ABSTRACT

The present study describes and evaluates a new tool for disinfesting maize grain from weevils using heat from boiling water. In developing countries, rural farmers lose huge amounts of grain due to weevils. Cost of insecticides and resistance of grain weevils to current insecticides are major threats. The grain losses affect the nutritional status and general quality of life of rural communities. Most grain is infested by weevils while in the field before harvest, therefore disinfestation of grain before storage is crucial. The equipment was made from 0.3 mm galvanized sheets and consisted of an inner pot for holding grain, outer pot for boiling water and a two litre metal cup. The most common maize variety grown in Zimbabwe, infested predominantly with Prostephanus truncatus and Sitophilus zeamais was used to evaluate the equipment. Empty maize cobs (after removing the grain) were used as source of heat. The equipment achieved 100% mortality of both species of weevils at 48°C (when grain became hot to the palm) after approximately 30 min of maize exposure to boiling water. There was no loss in grain viability as there was no significant (χ2 =1.4, df=1, p>0.05) difference in germination between treatment and control seeds. The equipment has a number of advantages. There are no health hazards which are normally associated with direct chemical treatment, especially when farmers apply higher doses of insecticide than recommended in an effort to prevent grain losses. Farmers will use empty cobs as source of heat. The equipment can be made locally by the rural farmers. The equipment has the potential to disinfest other small grains.

Key words: Boiling water, maize weevils, heat, economic losses, germination, empty cobs, rural farmers.

Insect pests cause heavy economic losses to stored grains throughout the world and their impacts are more devastating in poor countries (Boxall, 2002; FAO, 2016) where these losses are of serious nutritional and economic importance (Tefera, 2012). The insect pests which cause damage to stored grains are beetles (Coleoptera) and moths (Lepidoptera) with beetles being more distructive to stored grain in comparison to moths (Upadhyay and Ahmad, 2011).

In rural Africa, smallholder farmers’ losses caused by the weevils Sitophilus zeamais on maize have been worsened by the introduction in the late 1970s of a neotropical pest, Prostephanus truncatus onto the continent (Hill et al., 2002). According to Mvumi et al. (2006), the pest complex of stored maize in Zimbabwe like in most countries in sub-Saharan Africa comprises of the cosmopolitan maize weevil, S. zeamais, Angoumois grain moth Sitotroga cerealella, and the less cosmopolitan larger grain borer (LGB), P. truncatus, among others. These pests attack a range of stored products, from small grains to maize, and even cassava. Some of these pests start infesting cereals in the field before harvest (Sori and Ayana, 2012). In the absence of stored crops, the natural vegetation is an important reservoir of P. truncatus, where it is capable of breeding and surviving in the dead wood of some tree hosts, some of which are actually used in the construction of grain stores (Nang’ayo et al., 2002). Of the above-mentioned stored product pests, P. truncatus is the most destructive in Zimbabwe, followed by the maize weevil. In some parts of Africa, losses as high as 50% have been reported on stored maize due to P. truncatus and S. zeamais in recent decades (FAO, 2016). Unlike the maize weevil that is an indigenous pest in Zimbabwe, LGB was first recorded in the country around 2006 and only declared as present by the government in 2010 and by that time the pest had spread to many parts of the country (Nyagwaya et al., 2010).

Although insecticidal control is still the most widely used (Benhalima et al., 2004); other strategies whose efficacy has been studied include use of plant products, inert dusts. There is often a misconception that other insecticides, especially botanicals, are safer than synthetic products (Odeyemi et al., 2008). Several leguminous plants widely used as broad spectrum insecticides are extremely toxic to aquatic life and show some level of toxicity to mammals. Charleston et al. (2005), reported that neem and Chinaberry plant extracts effectively controlled diamondback moth with no negative effect. As a requirement, detailed information on the mammalian toxicity and residual effect of botanicals should be provided before their use as insecticides (Odeyemi et al., 2008). Integrated pest management (IPM) which is essentially a holistic approach to pest control aimed at optimising the use of two or more methods for the management of pests is strongly encouraged (Dent, 2000; Odeyemi et al., 2008).

The trade in illegal and counterfeit public health pesticides is also a major concern in the region, which requires adequate legislation and capacity for enforcement as well as intersectoral and cross-border collaboration. In 2001, FAO/WHO estimated that around 30% of pesticides marketed in developing countries, with an estimated value of US$ 900 million annually, did not meet internationally accepted quality standards (FAO/WHO, 2001).

Control efforts over the years have come to rely solely on the use of synthetic insecticides in the form of fumigants or as grain protectants. However, the use of some of the traditional registered grain protectants has been reported to be ineffective on many occasions against these pests. This has led to farmers using higher doses of insecticide than recommended in a bid to try and curb storage losses caused by stored product pests. The high doses have in turn created a selection pressure against the pests leading to development of insect strains that are resistant to the insecticides. Giga and Mazarura (1990) reported that natural populations of S. zeamais showed malathion resistance of up to six-fold compared to a susceptible laboratory strain.

Despite the existence of stringent LGB-specific phytosanitary measures in international trade the bostrichid is now established in nearly all of sub-Saharan Africa including Zimbabwe (Kasambala and Chinwada, 2011). The favourable climatic conditions and poor storage systems in Africa often favours growth and development of these pests, resulting in considerable crop losses. For example, losses as high as 40% are reported on stored maize due to P. truncatus and S. zeamais and in Africa, where subsistence grain production supports the population, such grain losses may be substantial. With increasing pressure to avoid the use and minimise the choice of organophosphorus insecticides or fumigants on potential foodstuffs due to concerns about residues and human health, there is a need to find equivalently rapid non-chemical means of disinfesting grain, particularly for organic use (FAO/WHO, 2001). Fumigants have a limitation in that they fail to sterilize eggs of grain weevils (Das et al., 2013).

Temperature treatment of stored grains has been described as the best physical method which successfully kills several life stages of insects at a time (Upadhyay and Ahmad, 2011). According to Fields and White (2002) heat treatment for insect pests has been used for many years under different methods and situations. Heat has also been used extensively for fruit disinfestation, using both forced air and hot water (Hansen et al., 1992). Vapour heat has been demonstrated as effective for disinfestation of cut flowers and foliage (Hansen et al., 1992). Many approaches to heat disinfestations of stored products have been developed in the past (Beckett et al., 2007). The use of radio frequency heating, both with and without additional heating (Janhang et al., 2005), has been evaluated for the treatment of insects in rice and nuts.

Different insect species have been reported to have different heat tolerance ranges. A study of desert Drosophila species (Stratman and Markow, 1998) showed greater tolerance of high temperature by some species, but it was not consistent across all species and even the most tolerant conformed to the general rule of being within 45 to 51°C. Some studies have shown that insect mortality in grain can be achieved at lower grain temperatures but with longer exposure time which is also influenced by the moisture content of the grain (Beckett et al., 1998; Yan et al., 2014; Lu and Zhang, 2016). Beckett et al. (1998) studied the effects of both grain temperature and moisture content on the mortality of Rhyzopertha dominica and Sitophilus oryzae L. and concluded that the effects on insect mortality of grain moisture content within the range suitable for stored grain are small compared to the temperature effects. It was therefore the purpose of this study to develop and evaluate a simple equipment for use by rural communities in disinfecting stored grain products.

Description of equipment

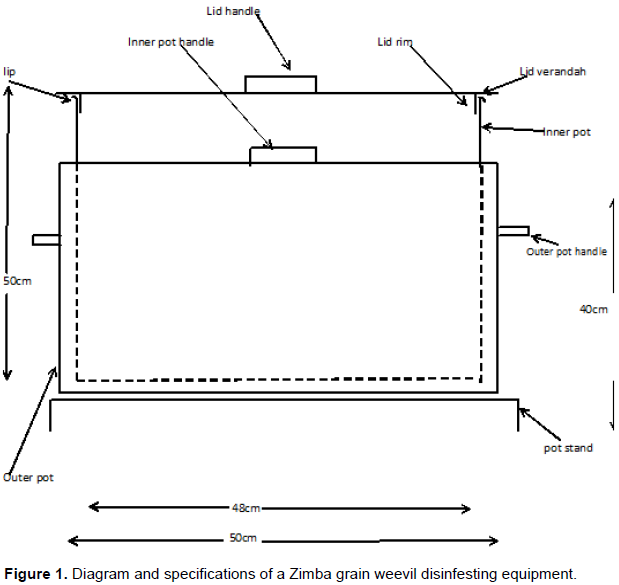

The Zimba grain weevil killer was produced at a cost of USD 60.00. The equipment makes use of boiling water to kill weevils in grain. It consists of an outer pot for boiling the water, an inner pot for holding the grain, a lid, a two litre metal cup and a square stand (Figure 1). Figure 2 shows a picture of the equipment. The pots are made of galvanized metal, 0.3 mm thick. The outer pot has a diameter of 50 cm and a height of 40 cm and has two handles at the rim. The inner pot has a diameter of 48 cm and a height of 50 cm and has a rim which is folded to form a lip which prevents steam from entering inside it (Figure 1). The inner pot has two handles with the lower part of the handles situated at 39 cm from the bottom so that when the inner pot is placed inside the outer pot, the lower parts of the handles rest on the rim of the outer pot in such a way that the inner pot is suspended 2 cm above that of the outer pot (Figure 1). The equipment uses 2 L of water resulting in a depth of 2 cm when poured into the outer pot. The function of the space between the bases of the two pots is to allow free movement of boiling water and steam. The lid has a fitting rim 1 cm wide and a protruding verandah 2 cm wide to aid in preventing entry of steam into the grain. The stand has sides of 52 cm, height 20 cm and a rim 1 cm wide for holding the outer pot in place. A plank, 10 cm long, 5 cm wide and 2 cm thick is used to stir the grain.

Evaluation of the equipment

The evaluation was conducted in January 2016. The most common maize variety in Zimbabwe which was in storage for approximately five months, with a visible natural infestion of predominantly P. truncatus (Horn) and S. zeamais (Motschulsky) (Coleoptera: Bostrichidae), the most common maize weevils in the country, was obtained from a communal farmer, 30 km north of Harare city. Sampling of maize was done following method in Giga and Mazarura (1990). The pre-trial weevil infestation level was determined by sampling about 2 kg of maize from each bag. The sample was then thoroughly mixed and a sub-sample of 250 g taken for insect identification. The sampling was done using a 2-metre bulk sampling probe which drew grain from four different levels vertically. The weevils were identified at the Department of Biological Sciences, University of Zimbabwe.

Maize from the three bags with a total weight of approximately 180 kg was poured onto a cement floor and thoroughly mixed using a shovel. Maize weighing 20 kg was poured into the inner pot (Figure 3). The pot was closed, carefully transferre to the outer pot (Figure 4) and inserted into the outer pot containing two litres of boiling water (Figure 5). The water was maintained at boiling point to the end of experiment. Maize cobs (with grain removed) and maize stalks were used as source of heat. The maize was stirred after every 5 min so that all the grain would come in contact with the bottom and lower sides of the inner pot which were the hottest parts and to allow homogeneous distribution of heat throughout the grain (Figure 6). In the first experiment, temperature was measured every five minutes to establish the relationship of temperature and time when the maize was exposed to heat from water which was constantly at boiling point. A Habor Digital Thermometer-Long Probe with Instant Read was used to measure the temperature. In the second experiment, temperature was measured at the beginning, at maximum insect activity and when activity was totally lost following guidelines from the first experiment. According to Chapman (1982) insects show a sharp rise in activity at the upper end of the preferred temperature range, and at still higher temperature, the activity is followed by an inability to move, a condition known as heat stupor and is followed by death of the insect.

At five minutes intervals, approximately 500 g of grain was taken out of the inner pot and carefully inspected for insect activity. At the same time, 20 damaged kernels were examined and insects dislodged using dissecting needles to determine status of the insects.. After treatment, the maize was exposed to open air for 20 min to allow cooling. The experiment was replicated three times.

Grain germination

The effect of heat on germination viability of the maize was evaluated by planting 100 uninfested seeds from each replicate treatment and untreated control. The seeds were planted in paper cups containing soil, placed in a greenhouse and watered daily until

germination.

Data analysis

Descriptive statistics were used to analyse data. The analysis was focused on mortality of insects and maize seed viability after exposure to heat form boiling water. Effect of heat on insect mortality was expressed as percentages of kernels containing dead insects at various temperature points. The χ2 test was used to

measure the difference in germination viability between heat treated and control grain.

Pre-trial maize damage assessment showed that more than half the experimental grain was infested. Results of three replicates from the first experiment showed no variation on effect of exposure to constantly boiling water on maize temperature and insect activity (Table 1). A sudden increase in insect mobility was observed at between 43 and 45°C, followed by attempts by the insects to escape In the second experiment, examination of 20 infested kernels from each replicate showed that the Zimba grain weevil killer achieved 100% mortality of adult P. truncutus and S. zeamais in maize grain following total loss of insect activity at ±48°C (when grain was just hot to the palm) (Table 2), achieved at 25 min post exposure to heat (Table 1). Maximum insect activity was observed when grain temperature was between 43 and 45°C (Table 1) attained between 22 and 25 minutes of grain exposure to heat (Table 1). Activity response to heat observed for both P. truncatus and S. zeamais was similar.

The present study described the Zimba grain weevil killer and the experiments conducted to evaluate the weevil killing efficacy of the equipment and assess germination viability of the heat treated grain. Many studies have been conducted in the past to evaluate heat treatment to disinfest grain using different types of equipment (Beckett et al., 2007). The equipment achieved 100% mortality of adult P. truncutus and S. zeamais in maize grain when the maize was exposed to a maximum temperature of 48°C (when grain was just hot to the palm) using heat from boiling water. The lethal temperature of 48°C observed in the present study is within the range reported in earlier studies (Beckett et al.. 2007). The heat treated grain showed germination viability of between 95 and 100% which was not significantly different from the control seeds.

Insect activity and mortality in the maize grain were monitored upto 48°C, a temperature at which there was total loss of adult insect activity. Immature stages were not monitored as they were reported to be more susceptible to heat than the adults (Chapman, 1982). Maximum insect activity was observed at a temperature of 43 to 45°C, reached after 20 min of grain exposure to heat from water kept constantly at boiling point. However, Yan et al. (2014) reported that heat tolerance in Sitophilus could vary with species. Prolonged exposure to a temperature of 43°C was reported to be lethal to S. zeamais (Lu and Zhang, 2016) and similarly S. oryzae exposed to a temperature range of 44 to 50°C for different time periods showed variations in mortality (Yan et al., 2014). Insect activity was totally lost when the grain temperature reached ±48°C, resulting in 100% insect mortality, observed at 25 min post exposure. These results support previous findings (Beckett et al., 1998; Evans, 1987) where stored grain pests R. dominica and S. oryzae were reported to have mortality thresholds of 42 to 48°C and 45 to 53°C respectively.

According to Fields and White (2002) heat treatment for insect pests is not new. In this study, heat from boiling water was exploited using a novel equipment to kill maize grain weevils. Extensive use of heat for fruit disinfestation, using both forced air and hot water has been reported (Hansen et al., 1992). Vapour heat has also been demonstrated as effective for disinfestation of cut flowers and foliage (Hansen et al., 1992). The use of radio frequency heating, both with and without additional heating (Janhang et al., 2005), has been evaluated for the treatment of insects in rice and nuts. In the present study, the killing equipment and the method of heat application and utilization to effect insect kill of the maize grain weevils could be new.

Different insect species have been reported to have different heat tolerance ranges. A study of desert Drosophila species (Stratman and Markow, 1998) showed greater tolerance of high temperature by some species, but was not consistent across all species and even the most tolerant conformed to the general rule of being within the 45 to 51°C. The loss of S. zeamais and P. truncatus activity observed at 48°C in the present study agrees with earlier reports of a 45 to 51°C heat tolerance range in many insect species.

Some studies have shown that insect mortality in grain can be achieved at lower grain temperatures but with longer exposure time which is also influenced by the moisture content of the grain (Beckett et al., 1998). The present study did not take into account the moisture content of the grain. However, the grain used in this study had been in storage for five months a period generally considered adequate for drying by local communities.. Beckett et al. (1998) studied the effects of both grain temperature and moisture content on the mortality of R. dominica and S. oryzae L. and concluded that the effects on insect mortality of grain moisture content within the range suitable for stored grain are small compared to the temperature effects. This tool is ideal for rural communities because firewood, maize cobs or dry maize stalks can be used as source of heat. The tool also uses very little water.

In the present study, maize grain was exposed to a maximum temperature of 48°C attained between 25 and 30 min of exposure to heat from boiling water. The viability results showed no significant differences in germination between treated and control grain. According to Akman (2009), prolonged dry heat treatment of 40°C for 72 h and 60°C for 24 h was reported to cause lower seed germination. The maximum exposure period of grain to heat was 30 min. It is possible that the high germination viability observed in the current study was due to the short exposure of grain to heat. As also reported earlier the extent of the loss of grain viability depends on the initial quality of the grain, the temperature and moisture content of the grain and the time of exposure. The maize grain used in this study was assured of good quality as it was obtained from a seasoned communal farmer and had been in storage for five months.

The current new tool disinfects maize grain by killing existing insects in a similar way as fumigants. The tool has the advantage that it can be used against insect pests which have become resistant to insecticides and there are no health hazards normally associated with direct chemical treatment The equipment has the potential for use in disinfesting stored grain insect pests infesting other grains such as sorghum, cow peas, beans and millet. The tool requires simple instructions. The tool costs USD60 and can be used over a number of years. Maize cobs (after removing the grains) and maize stalks can be used as a source of heat.

The author has not declared any conflict of interests.

REFERENCES

|

Akman Z (2009). Comparison of High Temperature Tolerance in Maize, Rice and Sorghum Seeds by Plant Growth Regulators. J. Anim. Vet. Adv. 8:358-361.

|

|

|

|

Beckett SJ, Fields PG, Subramanyam BH (2007). Disinfestation of stored products ans associated structures using heat. In: Tang J, Mitcham E, Wang S,Lurie S (Eds), Heat treatments for postharvest pest control: Theory and practice. CAB International 2007, Cromwell Press, Trowbridge, United Kingdom pp. 182-237.

Crossref

|

|

|

|

Beckett SJ, Morton R, Darby JA (1998). The mortality of Rhyzopertha dominica (F.) (Coleoptera:Bostrychidae) and Sitophilus oryzae (L.) (Coleoptera: Curculionidae) at moderate temperatures. J. Stored Prod. Res. 34:363-376.

Crossref

|

|

|

|

Benhalima H, Chaudhry MQ, Mills KA, Price NR (2004). Phosphine resistance in stored-product insects collected from various grain storage facilities in Morocco. J. Stored Prod. Res. 40:241-249.

Crossref

|

|

|

|

Boxall RA (2002). Damage and losses caused by larger grain borer Prostephanus truncatus. Integrated Pest Manag. Rev. 7:105-121.

Crossref

|

|

|

|

Charleston KF, Kfir R, Dickie M (2005). Impact of botanical pesticides derived from Melia azedarach and Azadirachtaa indica on the biology of two parasitoid species of the diamondback moth. Biol. Control 33:131-142.

Crossref

|

|

|

|

Chapman RF (1982). The Insects: Structure and Function (Eds Chapman RF) Hodder and Stoughton, Kent, England. 919pp.

View

|

|

|

|

Das I, Kumar G, Shah NG (2013). Microwave Heating as an Alternative Quarantine Method for Disinfestation of Stored Food Grains. Int. J. Food Sci. Article ID 926468, 13 p.

Crossref

|

|

|

|

Dent D (2000). Insect Pest Management, 2nd edition. CABI Publishing, Wallingford, 410 p.

Crossref

|

|

|

|

Evans DE (1987). Some biological and physical restraints to the use of heat and cold for disinfesting and preserving stored products. In Donnahaye E, Navarro S (Eds). Proceedings of 4th International Working Conference on Stored Product Protection, Tel Aviv, Israel, September 1986. pp. 149-164.

|

|

|

|

FAO (2016) Food losses and waste: a challenge to sustainable development.

View

|

|

|

|

Fields PG, White NDG (2002). Alternatives to methyl bromide treatments for stored product and quarantine insects. Annu. Rev. Entomol. 47:1-39.

Crossref

|

|

|

|

Giga DP, Mazarura UM (1990). Malathion resistance in Sitophilus zeamais (Motsch.) in Zimbabwe. Int. J. Pest Manage. 36:3-320.

|

|

|

|

Hansen JD, Hara AH, Tenbrink VL (1992). Vapour heat: a potential treatment to disinfest tropical cut flowers and foliage. HortScience 27(2):139-143.

|

|

|

|

Hill MG, Borgemeister C, Nansen C (2002). Ecological studies on the larger grain borer Prostephanus truncatus (Horn) (Coleoptera: Bostrichidae) and their importance for integrated pest management. Integrated Pest Manag. Rev. 7:201-221.

Crossref

|

|

|

|

Janhang P, Krihigamas N, Lucke W (2005). Using radio frequency heat treatment to control the insect Rhyzopertha dominica during storage in rice seed. Conference on International Agricultural Research for Development. Stuttgart-Hohenheim October, 2005 pp. 11-13.

|

|

|

|

Kasambala T, Chinwada P (2011). Modelling the occurrence of Prostephanus truncates (Coleoptera: Bostrichidae) in Southern Malawi. J. Stored Prod. Postharvest Res. 2(4):72-78.

|

|

|

|

Lü J, Zhang H (2016). The Effect of Acclimation to Sublethal Temperature on Subsequent Susceptibility of Sitophilus zeamais Mostchulsky (Coleoptera: Curculionidae) to High Temperatures.

Crossref

|

|

|

|

Mvumi BM, Stathers TE, Kaparadza V, Masiiwa P, Jowah P, Riwa W (2006). Comparative insecticidal efficacy of five of five raw diatomaceous earths against three tropical stored grain Coleopteran pests: Sitophilus zeamais, Rhyzopertha dominica and Tribolium castaneum. 9th International Working Conference on Stored Product Protection, Campinas, Brazil. pp. 868-876.

|

|

|

|

Nang'ayo FLO, Hill MG, Wright DJ (2002). Potential hosts of Prostephanus truncates (Coleoptera: Bostrichidae) among native and agro-forestry trees in Kenya. B. Entomol. Res. 92:499-506.

Crossref

|

|

|

|

Nyagwaya LDM, Mvumi BM, Saunyama IGM (2010). Occurrence and Distribution of Prostephanus truncatus (Horn) (Coleoptera: Bostrichidae) in Zimbabwe. Int. J. Trop. Insect Sci. 30 (4):221-231.

Crossref

|

|

|

|

Odeyemi OO, Masika P, Afolayan AJ (2008). A Review of the use of phytochemical for insect pest control. Afr. Plant Prot. 14:1-7.

|

|

|

|

Sori W, Ayana A (2012). Storage pests of maize and their status in Jimma Zone. Afr. J. Agric. Res. 7:4056-4060.

|

|

|

|

Stratman R, Markow TA (1998). Resistance to thermal stress in desert Drosophila. Funct. Ecol. 12(6):965-970.

Crossref

|

|

|

|

Tefera T (2012). Post-harvest losses in African maize in the face of increasing food shortage. Food Secur. 4:267-277.

Crossref

|

|

|

|

Upadhyay RK, Ahmad S (2011). Management Strategies for Control of Stored Grain Insect Pests in Farmer Stores and Public Ware Houses. World J. Agric. Sci. 7(5):527-549.

|

|

|

|

Yan R, Huang Z, Zhu H, Johnson JA, Wang S (2014). Thermal death kinetics of adult Sitophilus oryzae and effects of heating rate on thermotolerance. J. Stored Prod. Res. 59:231-236.

Crossref

|