Full Length Research Paper

ABSTRACT

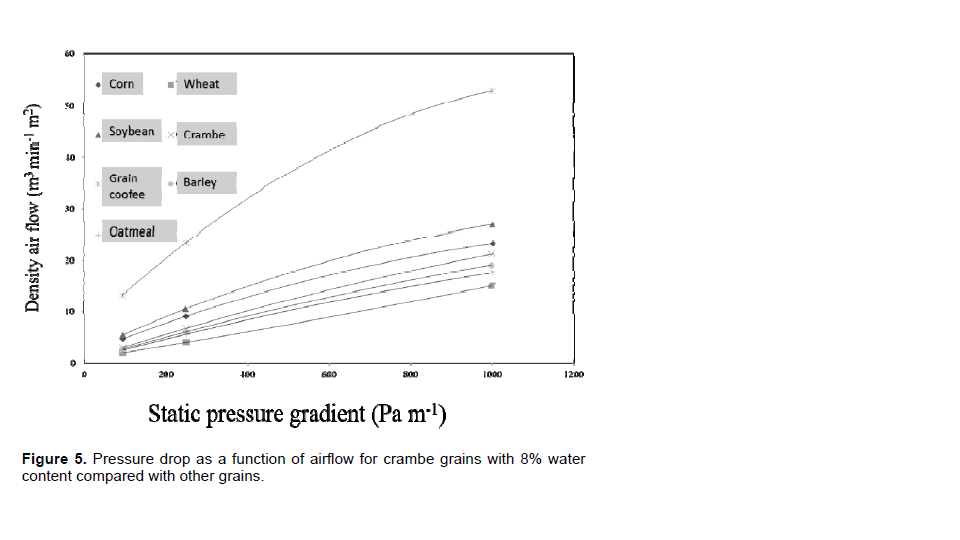

The crambe has emerged as an option for the production of biodiesel, constituting itself as an alternative for off-season grain in Brazil. To obtain the best performance in the post-harvest product processing, knowledge of physical characteristics of the grains to as well as of the design of machines and structure storage is necessary. After pre-cleaning, the crambe (Crambe abyssinica Hochst) with a water content of 8% (wb) was placed into a silo prototype, provided a fan and plenum, and subjected to five airflow densities that were pre-determined in a total of four repetitions for each tested airflow. The static pressure was measured through the column in five layers. The results show that there is a significant effect of air flow on the static air pressure in the crambe column, which increased linearly with depth. The experimental data fitted with good accuracy the models of Hunter and Shedd, thus enabling their use for the crambe column as well. The objectives of this study were to evaluate the variation of static pressure along a column of grains of crambe that were subjected to five airflow densities and check the fit of this variation following mathematical models suggested by Sheed and Hunter.

Key words: Crambe abyssinica, resistance to airflow, Sheed, Hunter.

INTRODUCTION

.png)

Where M and N represent the parameters of the fluid and the granular mass required for Ergun’s formulation (1952).

A large number of studies exist with regard to airflow resistance of cereals, oilseeds, and vegetables, but no information about the crambe that exhibits resistance to an airflow of 33 crops exists in the literature or is even compiled (ASAE, 2011).

This study aimed at evaluating the variation of the static pressure along a column of grains of crambe with 8% water content that was submitted to five airflow densities; it also aimed at checking the fit of this variation by following the mathematical models suggested by Sheed and Hunter.

MATERIALS AND METHODS

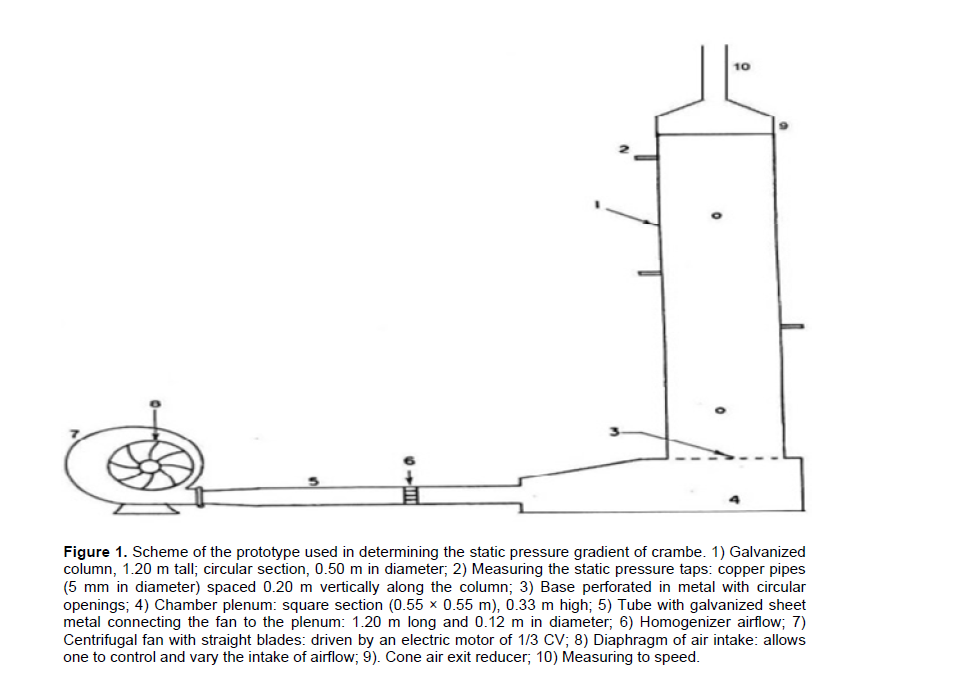

This study was conducted at the Universidade Estadual Paulista (UNESP), Faculty of Agricultural Sciences, Campus of Botucatu/São Paulo. Crambe grains with 8% water content after pre-cleaning were placed into a silo prototype characterized by a galvanized steel column (with five taken for measuring the static pressure), plenum, and fan (Figure 1).

Crambe grains were placed in free fall within the prototype, reaching a height of 1 m. The test consisted of static pressure measurements by using an inclined tube differential pressure gauge (18°), Dwyer brand; 0.5 mm precision of water column, at different depths, for each of the four repetitions, totaling twenty measures of depth in the column.

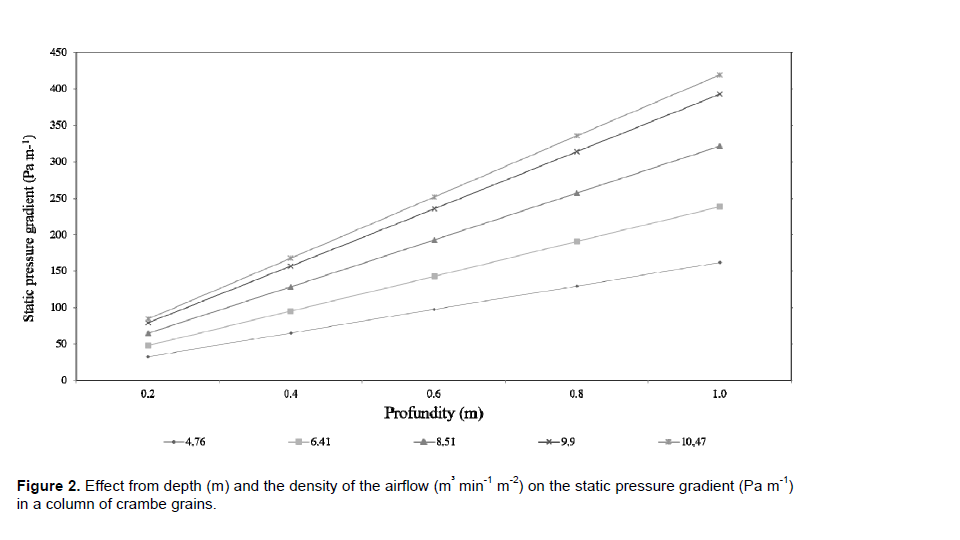

The densities of airflows used were as follows: 4.76, 6.41, 8.51, 9.90, and 10.47 m³min-1m-2. The experimental design was completely randomized, with five lots of crambe and four replications. After obtaining the results, the averages were submitted to an analysis of variance and means were compared by the “t” test (p ≤ 0.05).

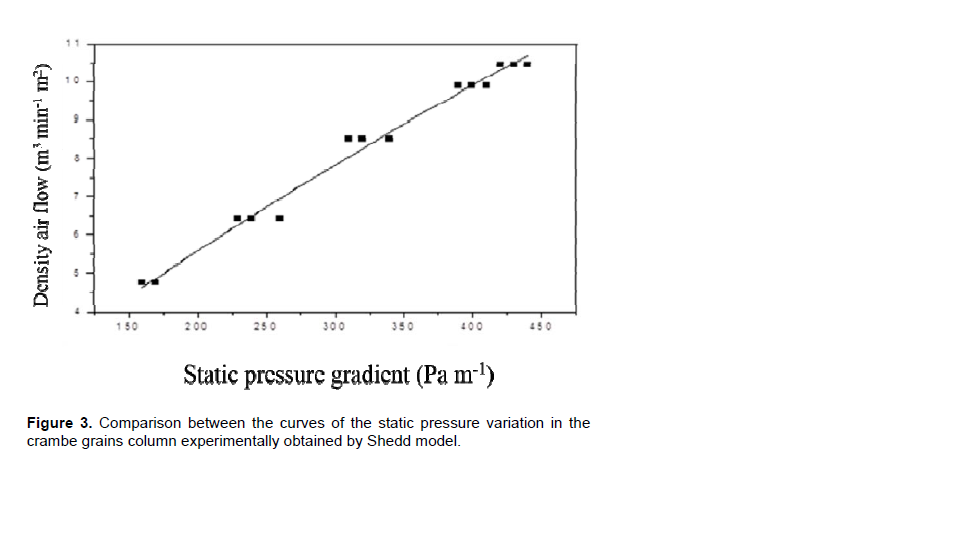

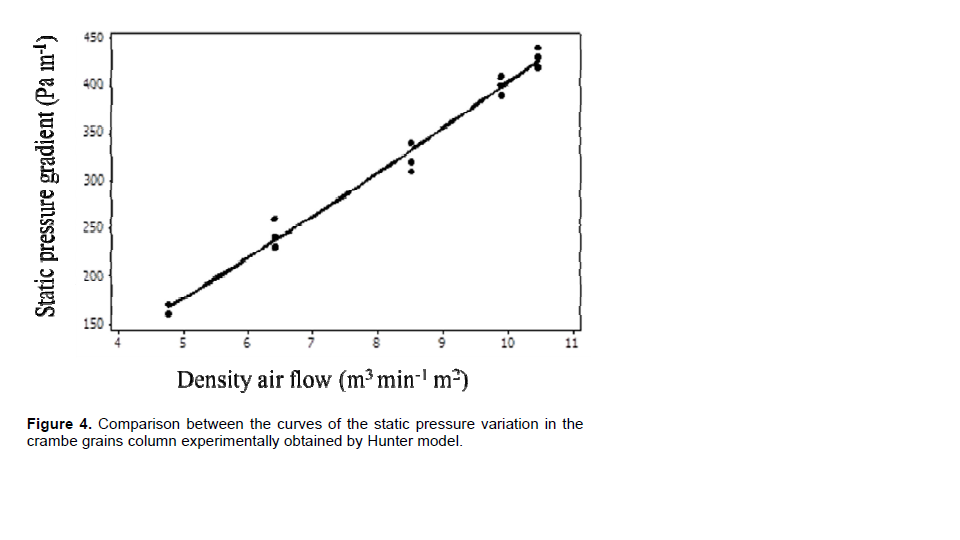

For adjusting the equations proposed by Sheed (1953) and Hunter (1983), the parameters a and b were used in Equation 1 and M and N were used in Equation 2. These parameters emerge from the specific physiological characteristics of each type of grain, and it is necessary to obtain these parameters by using simple linear regression analysis.

In the determination of the best adjustment, the coefficient of determination (R2) and the average percentage deviation (P) were used.

.png)

where P is the average deviation in percentage,%; n is the amount of experimental data; Ap exp is the pressure gradient values obtained experimentally, Pa m-1; and Ap calc is the pressure gradient values predicted by the model, Pa m -1.

RESULTS AND DISCUSSION

.png)

.png)

.png)

CONCLUSIONS

ACKNOWLEDGEMENTS

CONFLICT OF INTERESTS

The authors have not declared any conflict of interests.

REFERENCES

|

Abou-el-Hana NH, Younis MA (2008). Pressure drop through shelled corn as affected by airflow rates, moisture content and air temperature. Misr. J. Agric. Eng. 25(3):944-956. |

|

|

Agullo JO, Marenya MO (2005). Airflow Resistance of Parchment Arabica Coffee. Biosyst. Eng. 91(2):149-156. |

|

|

Amanlou Y, Zomorodian A (2011). Evaluation of air flow resistance across a green fig bed for selecting an appropriate pressure drop prediction equation. Food Bioproducts Process. 89:157-162. |

|

|

Andrade ET, Couto SM, Queiroz DM (2001). Distribuição da pressão estática em uma coluna de canola: análise por elementos finitos. Revista Brasileira de Engenharia Agrícola e Ambiental 5(2):288-295. |

|

|

ASAE D272. (R2011). Resistance to airflow of grains, seeds, other agricultural products, and perforated metal sheets. Am. Soc. Agric. Eng. pp. 1-7. |

|

|

Biaggioni MAM, Piza PLBT, Ferreira WA (2005). Queda de pressão estática por meio de uma coluna de noz de macadâmia. Engenharia Agrícola 25:499-507. |

|

|

Carneiro SMTPG, Romano E, Marianowski T, Oliveira JP, Garbim THS, Araújo PM (2009). Ocorrência de Alternaria brassicicola em crambe (Crambe abyssinica) no estado do Paraná. Comunicações. Summa Phytopathol. 35(2):154. |

|

|

Chun DS, Maghirang RG, Kim YS, Kim MS (2011). Effects of moisture and fine material on static pressure drops in a bed of grain sorghum and rough rice. Food Process Eng. Institute Am. Soc. Agric. Eng. 44(2):331-336. |

|

|

Ergun S (1952). Fluid flow through packed columns. Chem. Eng. Progress 48:89-94. |

|

|

Figueiredo NAF, Dantas BF, Silva JC, Olivier NC, Silva MF (2012). Resistência ao fluxo de ar das vagens de amendoim com diferentes percentuais de impurezas. Rev. Nucleus 9(1):85-91. |

|

|

Gratão PTS, Devilla IA, Servulo ACO, Jesus FF, Ferreira DA (2013). Perda de pressão estática em uma coluna de grãos de quinoa. Rev. Bras. Engenharia Agríc. Ambient. 17(8):848-854. |

|

|

Gonçalves DN, Resende O, Costa LM, Prado MC (2014). Determination of physical properties of crambe fruits during drying. Engenharia Agrícola 34(5):972-979. |

|

|

Hunter AJ (1983). Pressure difference across an aerated seed bulk for some common duct and store crosssections. J. Agric. Eng. Res. 28(5):437-450. |

|

|

Kashaninejad M, Tabil LG (2009). Resistance of Bulk Pistachio Nuts (Ohadi Variety) to Airflow. J. Food Eng. (90):104-109. |

|

|

Khatchatourian OA, Binelo MO (2008). Simulation of three-dimensional airflow in grain storage bins. Biosyst. Eng. 101:225-238. |

|

|

Khatchatourian OA, Toniazzo NA, Gortyshov YF (2009). Simulation of airflow in grain bulks under anisotropic conditions. Biosyst. Eng. 104:205-215. |

|

|

Lukaszuk J, Molenda M, Horabik J, Szot B, Montross MD (2008). Airflow resistance of wheat bedding as influenced by the filling method. Res. Agric. Eng. 54:50-57. |

|

|

Neethirajan S, Karunakaran C, Jayas DS, White NDG (2006). Xray computed tomography image analysis to explain the airflow resistance differences in grain bulks. Biosyst. Eng. 94(4):545-555. |

|

|

Oliva ACE, Biaggioni MAM, Cavariani C (2012). Efeito imediato do método de secagem na qualidade de sementes de crambe. Energia na Agricultura 27(3):16-30. |

|

|

Santos VP, Damasceno GS, Corrêa PC, Sinicio R(1999). Estudo da resistência ao fluxo de ar em uma camada de canola iciola-41 (Brassica napus L. var. oleifera). Engenharia Agrícola. 18(3):101-110. |

|

|

Silva MAP, Biaggioni MAM, Sperotto FCS, Bezerra PHS, Brandão FJB (2013). Qualidade do óleo bruto de grãos de crambe (Crambe Abyssinica Hochst) sob diferentes métodos de secagem. Energia Agric. 28(3):193-198. |

|

|

Silva MAP, Biaggioni MAM, Sperotto FCS, Puteri ACH, Saath R (2014). Influência do pericarpo no teste de condutividade elétrica em sementes de crambe (Crambe abyssinica Hochst) submetidas a métodos de secagem. Energia Agric. 29(4):301-305. |

|

|

Shedd CK (1953). Resistance of grains and seeds to airflow. Agric. Eng. 34(9):616-619. |

|

|

Shahbazi F (2011). Resistance of Bulk Chickpea Seeds to Airflow. J. Agric. Sci. Technol. 13:665-676. |

|

Copyright © 2024 Author(s) retain the copyright of this article.

This article is published under the terms of the Creative Commons Attribution License 4.0