ABSTRACT

A field experiment was conducted at Gewane Agricultural Technical and Vocational Education and Training College in 2012/2013 to assess effect of farmyard manure and intra-row spacing on yield and yield components of Adama Red onion (Allium cepa L.) cultivar under irrigation. Factorial combination of four rates of farmyard manure (0, 10, 20 and 30 t ha-1) and four levels of intra-row spacing (7.5, 10, 12.5 and 15 cm) were arranged in randomized complete block design with three replications. Significant effect of intra-row spacing on most of plant growth, bulb yield and bulb characters studied was noticed. Similarly, farmyard manure showed significant effect on mean bulb weight, weight loss, and bulb rotting. The interaction effects of intra-row spacing and farmyard manure rates showed significant influence on biological, total, marketable and unmarketable bulb yields. Highest total bulb yield, 58.74 t ha-1 and marketable bulb yields 57.77 t ha-1 were obtained from plants spaced at 7.5 cm and plots received 30 t ha-1 farm yard manure. The highest weight loss and bulb rotting were observed at wider intra-row spacing (15 cm) and highest farmyard manure application, which was 30 t ha-1. Intra-row spacing of 7.5 cm and 20 t ha-1 farmyard manure rate gave good marketable bulb yield and better storage life under the study area.

Key words: Bulb yield; farmyard manure; intra-row spacing; storage life.

Onion (Allium cepa L.) is the most common member of the family Alliaceae and the widely grown herbaceous biennial vegetable crop. It is grown mainly for its bulb, which is used in every home, almost daily. As a constituent of a meal, both the green leaves and bulbs can be eaten raw, cooked or in soups and salads (Sani and Jaliya, 1987).

In Ethiopia,the Alliums ( onion,garlic and shallot) are important bulb crops produced for home consumption and are sources of income to many peasant farmers in many parts of the country. Onions have a wide range of climatic and soil adaptation and they are cultivated both under irrigation and rain fed conditions (Tabor and Zeleke, 2000; Rabinowitch and Currah, 2002). The crop is known to be heavy feeder of nutrients mostly supplied from chemical fertilizer which requires high expense and is potentially harmful to human health and environment (Thamburaj, 1991). Therefore, it is imperative to look for cheaper and environment friendly methods of soil fertilization. In this regard, the use of organic fertilizer, as farm yard manure, has currently attracted considerable attention to supply various nutrients to crops. Farm yard manure improves soil permeability to air and water as well as nutrient uptake. This type of fertilizer also supply nutrients, enhance moisture holding capacity and cation exchange capacity (CEC) of the soil and moderates soil pH. They also improve soil bulk density and are beneficial to micro-organism activities (Subedi, 1998). As the source of farm yard manures varied, its contents of plant nutrition also differ as per the types of livestock (cattle, poultry etc).

Plant population is important in onion production since it has an influence on growth, yield and quality of onion bulbs (Brewster, 1994). Optimum inter-row and intra-row spacing (which reduces competition between plants and enables efficient use of available crop land) varies with soil fertility status, soil moisture, the nature of the crop and degree of weed infestation (Singh et al., 1997).

The Upper and Middle Awash Valley Regions of Ethiopia is highly suitable for cash crop such as onion production and marketing (CACC, 2002). However, due to low soil fertility, salinity effect and inappropriate cultural practice the yield is low in the area (MARC, 2004). Farmers adopted spacing of 40 cm wide bed, having two rows in each bed and each row spaced 20 cm apart between rows in a bed and 10 cm between plants in a row. Application of manure rate for different reasons, they did not also adopt recommendations employed elsewhere. There is also lack of site based recommendation on plant spacing and organic fertilizer rate that can help to increase onion production and soil fertility in sustainable way. Therefore, this study was conducted with the objective of assessing the effects of farmyard manure rates and intra-row spacing on yield and yield components of Adama Red onion cultivar.

An experiment was conducted at Gewane Agricultural Technical and Vocational Training (ATVET) College Demonstration Farm, located in Gewane Woreda (10°10’ N and 40°32’ E), Afar National Regional State, about 350 km East of the capital city, Addis Ababa at an altitude of about 626 m above sea level (ESRDF, 2003). The experimental area was characterized as semi-arid climatic zone with average annual rainfall of about 400 mm which is erratic and unreliable. The soil was silt clay loam in texture with pH of 8.28 and mean annual temperature of about 32°C with ranges of 44°C, maximum to 17°C, minimum (DPPC, 2000). Adama Red cultivar and well decomposed, aged and dried FYM obtained from cattle was used. The national recommended dose of mineral fertilizer was also being applied to meet the crop demand for optimum yield. Accordingly, 100 kg ha-1 Diammonium phosphate (DAP) and 150 kg ha-1 urea was applied where half of the urea and all DAP were applied at the time of planting and the rest 50% urea applied 45 days after transplanting.

Factorial combinations of four levels of farmyard manure (0, 10, 20 and 30 t ha-1) and four intra-rows spacing of onion (7.5, 10, 12.5 and 15 cm) were used in a Randomized Complete Block Design (RCBD) with three replications. Gross plot size was 2 m × 3 m (6 m2) accommodating ten rows. The distance between plots and blocks was 1 m and 2 m apart, respectively. The outer single rows at both sides of the plot and one plant at both ends of the rows were considered as border plants. Internal single rows of the outer double row at both sides of the plot were used for destructive samples (bulb dry mass content). The remaining plants in the six center rows were used as net plot area to determine yield per plot.

Seeds of Adama Red cultivar were sown on prepared seed bed to raise seedlings. Seedlings were transplanted in the field on January 6, 2013 on shoulder of ridges adopting the recommended spacing of 40 cm wide ridges or beds and 20 cm between rows in a bed. Seedlings were grown to height of 12 to 15 cm on the nursery area and then transplanted. Other recommended cultural practices were kept uniform for all treatments. Harvesting of onion bulbs were done on May, 2013 when 70% plants show necrosis of foliage and cured for four days. Curing is drying of onion bulbs using sun light to reduce water content present in it for the purpose of reducing decays.

Data were collected on the following parameters by sampling six plants randomly from six central rows of each plot except days to maturity which was collected on plot basis.

Days to maturity

Days to maturity were the actual number of days from the transplanting to the time when 70% of plants’ foliage collapses.

Plant height and leaf length (cm)

Plant height was measured by a ruler in centimeters from the soil surface to the tip of the matured leaf; and leaf lengths were taken from three leaves plant-1 at maturity.

Leaf number plant-1

This refers to the mean number of leaves produced by sampled plants. The total number of leaves of sampled plants was counted and divided by the number of plants to get mean leaf numbers plant-1.

Neck thickness (cm)

The average neck thickness was measured at the narrowest point at the junction of bulb and leaf sheath by using verner caliper.

Bulb length and bulb diameter (cm)

The average heights of the matured bulb length and bulb diameter at the widest point in the middle portion of the matured bulb were measured by using vernier caliper.

Mean bulb weight (g)

This is the average weight of matured bulb in grams after harvest and curing. It was measured by sensitive balance.

Bulb dry mass content (%)

For determination of mature bulb dry mass content, a homogenate sample was prepared from sampled plant bulbs from each plot and those samples were chopped down, from which 300 g of the homogenate sample was taken and oven dried at temperature of 70°C to constant weight, the weight was measured using electrical balance and percent of dry matter was calculated using the formula:

Where, DMC = dry mass content; CW = container weight; FW = fresh weight.

Biological yield (g)

The biological yield was recorded as the sum of above ground parts and bulb at the time of maturity using a digital balance from the central six rows.

Marketable and unmarketable bulb yield (t ha-1)

Marketable bulb yield was determined after discarding bulbs smaller than 3 cm in diameter (Morsy et al., 2012), splitted, rotten, damaged, and discolored after topping and curing of onion crop and those bulbs other than normal and size greater than 3 cm diameter were categorized as unmarketable.

Total bulb yield (t ha-1)

It was recorded from central six rows per net plot. The harvested both marketable and unmarketable bulbs yield were weighed after curing and the yield was converted into t ha-1.

Bulb storage life

Cumulative loss in weight, extent of rotting, sprouting and firmness in percent was recorded at interval of two weeks for three months, keeping 60 bulbs from each treatment spread on floor at ambient condition. The storage period was from May 11 to August 8, 2013. The following were some of quality parameters of bulb storage life.

Bulb weight loss (%)

Percent weight loss was determined according to Waskar et al. (1999). The weight loss data were calculated from 60 bulbs which were randomly taken per treatment and weighed at the beginning and middle of each month.

Where, wi = initial weight, and wf = final weight.

Sprouting and rotting bulbs (%)

Percent of bulb sprouting and rotting was taken based on the number of bulbs sprouted and decayed in two weeks assessment. Data on sprouting and rotting was recorded by counting the number of bulbs that were sprouted and rotted. The sprouted and decayed bulbs were discarded after each count to avoid double counting. Bulbs that sprouted and rotted at the same time were classified as sprouted.

The data collected were subjected to analysis of variance (ANOVA) using SAS software version 9.0. GLM procedures and least significant difference (LSD) was used to separate means at p < 0.05 probability levels of significance.

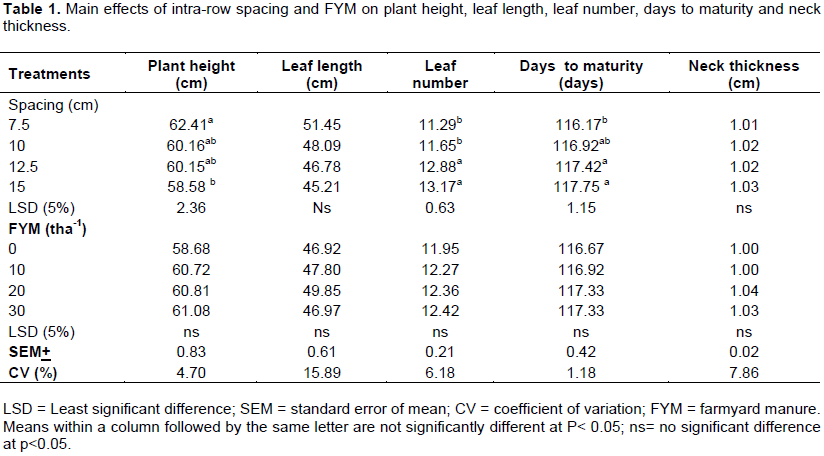

Days to maturity and leaf number

The influence of intra-row spacing revealed significant variation (p<0.05) on maturity of onion and leaf number while farm yard manure (FYM) and their interaction did not show significant differences (Table 1). Closer plant spacing enhanced maturity (116.17 days) while wider plant spacing (15 cm) showed slightly delayed maturity. Maximum leaf number plant-1 (13.17) was obtained from plants spaced at 15 cm followed by those spaced at 12.5 cm intra-row spacing. On the other hand, 7.5 cm spaced plants gave the minimum number of leaves plant-1 (11.29) that did not vary statistically from plants spaced at 10 cm apart, which gave 11.65 leaves plant-1. Wider spacing that allowed plant to have access to more nitrogen which prolonged maturity and higher number of leaves. While in closer spacing, plant competes for light, nutrient and moisture causing early bulb maturity and reduced leaf number (Brewster, 1990, 1994). Brewster (1994) and Belay et al. (2015) noted that bulb maturity was advanced by higher planting density, which was associated with a high leaf area index and hence high light interception by the leaf canopy that advanced the date of bulb scale initiation.

Plant height, leaf length and neck thickness

Plant height was affected by intra-row spacing (P<0.05) but not by farmyard manure and their interaction (Table 1). Maximum plant height (62.41 cm) was recorded when plants were spaced at 7.5 cm distance, followed by plants spaced at 10 and 12.5 cm with no significant difference among them. The lowest plant height (58.58 cm) was recorded at spacing of 15 cm which was also at par with the 10 and 12.5 cm intra-row spacing (Table 1).

In general, as intra-row spacing increased from 7.5 to 15 cm, plant height showed decreasing trend. This might

be due to less competition for light in wider spacing and higher competition occurred in closer plants. Kitila et al. (2012) reported that closer spacing of 30 cm resulted in better plant height of tomatoes. Khan et al. (2002) also observed higher plant height in plants spaced at 12 cm distance than in plants spaced at 15 cm distance. Similarly, Gedamu (2005) noted that increased plant height and leaf length was observed at narrower row spacing in garlic. On the other hand, leaf length and neck thickness were not affected by intra-row spacing, FYM rate and their interaction (Table 1).

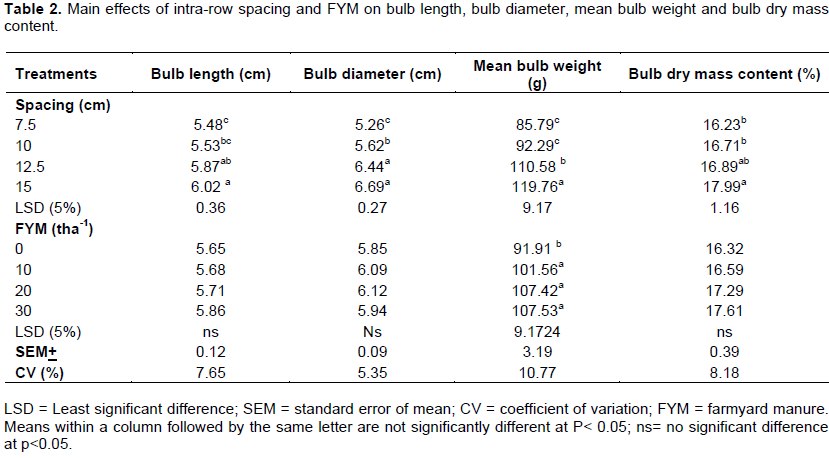

Bulb length, bulb diameter and bulb dry mass

There was significant effect of intra-row spacing (P<0.05) on onion bulb length but FYM and its interaction with intra-row spacing did not significantly influence bulb length, bulb diameter and percent bulb dry mass (Table 2). Higher bulb length (6.02 cm) was observed from plants planted in wider spacing (15 cm) followed by those planted at 12.5 cm while significantly smaller bulb length (5.48 cm) was obtained from closer spacing (7.5 cm), which was also statistically similar to those planted at 10 cm spacing (Table 2). The increase in bulb length by 9% as intra-row spacing increased from 7.5 to 15 cm could be attributed to adequate availability of growth resources at wider spacing that allows the bulbs to have more assimilates available for storage and thus resulted in higher bulb length. Dawar et al. (2007) reported that generally high planting density results in less availability of soil nutrients, water, light, etc; and that due to these, bulbs do not attain their potential sizes.

The highest bulb diameter (6.69 cm) was recorded from intra-row spacing of 15 cm followed by 12.5 cm which resulted in bulb diameter of 6.44 cm while significantly minimum bulb diameter of 5.26 cm was obtained from closer spacing of 7.5 cm (Table 2). The lack of available space for closer intra-row spacing could account for decrease in bulb diameter. Akoun (2004) reported that there was a marked increased in the diameter of onion bulbs as plant population decreased. Wider intra-row spacing of 15 cm resulted in higher bulb dry mass content (17.99%) while closer spacing (7.5 cm) gave the lowest bulb dry mass content (16.23%). This might be due to wider spacing allows the plants to uptake nutrients and accumulates higher dry matter. The result is in agreement with that of Ademe et al. (2012) who reported that shallot bulbs planted at 20 cm intra-row spacing produced greater bulb dry mass content plant-1 than those planted at 15 and 10 cm intra-row spacing. Abubaker (2008) also reported that pod dry weight of bean tended to be higher under the lower plant density. In crop plants, dry matter accumulation is a result of nutrient uptake and one of the measures of plant growth (Noggle and Fritz, 1983).

Mean bulb weight

Analysis of variance showed that mean bulb weight was highly affected (p<0.001) by intra-row spacing and FYM rates but not by their interaction (Table 2).The highest mean bulb weight (119.76 g) was recorded from 15 cm spaced onion plants followed by 12.5 cm spaced plants which, however, did not vary statistically. On the other hand, the least mean bulb weight (85.79 g) was obtained from the treatment of 7.5 cm intra-row spacing (Table 2).

In general, with increase in plant spacing, from 7.5 to 15 cm, mean bulb weight increased from 85.79 to 119.76 g. This might be due to the fact that closer spacing between plants resulted in competition for nutrients, moisture and light, thus reducing amount of assimilate stored in the bulbs which reduced their bulb weight. This result is similar with Khan et al. (2002) who reported that plants spaced at 9 cm gave the lowest average weight for a single onion bulb while in 15 cm spaced plants, the weight of the bulb was maximum. Similar result was also reported by Ademe et al. (2012) where bulbs of ‘Huruta’ shallot planted at 20 cm intra-row spacing produced the highest bulb weight plant-1 while those planted at 10 cm intra-row spacing produced the lowest bulb weight plant-1.

Farm yard manure application improved mean bulb weight compared to the control where FYM was not applied (Table 2). The increased in mean bulb weight at FYM rates of 10, 20 and 30 t ha-1, respectively, which might be attributed to solubilization of plant nutrients by addition of FYM leading to increase in uptake of plant nutrients or it could be the ability of manure in creating suitable plant growing environment by improving moisture and nutrient status of the soil (Subbaiah et al., 1982). The result is in line with the finding of Eifediyi et al. (2010) who reported that fruit weight in cucumber increased with increase in the rate of FYM applied from 0 to 10 t ha-1. Similarly, Zaharah et al. (1994) reported that when palm oil mill effluent was applied as organic component to soil in Malaysia, there was increase in bulb size of onion. Fisseha (2010) reported that with application of 20 t ha-1 FYM was about 32.9% higher than the bulb weight from the control.

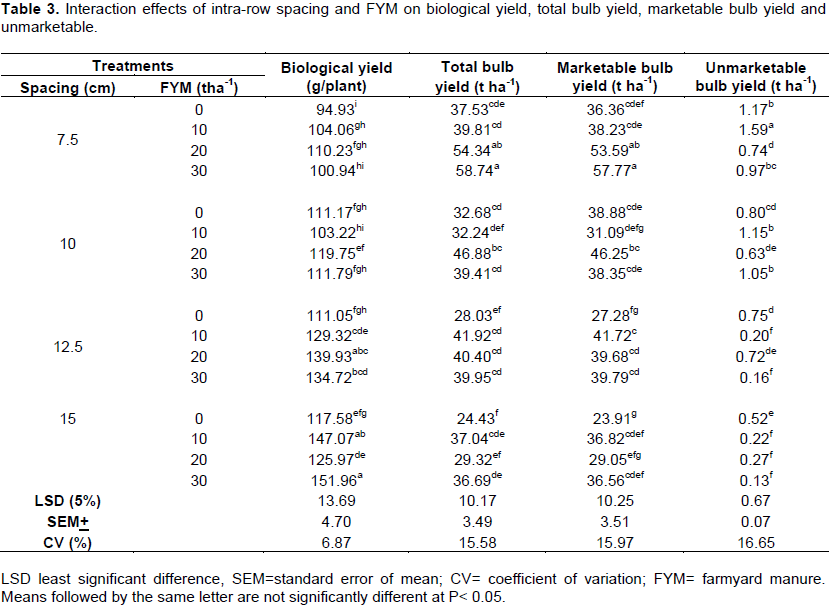

Biological yield, total bulb, marketable and unmarketable bulb yield

Biological yield, total bulb, marketable and unmarketable bulb yield of onion was significantly affected by intra-row spacing, FYM and their interaction (Table 3). The highest biological yield (151.96 g plant-1) was obtained from wider spacing of 15 cm combined with 30 t ha-1 FYM, which is about 60% higher over the biological yield recorded from 7.5 cm intra-row spacing combined with no FYM (Table 3). The highest total (58.74 t ha-1) and marketable (57.77 t ha-1) bulb yield was obtained from the treatment combination of narrower spacing of 7.5 cm and higher rate of FYM (30 t ha-1), followed by same spacing treatment combined with FYM of 20 t ha-1. Compared to the treatment of 15 cm intra-row spacing with no FYM applied, the minimum recorded total bulb yield was (24.43 t ha-1) and for marketable bulb yield (23.91 t ha-1), resulted in the increment of about 140.4 and 141.6%, respectively (Table 3).

The highest unmarketable bulb yield (1.59 t ha-1) was obtained from treatments combinations of intra-row spacing of 7.5 cm and FYM rate of 10 t ha-1, followed by 7.5 cm combined with no FYM which resulted in 1.17 t ha-1 while the least values were recorded from treatment combinations of 12.5 or 15 cm inter-row spacing with 30 t ha-1 FYM (Table 3). The increased in biological yield at wider spacing and higher rate of FYM might be due to increased bulb length, bulb diameter, leaf number, and mean bulb weight and due to accumulation of more assimilates in the bulbs. This finding is in conformity with the finding of Ademe et al. (2012) who reported that shallot bulbs planted at 20 cm intra-row spacing grew more vigorously and obtained more biological yield plant-1 than those planted at 10 cm spacing.

In the present study, application of FYM regardless of spacing variation showed 11.2 to 14.9% increase in biological yield compared to the control treatment. The increase in total and marketable bulb yield was due to application of farmyard manure are largely attributed to improved soil organic matter, soil physical, chemical and microbial properties that enhance plant growth as well nutrient availability and its uptake by the plants (Eifediyi et al., 2010). In agreement with this, Fisseha (2010) reported that application of 20 t ha-1 FYM gave about 33% more biological yield compared to non manured plots. Mekonnen (2006) has shown that marketable potato tuber number was increased as the rates of both FYM and vermicompost increased from 5 to 10 t ha-1 and 4 to 8 t ha-1, respectively. Kokebe et al. (2013) found that the combined application of 150 kg ha-1 of N and 30 t ha-1 of FYM gave the maximum dry bulb of onion.

Satyanarayana and Prasad (2002) reported that organic manure plays an important role in improving soil permeability to air and water and water stable aggregates. Thus application of organic materials such as farmyard manure considerably improves soil physical properties and nutrient uptake resulting in greater growth, yield and yield components. Akoun (2004) has shown that increasing the rate of manure application from 5.6 to 22.4 t ha-1 caused significant difference in yield. The highest yield of 9.55 t ha-1 was obtained with application of 22.4 5.6 t ha-1. Unlike chemical fertilizer that supplies only the major nutrients, farmyard manure is a store house of several other plants nutrients and act as a good soil conditioner (Mishra and Nayak, 2004).

The result is in agreement with the work of Bosekeng (2012) who reported that plants that are highly populated tend to produce high yield of small bulbs, whereas plants at low population produce larger bulbs but with low yield. Kahsay et al. (2013) observed that as intra-row spacing increased from 5 to 10 cm, marketable bulb yield decreased from 34.49 to 28.1 t ha-1. Awas et al. (2010) also reported that, amongst the cultivars and plant density tested, Nasik Red at intra-row spacing of 4 cm earned the maximum bulb yield followed by Bombay Red planted at similar spacing while Adama Red at intra-row spacing of 10 cm (wider spacing) and 8 cm gave the lowest average total bulb yield.

The high unmarketable yield in closely spaced plants could be due to inter-plant competition that resulted in a fewer large sized bulbs than wider spacing that negatively affected the marketable yield and favored the production of small sized bulbs that were unmarketable. Lower unmarketable yield in higher rate of FYM and wider spacing, on the other hand, could be due to less competition for nutrients and space which results in larger bulbs which were marketable. This is in agreement with the result of Ademe et al. (2012) who reported that shallot bulbs of ‘Huruta’ planted at 10 cm intra-row spacing produced the highest unmarketable yield ha-1 while at 20 cm intra-row spacing, the lowest unmarketable yield ha-1 were produced.

Bulb storage life

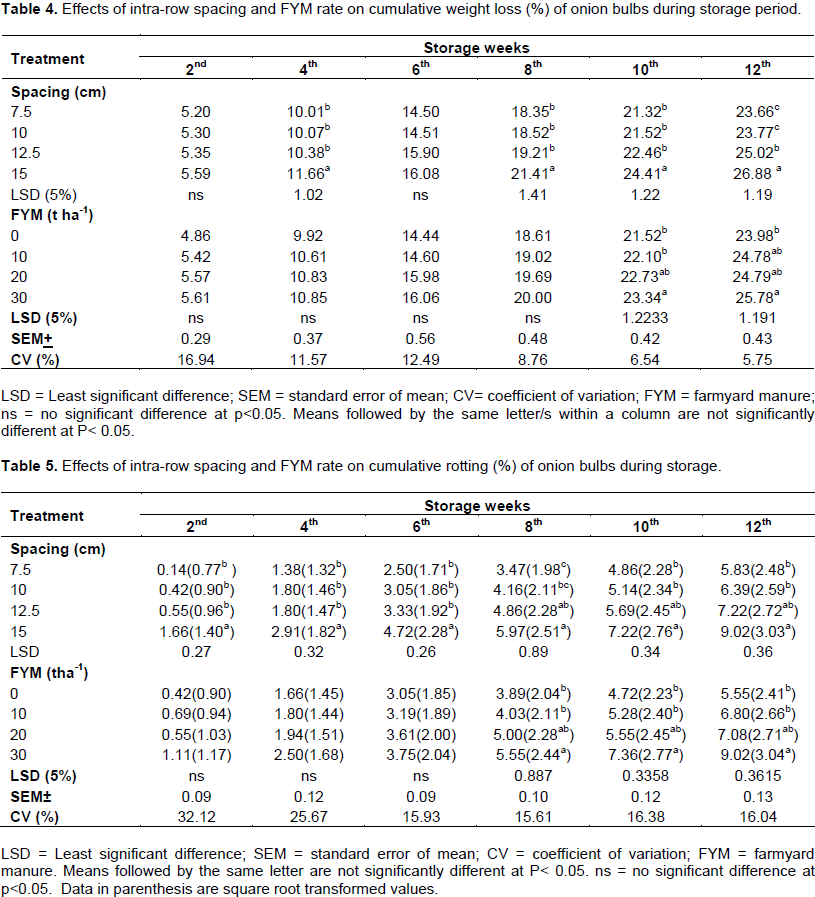

Bulb weight loss and bulb rotting

Onion intra-row spacing significantly (p<0.05) affected bulb weight loss (%) and bulb rotting of onion most part of the storage period (Tables 4 and 5). As the storage period extended, the cumulative bulb weight loss increased due to increase in water loss, rotting and sprouting. Higher weight losses during the 12 weeks of storage were observed in wider spacing (15 cm) than in bulbs from narrower spacing treatments (Tables 4 and 5). At the 12th week, bulb weight loss reached 26.88% in bulbs from 15 cm spacing while the least bulb weight losses were observed from 7.5 cm (23.66%) and 10 cm (23.77%) spaced plants. Higher bulb weight loss and rotting at wider spacing could be attributed to large bulb size with succulent tissues and thicker necks which are vulnerable to rotting, sprouting and water loss during storage period. Sing and Sing (2003) reported that, large size bulbs exhibited the highest weight loss compared to smaller sized bulbs. In agreement with the present result, Kahsay et al. (2013) reported that weight loss and rotting of bulbs from the widest spacing (10 cm) and the least spacing (5 cm) were greater than that of the middle one (7.5 cm). Similarly, Bosekeng (2012) reported that bulbs harvested from population of 95 plants m-2 lost significantly less moisture (9.83%) than bulbs from population of 61 plants m-2 (22.67%).

Application of FYM did not significantly affect bulb weight loss (%) and bulb rotting (%) until 8th and 6th weeks of storage period respectively. However, during 10th and 12th week of storage period, significant (p<0.05) weight loss of onion bulbs was observed between the FYM rates (Table 4). Rotting of bulbs from the 8th week of storage period onwards, was significantly affected by FYM (p<0.05) (Table 5). The highest bulb rotting was observed in treatment received 30 t ha-1 while the least bulb rotting was recorded in control which, however, did not vary statistically from those which received FYM at the rates of 10 and 20 t ha-1 (Table 5). The increase in percent bulb weight loss and rotting at higher rate of FYM could be due to improvement of soil physical and chemical properties, including addition of macro and micro nutrients which resulted in larger bulb size with succulent tissue prone to rotting. Zewude et al. (2010) observed that an increased in weight loss and rotting was due to increase in nitrogen rate. The increase in percent weight loss and rotting of bulbs due to increase in nitrogen could be attributed to the fact that higher rates of nitrogen encouraged plants to produce large bulbs with soft succulent tissues which make them susceptible to the attack of disease causing micro organisms.

Farmyard manure improves soil physical property, like reduced bulk density that allows the bulb to expand more, and improve supply of macronutrients which increases bulb size and thereby increasing the proportion of bulb neck thickness that favors bulb sprouting and loss of reserve carbohydrate and moisture. Syed et al. (2001)

noted that small bulbs showed minimum weight loss (0.23%) while greater loss was noted in large bulbs (5.56%) after a storage period of 16 days. Agasimani (2010) observed that NPK + FYM tended to develop soft tissues with high moisture content which in turn rendered bulbs to higher storage loss in onion. Eze and Orkwor (2010) reported that the application of fertilizer (organic or inorganic) increased weight loss in yam varieties compared to where it was not applied, although difference was not statistically significant.

Bulb sprouting

Significant differences in sprouting bulbs were not observed between intra-row spacing, FYM rate and their interactions. Sprouting of bulbs was not observed until 8th weeks of storage. Absence of bulb sprouting at early stage could be attributed to the high temperature, low relative humidity, curing treatment which inhibits sprouting. Inherent characters of dormancy based on equilibrium of inhibitors in onion bulbs can be affected by temperature where lower and higher temperatures increase the dormant state of onion bulbs and moderate (10-15°C) temperature enhanced the sprouting by breaking dormancy (http://www.nhrdf.com). No sprouting occurs at storage temperature between -1 and 1°C or between 25 and 30°C (Miedema, 1994). But at 10th and 12th weeks of storage period, bulb sprouting was observed.

Onion is grown mainly for its bulb, which is used in every home daily. The upper and middle awash valley regions of Ethiopia have privileged position for production and marketing of onion as a cash crop. Onion yield in this region remained low, due to several factors, including low soil fertility, salinity effect and inappropriate cultural practices. A study was undertaken to assess the effect of intra-row spacing and application of farmyard manure (FYM) on yield and quality of Adama Red onion cultivar in Gewane, lower Rift Valley of Ethiopia.

The interaction effects of intra-row spacing (15 cm) and FYM (30 t ha-1) gave the highest biological yield (151.96 g plant-1), which was about 60% increase over the minimum biological yield recorded from 7.5 cm intra-row spacing combined with no FYM. The highest total (58.74 t ha-1) and marketable bulb yields (57.77 t ha-1) were obtained from the treatment combination of narrower spacing of 7.5 cm and higher rate of 30 t ha-1 FYM.

Higher weight losses during the 12 weeks of storage were observed in wider spacing (15 cm) than in bulbs from lower spacing treatments. The highest percent of bulb rotting was observed in plants planted at wider spacing (15 cm) while the least bulb rotting was observed in closer spacing (7.5 cm). Highest rate of FYM had increased bulb deterioration in storage period in all bulb storage life studied. Due to application of recommended dose of mineral fertilizer, FYM did not show significant difference in most parameters.

Onion intra-row spacing of 7.5 cm and 20 t ha-1 farmyard manure rate gave good marketable bulb yield and better onion storage life which can be stored for about three months. Highest rate of farmyard manure had increased bulb deterioration in storage period in all bulb storage life. As storage time extended, cumulative bulb weight loss, bulb rotting and sprouting increased.

The authors have not declared any conflict of interests.

REFERENCES

|

Abubaker S (2008). Effect of plant density on flowering date, yield and quality attribute of Bush Beans (Phaseolus Vulgaris L.) under Center Pivot Irrigation System. Am. J. Agric. Biol. Sci. 3(4):666-668.

Crossref

|

|

|

|

Ademe D, Belew D, Tabor G (2012). Influence of bulb topping and intra row spacing on yield and quality of some shallot (Allium Cepa Var. Aggregatum) varieties at Aneded woreda, western Amhara. Afr. J. Plant Sci. 6(6):190-202.

|

|

|

|

|

Agasimani PKD (2010). Studies on organic farming practices in onion (Allium cepa). MSc. Thesis, Dharwad Universty, Dharwad, India.

|

|

|

|

|

Akoun J (2004). Effect of plant density and manure on yield and yield components of common onion (Allium cepa L.) Var. Nsukka Red. Nig. J. Hort. Sci. 9:43-48.

|

|

|

|

|

Awas G, Abdisa T, Tolesa K, Chali A (2010). Effect of intra-row spacing on yield of three onion (Allium cepa L.) varieties at Adami Tulu agricultural research center (mid rift valley of Ethiopia). J. Hort. For. 2(1):007-011.

|

|

|

|

|

Belay S, Mideksa D, Gebrezgiabher S, Seifu W (2015). Effect of intra row-spacing on growth and yield components of 'Adama red' onion (Allium cepa L.) under irrigation in Fiche, North Shoa, Ethiopia. J. Harmonized Res. Appl. Sci. 3(4)231-240.

|

|

|

|

|

Bosekeng G (2012). Response of onion (Allium cepa L.) to sowing date and plant population. MSc. Thesis, University of Free State, Bloemfontein, South Africa.

|

|

|

|

|

Brewster JL (1990). Cultural systems and agronomic practices in temperate climates. pp. 2- 30. In: Rabinowitch HD, Brewster JL (Eds.). Onions and allied crops. 2. Agronomy, biotic interactions, pathology, and crop protection.CRC Press, Boca Raton, Florida, USA.

|

|

|

|

|

Brewster JL (1994). Onions and other vegetable Alliums. CAB, International, Wallingford, UK. 236 p.

|

|

|

|

|

CACC (Central Agricultural Census Commission part I) (2002). Report on preliminary result of area, production and yield of temporary crops. Addis Ababa. 200p.

|

|

|

|

|

Dawar NM, Wazir FK, Dawar M, Dawar SH (2007). Effect of planting density on growth and yield of onion varieties under climatic conditions of Peshawar. Sarhad J. Agri. 23(4):911-918.

|

|

|

|

|

DPPC (Disaster Prevention and Preparedness Commission) (2000). Food supply prospect in 2000, DPPC, Early warning system report.3, Addis Ababa, Ethiopia.

|

|

|

|

|

Eifediyi EK, Remison SU, Okaka VB (2010). The effects of farmyard manure on the dry matter components of two cucumber varieties. J. Nature Sci. 8(5): 16-22.

|

|

|

|

|

ESRDF (Ethiopia Social Rehabilitation Development Fund) (2003). Integrated Gewane Woreda development plan for 10 years (2003–2013). Afar Regional Office, March 2003.

|

|

|

|

|

Eze SC, Orkwor GC (2010). Studies on effects of mineral fertilizer, organic manure and cultivar on the yield and storability of Yam (Dioscorea rotundata Poir). Afr. J. Food Agri. Nutr. Dev. 10(6):2755-2771.

Crossref

|

|

|

|

|

Fisseha M (2010). Response of onion (Allium cep var. cepa) to combined application of farmyard manure and inorganic nitrogen and phosphorous fertilizer at Alage, Ethiopia. MSc. thesis, Haramaya University, Ethiopia.

|

|

|

|

|

Gedamu F (2005). Effects of clove size and plant density on the bulb yield and yield components of garlic (Allium sativum L.) in Awabel woreda, Eastern Gojjam zone. MSc. thesis, Haramaya University, Ethiopia.

|

|

|

|

|

Kahsay Y, Abay F, Belew D (2013). Intra-row spacing effect on shelf life of onion varieties (Allium cepa L.) at Aksum, Northern Ethiopia. J. Plant breeding crop Sci. 5(6):127-136.

|

|

|

|

|

Khan H, Iqbal M, Ghaffoor A, Waseem K (2002). Effect of various plant spacing and different nitrogen levels on growth and yield of onion (Allium cepa L.). J. Biol. Sci. 2(8):545-547.

Crossref

|

|

|

|

|

Kitila M, Belew D, Mohammed A, Getachew Y (2012). Effect of intra -row spacing and variety on fruit yield and quality of fresh market tomato (Lycopersicon esculentum Mill.) under Jimma condition, Ethiopia. Ethiopia J. Sci. Technol. 3(1):32-42.

|

|

|

|

|

Kokebe W, Belew D, Debela A ( 2013). Effect of farmyard manure and nitrogen fertilizer rates on growth, yield and yield components of onion (Allium cepa L.) at Jimma, Southwest Ethiopia. Asian net work for scientific information. Asian J. Plant Sci.

View. accessed on 20/10/2016.

|

|

|

|

|

MARC (Melkassa Agricultural Research Center) (2004). Progress report for 1995–2003. EARO, Ethiopia.

|

|

|

|

|

Mekonnen D (2006). Effects of integrated nutrient management on agronomic performance of potato (Solanum tuberosum. L.) and fertility of nitosol at Bako. MSc Thesis, Alemaya University, Ethiopia.

|

|

|

|

|

Miedema P (1994). Bulb dormancy in onion. The effects of temperature and cultivar on sprouting and rooting. J. Hort. Sci. 69:29-39.

Crossref

|

|

|

|

|

Mishra BB, Nayak KC (2004). Organic farming for sustainable agriculture. Orissa reviewed. 43 p.

|

|

|

|

|

Morsy MG, Marey RA, Karam SS, Abo-Dahab AM (2012). Productivity and storability of onion as influenced by the different levels of NPK fertilization. J. Agri. Res. Kafer El-Sheikh Univ. 38(1):171-187.

|

|

|

|

|

Noggle GR, Fritz GR (1983). Introductory Plant Physiology 2nd edition. Prentice Hall Inc. Engle Wood Cliffs New Jersey. P 625.

|

|

|

|

|

Rabinowitch HO, Currah L (2002). Allium Crop Science: Recent Advances. CABI Publishing. U.K. 585 p.

Crossref

|

|

|

|

|

Sani BM, Jaliya MM (1987). Onion production and management under irrigation. Extension bulletin. 204. Agric. Engineering series. 5. Produced and distributed by national agricultural extension and research liaison service, Ahmadu Bello University Zaria.

|

|

|

|

|

Satyanarayana V, Prasad PV (2002). Influence of integrated use of farmyard manure and inorganic fertilizers on yield and yield components of irrigated lowland rice. J. Plant Nutr. 25(10):2081-2090.

Crossref

|

|

|

|

|

Sing AK, Sing V (2003). Combined effect of set size and planting distance on kharif onion bulb. Indian J. Agri. Res. 37(41):287-290.

|

|

|

|

|

Singh BB, Chamblis OL, Sharma B (1997). Advance in cowpea research. Publication of International Institute of Tropical Agriculture and Japan International Research Center for Agricultural Science, Ibadan Nigeria.

|

|

|

|

|

Subbaiah K, Helkaih J, Ravikumar V, Rajagopal S (1982). Effect of combined application of organic and inorganic fertilizers on the yield and nitrogen uptake of MDV chilli. South Ind. Hort. 30:45-47.

|

|

|

|

|

Subedi KD (1998). Relay-planted green manures as substitute for inorganic fertilizers for rice in the intensive cropping systems in Nepal. Trop. Agric. (Trinidad). 75:422-427.

|

|

|

|

|

Syed N, Manir M, Alizai AA, Ghaffoor A (2001). Onion shelf life as a function of the levels of nitrogen and potassium application. J. Biol. Sci. 1(2):71-73.

Crossref

|

|

|

|

|

Tabor G, Zeleke A (2000). Research achievements in garlic and shallot. EARO, Addis Abeba, Ethiopia. Research Report. 36.

|

|

|

|

|

Thamburaj S (1991). Effect of nitrogen source, rate and application frequency on yield and quality of onion. Hort. Sci. 26:490-491.

|

|

|

|

|

Waskar DP, Khedlar RM, Garande VK (1999). Effect of postharvest treatment on shelf life and quality of pomegranate in evaporative cool chamber and ambient conditions. J. Food Sci. Tech. 2(36):114-117.

|

|

|

|

|

Zaharah A, Vimala P, Zainab RS, Salbiah H, Midmore DJ (1994). Response of onion and shallot to organic fertilizer on bris (Rudua series) soil in Malaysia. International symbosium on Alliums for the trpics Bangkok, Thailand. Acta Horticulturae.358:429- 432.

Crossref

|

|

|

|

|

Zewude S, Woldetsadik K, Workneh TS (2010). Effect of nitrogen levels, harvesting time and curring on quality of shallot bulb. Afr. J. Agri. Res. 5(24):3342-3353.

|

|