Full Length Research Paper

ABSTRACT

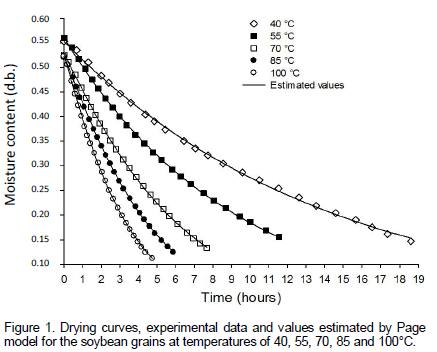

The aims of this work were to adjust different mathematical models to experimental data describing the drying of the Valiosa cultivar soybean grain, to determine and to evaluate the effective diffusion coefficient and to obtain the activation energy and the thermodynamic properties of the drying process under different air conditions. The Valiosa cultivar soybean grains, with an initial moisture content on a dry basis of 0.56 (d.b., decimal), were dried in an oven with forced air ventilation at five different temperatures (40, 55, 70, 85 and 100°C) until reaching a moisture content of 0.133 ± 0.019 (d.b.). Of the models analyzed, Page’s model was selected to best represent the drying phenomenon. The effective diffusion coefficient of soybeans increased with the air temperature and was described by the Arrhenius equation; an activation energy of 22.77 kJ mol-1 was reported for liquid diffusion in the drying of the soybeans. The enthalpy and entropy decreased with increasing temperature, while the Gibbs free energy increased with increasing drying temperature.

Key words: Glycine max, liquid diffusivity, enthalpy, entropy, Gibbs free energy.

INTRODUCTION

MATERIALS AND METHODS

where, RX: ratio of the moisture content of the product, dimensionless; X: moisture content of the product (d.b., decimal); Xi: initial moisture content of the (d.b., decimal); and Xe: equilibrium moisture content of the product (d.b., decimal).

where, Do: pre-exponential factor; Ea: activation energy, kJ mol-1; R: universal gas constant, 8.134 kJ kmol-1 K-1; and Tab:

absolute temperature, K.

The thermodynamic properties of the drying of soybean grains were obtained with the method reported by Jideani and Mpotokwana (2009):

RESULTS AND DISCUSSION

The average values of the moisture content ratio of the soybean grains dried under different air conditions are shown in Table 2. The times required for the grains to reach the moisture content of 0.133±0.019 (d.b.) were 18.6, 11.6, 7.7, 5.9 and 4.7 h for the drying temperatures 40, 55, 70, 85 and 100°C, respectively.

Thus, for the range of temperatures studied, the drying of soybean grains can be estimated using the following expression:

CONCLUSION

CONFLICT OF INTEREST

The authors have not declared any conflict of interest.

ACKNOWLEDGEMENTS

REFERENCES

| Almeida DP, Resende O, Costa LM, Mendes UC, Sales JF (2009). Cinética de secagem do feijão adzuki (Vigna angularis) [Drying kinetics of adzuki beans (Vigna angularis)]. Global Sci. Technol. 2:72-83. | ||||

| American Society of Agricutural Engineers (ASAE) (1988). Agricultural Engineers Handbook. ASAE, (35th), St. Joseph. Brasil, Ministério da Agricultura e Reforma Agrária. Secretaria Nacional de defesa Agropecuária (2009). Regras para Análise de Sementes [Regulations for Testing Seeds]. (1th ed.). Brasília. | ||||

| Brooker DB, Bakker-Arkema FW, Hall CW (1992). Drying and storage of grains and oilseeds. Westport: The AVI Publishing Company. P. 450. | ||||

| Carvalho PT (2012). Balanço de emissões de gases de efeito estufa de biodiesel produzido a partir de soja e dendê no Brasil [Balance of emissions of greenhouse gases from biodiesel produced from soybean oil and palm oil in Brazil]. Thesis (Master) presented to the the Graduate Program in Energy Planning, COPPE, Federal University of Rio de Janeiro. | ||||

| Corrêa PC, Araújo EF, Afonso Júnior PC (2003). Determinação dos parâmetros de secagem em camada delgada de sementes de milho doce (Zea mays L.) [Determination of the parameters related to thin-layer drying of sweet corn seeds (Zea mays L.)]. Rev. Bras. Milho Sorgo 2:110-119. | ||||

| Corrêa PC, Resende O, Goneli ALD, Botelho FM, Nogueira BL (2006). Determinação do coeficiente de difusão liquida dos grãos de feijão [Determination of the liquid diffusion coefficient of bean grains]. Rev. Bras. Produtos Agroindust. 8:117-126. | ||||

|

Corrêa PC, Oliveira GHH, Botelho FM, Goneli ALD, Carvalho FM (2010). Modelagem matemática e determinação das propriedades termodinâmicas do café (Coffea arábica L.) durante o processo de secagem [Mathematical modeling and determination of the thermodynamic properties of coffee (Coffea arabica L.) during the drying process]. Rev. Ceres 57:595-601. CrossRef |

||||

|

Corrêa PC, Botelho FM, Oliveira GHH, Goneli ALD, Resende O, Campos SC (2011). Mathematical modeling of the drying process of corn ears. Acta Scientiarum-Agronomy 33:575-581. CrossRef |

||||

| Costa LM, Resende O, Sousa KA, Gonçalves DN (2011). Coeficiente de difusão efetivo e modelagem matemática da secagem de sementes de crambe [Effective diffusion coefficient and mathematical modeling of the drying of crambe seeds]. Rev. Bras. Engenharia Agríc. Ambiental 15:1089-1096. CrossRef | ||||

|

Gely MC, Santalla EM (2007). Moisture diffusivity in quinoa (Chenopodium quinoa Willd.) seeds: Effect of air temperature and initial moisture content of seeds. J. Food Eng. 78:1029-1033. |

||||

| Goneli ALD, Corrêa PC, Afonso Júnior PC, Oliveira GHH (2009). Cinética de secagem dos grãos de café descascados em camada delgada [Kinetics of thin-layer drying of peeled coffee beans]. Revista Brasileira de Armazenamento special Coffe pp. 64-73. | ||||

|

Goneli ALD, Corrêa PC, Oliveira GHH, Botelho FM (2010). Water desorption and thermodynamic properties of okra seeds. Transactions of the ASAE 53:191-197. CrossRef |

||||

|

Henderson SM (1974). Progress in developing the thin layer drying equation. Transactions of the ASAE 17:1167-1168. CrossRef |

||||

| Henderson SM, Pabis S (1961). Grain drying theory: temperature effect on drying coefficient. J. Agric. Eng. Res. 6:169-174. | ||||

| Jideani VA, Mpotokwana SM (2009). Modeling of water absorption of botswana bambara varieties using Peleg's equation. J. Food Eng. 92:182–188. CrossRef | ||||

| Kassem AS (1998). Comparative studies on thin layer drying models for wheat. In: International Congress on Agricultural Engineering, 13th., Morocco. [Holdings]. Morocco: [s. n.]. P. 06. | ||||

|

Kitic D, Viollaz PE (1984). Comparison of drying kinetic of soybean in thin layer and fluidized beds. J. Food Technol. 19:399-408. CrossRef |

||||

|

Lewis WK (1921). The drying of solid materials. J. Ind. Eng. Chem. 13:427-433. CrossRef |

||||

|

Madamba PS, Driscoll RH, Buckle KA (1996). Thin-layer drying characteristics of garlic slices. J. Food Eng. 29:75-97. CrossRef |

||||

|

Midilli A, Kucuk H, Yapar Z (2002). A New model for single layer drying. Drying Technol. 20:1503-1513. CrossRef |

||||

| Mohapatra D, RAO PS (2005). A thin layer drying model of parboiled wheat. J. Food Eng. 66:513-518. CrossRef | ||||

| Mohsenin NN (1986). Physical properties of plant and animal materials. (1th ed.) New York: Gordon and Breach Publishers. | ||||

|

Nkolo Meze'e YN, Noah Ngamveng J, Bardet S (2008). Effect of enthalpy–entropy compensation during sorption of water vapour in tropical woods: the case of bubinga (Guibourtia Tessmanii J. L´Eonard; G. Pellegriniana J.L.). Thermochim. Acta 468:1-5. |

||||

| Oliveira DEC, Resende O, Smaniotto TAS, Campos RC, Chaves TH (2012). Cinética dos grãos de milho [Kinetics of corn grains]. Rev. Bras. Milho Sorgo 11:189-201. | ||||

|

Oliveira GHH, Corrêa PC, Araújo EF, Valente DSM, Botelho FM (2010). Desorption isotherms and thermodynamic properties of sweet corn cultivars (Zea mays L.). Int. J. Food Sci. Technol. 45:546-554. CrossRef |

||||

| Page GE (1949). Factors influencing the maximum rates of air drying shelled corn in thin layers. West Lafayette: Purdue University. | ||||

| Resende O, Corrêa PC, Goneli ALD, Botelho FM, Rodrigues S (2008). Modelagem matemática do processo de secagem de duas variedades de feijão (Phaseolus vulgaris L.) [Mathematical modeling of the drying process of two varieties of common bean (Phaseolus vulgaris L.)]. Rev. Bras. Prod. Agroind. 10:17-26. | ||||

| Resende O, Corrêa PC, Goneli ALD, Martinazzo AP, Ribeiro RM (2005). Contração volumétrica na difusão líquida durante o processo de secagem do arroz em casca [Volumetric contraction in liquid diffusion during the drying of paddy rice]. Rev. Bras. Armazenamento 30:163-171. | ||||

|

Sharaf-Eldeen YI, Blaisdell JL, Hamdy MY (1980). A model for ear corn drying. Transactions of the ASAE 23:1261-1265. CrossRef |

||||

| Siqueira VC, Resende O, Chaves TH (2012). Difusividade efetiva de grãos e frutos de pinhão-manso [Effective diffusivity of grains and fruits of Jatropha curcas]. Semina: Ciênc. Agrárias 33:2919-2930. CrossRef | ||||

|

Sousa KA, Resende O, Chaves TH, Moreira LC (2011). Cinética de secagem do nabo forrageiro (Raphanus sativus L.) [Drying kinetics of forage turnips (Raphanus sativus L.)]. Rev. Ciênc. Agron. 42:883-892. CrossRef |

||||

|

Thompson TL, Peart RM, Foster GH (1968). Mathematical simulation of corn drying: a new model. Transactions of ASAE 11:582-586. CrossRef |

||||

|

Verma LR, Bucklin RA, Endan JB, Wratten FT (1985). Effects of drying air parameters on rice drying models. Transactions of the ASAE 28:296-301. CrossRef |

||||

| Vernetti F de J, Vernetti Junior F de J (2009). Genética da Soja: Caracteres Qualitativos e Diversidade Genética [Soybean Genetics: Genetic Diversity and Qualitative Characteristics]. Embrapa Inform. Tecnológica, Brasília: DF. | ||||

|

Zogzas NP, Maroulis ZB, Marinos-Kouris D (1996). Moisture diffusivity data compilation in foodstuffs. Dry. Technol. 14:2225-2253. CrossRef |

||||

| Yagcioglu A, Degirmencioglu A, Cagatay F (1999). Drying characteristics of laurel leaves under different conditions. In: International Congress on Agricultural Mechanization and Energy, 7th., Adana. Proceedings. Adana: Cukurova University, pp. 565-569. | ||||

|

Wang CY, Singh RP (1978). Use of variable equilibrium moisture content in modeli |

||||

Copyright © 2024 Author(s) retain the copyright of this article.

This article is published under the terms of the Creative Commons Attribution License 4.0