or lignocellulose. Furthermore, the country has the technology, the means of distribution and the possibility of expanding the planting area without compromising the production of other food crops (Brasil, 2008). The Brazilian state of Mato Grosso do Sul (Figure 1) has 22 plants in operation. Fifteen of these are owned by business groups, which may increase the likelihood of a specific department for sustainability. According to the 2013/2014 crop data, the state represents 6.35% of the Brazilian sugarcane production and 8.1% of the total production of ethanol in the country (UNICA, 2014). The state ranks fourth for sugar exports and accounts for 4.16% of the Brazilian total 2013/2014 harvest (UNICA, 2015).

Regarding sustainability in the sugarcane energy industry in Mato Grosso do Sul, eight plants have the Senai Eco-Efficiency Program Green Seal, reflecting that proper environmental practices are in place. The Brazilian sugarcane energy sector, which targets local and export markets, should meet the international market standards that require mandatory proof of the sector’s sustainable performance as an entry barrier. Such proof is made available by means of certifications. The following are the certifications highlighted by Scarlat and Dallemand (2011):

(1) Round Table on Sustainable Biofuels (RSB): aims at developing international sustainability standards for biofuels;

(2) Renewable Fuel Standard (RFS2): a US government programme administered by the Environmental Protection Agency (EPA) to certify sustainable practices of the plant based on global standards;

(3) International Organization for Standardization (ISO 14001): the main management system standard that specifies the requirements for formulating and maintaining an environmental management system, helping to manage its environmental aspects, reducing impacts and ensuring legal compliance;

(4) Better Sugarcane Initiative (Bonsucro): seeks to incorporate a set of principles, criteria, indicators and verifiers used to certify sugarcane producers’ compliance with these principles and to guide companies in the sugarcane value chain for the purchase of raw material/sustainable supplies and the financial sector to make more sustainable investments.

Strategically, a company’s strong environmental performance can be used to enhance its reputation, and the reverse is also true. With the current global focus on reducing pollution and gas emissions and the protection of the environment, a company disregarding these issues may find it difficult to remain in the market. Managers can choose to act reactively or pro-actively regarding environmental issues; however, according to a study by the Intergovernmental Panel on Climate Change (IPCC), it is necessary to prove that pro-activity is more beneficial for both financial and global quality of life reasons (Brasil, 2005).

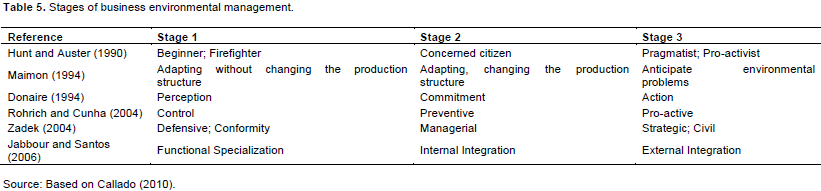

To understand where businesses are in the evolutionary process towards environmentally friendly management, some authors have separated the process into distinct stages. These authors have adopted different nomenclatures but in general have condensed them into three steps, as shown in Table 5. These steps range from the so-called reactive level, where the focus is pollution control resulting from pressures from stakeholders and legal requirements; pollution prevention, in which the efficient use of inputs prevents the generation of pollution; and the strategic stage at which the environmental dimension is essential for achieving competitive advantage.

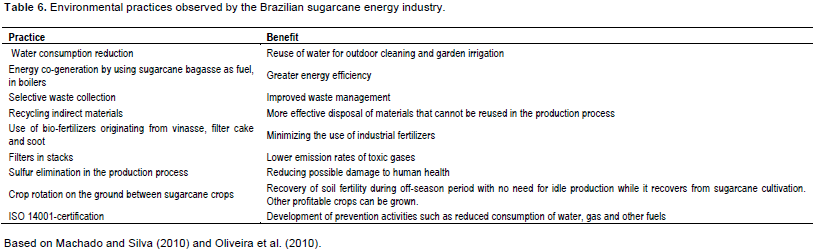

To move forward in the environmental management evolutionary process and to change its negative image regarding its production operations, the sugarcane energy industry must introduce environmental practices that improve the environment surrounding the plant and consequently reduce or even eliminate its negative impacts. Table 6 shows some of the environmental practices adopted by Brazilian plants.

In addition to the practices outlined above, the improved use of by-products and the development of new goods from sugarcane are seen as positive prospects for the sector (Carreira and Franco, 2012; Renouf et al., 2013). Thus, the use of new and better technologies that provide greater production efficiency for the sector is highlighted. This scenario includes the diversification of sugar production; new ways of organizing and managing production; the marketing of by-products; and replacement of the burning process with mechanized cutting and planting of sugarcane (Prasara-A and Gheewala, 2015).

This topic presents the results of a data cross-analysis that attempts to determine the similarities and differences among the analysed plants given the different characteristics among them, such as an active and specific sustainability department sustainability department, diversification of production and belonging to an economic group.

The environment as a strategic element

Public pressure for improved environmental performance remains constant, as stated by Kleindorfer et al. (2005); yet, the economic return for such positioning is not so clear, especially with regard to the sugarcane energy industry sector. To stimulate plants to include the environmental variable in their strategies, it is necessary to have goals beyond the mere intention of greater financial return. Among these objectives, environmental management provides the possibility of reducing losses in the production process, either by better control and use of inputs or by the use of by-products that directly or indirectly add economic value.

The alpha plant states that ‘environmental protection is no longer an environmentalists’ issue only, but rather an item that has become of great importance in business strategies [...] adopting sustainable environmental practices that can increase company competitiveness in the national and in the international scenarios.’ From this point of view, the plant’s administrative supervisor emphasizes that when faced with this scenario, the plant could not avoid acting. Therefore, aiming to reduce its impact, it develops projects and environment-focused activities.

Regarding legal compliance, Beta Plant reports that it has all pertaining licenses and certifications and has accomplished all the actions required by government environmental control and monitoring agencies, which form the basis of qualification for sugarcane energy activity. Proper environmental management helps plants to conform to standards and legislation, which are very complex due to the nature of their business. As recommended by Porter (1996), stricter standards regarding the environment generate productive innovation, making products and processes more sustainable and less costly. To abide by these laws, plants will have the chance to improve the quality of their products, and by doing so, their image will improve as well.

The Beta and Gama Plants have a specific department for the management of sustainability. At Beta, the responsible person for this area is the safety, health and environment supervisor, while at Gama, the environmental analyst is held accountable. Without a specific department in charge, the Alpha Plant confirms the reports of the two other analysed plants by stating that the environmental management issue is handled by different departments within the plant at different levels of collaboration. In this regard, for the more external activities (e.g., sugarcane production workers), there is less collaboration from employees, and it is more difficult to achieve.

Concerning references to the environmental variable in the strategic planning of these plants, only the Gama Plant was clearly observed to have the term sustainability as part of both its strategy and future vision. This is because it is the only plant that belongs to a business group, with four other plants, holding a Bonsucro certification.

Bonsucro’s mission is ‘to promote sustainability in the sugarcane energy industry by means of a metric standard and a certification system, and supporting the continuous improvement of the practices of its members’ (Bonsucro, 2013), which shows the group’s willingness to achieve sustainable performance.

In accordance with the Gama Plant’s strategic environmental vision, the business group responsible for it states that all the group’s plants have Renewable Fuel Standard (RFS2) certification. In addition, the business group to which the Gama Plant belongs issues annual reports based on the sustainability guidelines of the Global Reporting Initiative (GRI). Regarding certifications accrediting the environmental management of the plants, only the Beta Plant reported having ISO 14001, a certification that, according to Gavronski et al. (2008), presents internal benefits, such as financial and productivity gains, and external ones, such as a better relationship with stakeholders and greater competitiveness.

Environmental practices adopted

The analysed plants had intermediate or high results in most cases, based on the theoretical background, since they all have similar practices. The peculiarities of the individual performance of the analysed plants in relation to environmental parameters are listed as follows:

(1) Fossil fuel consumption: two of the analysed plants obtained intermediate scores on fossil fuel consumption once their consumption remained constant. The Alpha Plant showed a decrease in consumption; however, this resulted from the decrease in the number of plant trucks. The Beta Plant reported an increase in consumption, which was justified by the acquisition of agricultural equipment. The Gama Plant was an exception, as it reduced the consumption of fossil fuels by managing indicators;

(2) Composition of the energy matrix: all the analysed plants have superior performance in this area, therefore, their matrices are mostly composed of renewable energy sources, and bagasse is the main component of their energy matrix;

(3) Impacts on soil: all the analysed plants obtained intermediate performance scores in the soil quality indicator. They all declared that they were having an impact on soil, in particular through erosion, but also confirmed the existence of actions intended to reduce such impacts. Monitoring and sound practices of soil management are the actions developed by the Beta Plant to reduce impacts, while the two other plants reported having practices in place but did not submit examples or details about them; (4) Impacts on surface water: only the Alpha Plant confirmed the existence of impacts on surface water; however, the plant also mentioned that it preserves riparian forests in order to minimize this impact. The Beta and Gama Plants reported no impacts on surface water; monitoring and control to prevent possible contamination are the main practices for such performance;

(5) Water reuse: the three analysed plants mentioned that their water reuse processes are fully developed, largely through the application of closed-loop system technology. In addition, the Gama Plant reported the use of an ‘Estação de Tratamento de Águas de Lavagem dos Gases’ (ETALG) [Gas Washing Water Treatment Plant];

(6) Reduction in emissions of solid, liquid and gaseous wastes: the Alpha and Beta Plants stated that they have a fully developed process in place to reduce the emission of solid, liquid and gaseous wastes generated by company activities. The practices presented were monitoring, control and the proper disposal of all waste generated;

(7) ISO 14001 Certification: only one of the analysed plants is ISO 14001 certified. This certification aims to guide and support the implementation of an environmental management system, and corroborating the fact that it is ISO 14001 certified, the Beta Plant has a specific sustainability management department;

(8) By-product reuse: the use of biofertilizers from vinasse, filter cake and soot was unanimous, indicating that polluting waste from sugarcane energy production is already being rationally reused in order to not harm the environment;

(9) Gas cleaning: the use of stack filters was found in all the analysed plants, which, apart from being economically beneficial, allows for the use of the soot as organic material. This greatly benefits the environment by reducing negative impacts.

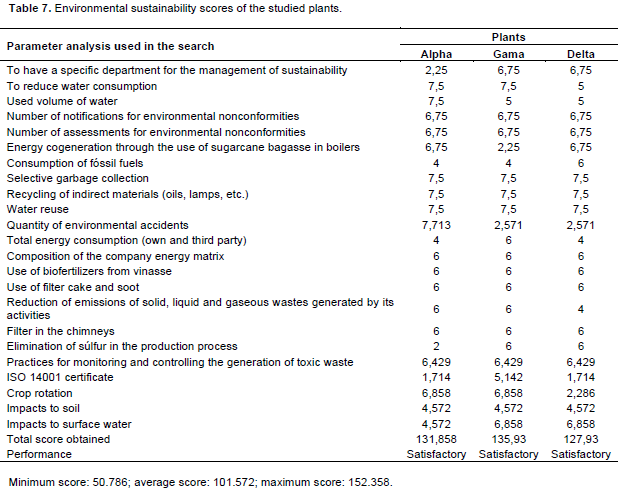

Through the identification of practices in place in the sugarcane energy industry in Mato Grosso do Sul, the total scores for the environmental dimension were calculated based on the indicators proposed by Callado and Fensterseifer's model (2011). From the sum of the overall performance of the plants concerning the environmental dimension, the Beta Plant was verified to be the one that achieved the highest total score (135.93), followed by the Alpha Plant (131.858) and Gama Plant (127.93). Interestingly, the plant with the highest score was also the one holding an ISO 14001 certification, which guides companies to incorporate the environmental variable into the broader company strategy and operational routine.

Combining performance results in the environmental dimension, the scores were calculated in two steps: first, the overall performance score was calculated by the sum of the performance of environmental parameters; second, the performances were classified as satisfactory or unsatisfactory depending on the score value range of this dimension. The results and their classifications are presented in Table 7.

The practices observed in the sugarcane energy industry in the State of Mato Grosso do Sul corroborate the results found by Chaddad (2010), Pereira and Ortega (2010) and Smeets et al. (2008), who analysed the sector nationwide. Unanimities observed regarding the appropriate use of polluting substances suggest legal pressure that employs penalties in the case of contamination. Another point to be highlighted is the practices related to the reuse of by-products, which can be justified by the economic gains resulting from this use and the assumption that some by-product can replace agrochemicals and generate electric power.

The objective of this paper was to analyse how companies in the sugarcane energy industry in the State of Mato Grosso do Sul have been handling strategic environmental management. This study brought the sustainability focus to the reality of the Brazilian agribusiness by analysing the sugarcane energy industry in the State of Mato Grosso do Sul in relation to its sustainable performance and by also considering the relevance of this sector to the local and national economy and its potential impact on the environment and on the respective stakeholders.

The results indicate that the plants in the sugarcane energy industry participating in the research tend towards instituting environmental practices, which explains the satisfactory performance achieved by applying Callado and Fensterseifer's model (2011). The plants analysed seem to be advancing through the evolutionary stages of environmental management not only by implementing those environmental practices that are required by law but especially by developing ways to monitor and to prevent possible impacts from their activities. In addition, the inclusion of the environmental variable in the plants’ strategies indicates that such sustainable actions are a source of competitive advantage.

This research has highlighted several key factors from an environmental management perspective, such as (a) the importance of an institutional environment to define, monitor, and enforce the environmental legislation; (b) the relevance of the private sector, which was highlighted by the inclusion of environmental practices into the business strategy; (c) the need, from the industry’s perspective, to address international certification requirements; and (d) from the market perspective, the increase in sustainable practices demanded by suppliers.

One of the outcomes shows that organizations are trying to address legal environmental requirements. From this perspective, improvements to the environmental regulations could lead to a modernization of environmental management. This modernization could contribute to the mitigation of environmental impacts from this industry. In addition, it could reduce the total costs as a result of the corrective actions undertaken by companies.

However, the improvement of environmental regulations needs to be sensitive and needs to take economic and social issues into consideration. One alternative is to gradually improve the regulation and to promote discussions among companies and the government in adopting environmental best practices.

From the strategic point of view, it is clear that Brazilian energy companies have to make decisions considering economic, environmental and social issues. This argument is based on the fact that this sector should be fundamentally concerned about natural resources and work conditions. Thus, the industry concern regarding environmental issues is related to its long-term survival as well as short-term economic issues.

Another area that could be improved is the adoption of organizational structures for centralized management when considering environmental issues. Environmental matters are relevant to all departments/sectors.

In addition, this paper suggests the creation of an ombudsman function related to environmental issues. In this regard, the ombudsman manages all criticism and suggestions regarding the issue, thus minimizing/eliminating environmental damage and risks that might be perceived by the community.

Furthermore, the industry might pursue the ISO 14000 Certification and support companies in addressing the certification requirements. In this regard, a company’s entry into the international market could be an incentive to address stricter environmental regulation, which may not be as attractive when only interacting with the domestic market.

Finally, the fact that a company is a member of a business group indicates that it will have better environmental management. This paper argues that, as a member of a business group, a company could acquire more knowledge about the issue, and first movers may establish a trend that others in the group tend to follow in terms of environmental issues.

For future studies, data related to sustainability should be compared from a broader perspective. This research should consider the triple bottom line of sustainability, which covers the social, environmental and economic dimensions, and the operating performance of the plants in order to evaluate the technical literature that claims that the best sustainable performance culminates in improved operating performance as well.