ABSTRACT

In this study, chitosan-based coating was used in tangerines in a 30-day storage period, at controlled temperature of 10°C. The selected fruits presented green surface (± 90%); they were sanitized in chlorinated water (100 mg/L) then immersed in chitosan solutions at chitosan concentrations of 0.5 g/100 ml (T2), 1 g/100 ml (T3), and 2 g/100 ml (T4) and a lot was placed aside as control treatment (T1). Tangerines were evaluated in terms of loss of mass, skin color, soluble solids, vitamin C, and titratable acidity in a 30-day storage period and weight loss kinetics was evaluated through mathematical models. The results showed that chitosan coating was effective in delaying weight loss of tangerines and the mathematical models used in the evaluation could properly explain the weight loss. The polynomial model showed better adaptation to experimental data. Tangerines with higher chitosan concentration showed small color alteration during storage. Chitosan-based coatings were effective in keeping soluble solids, vitamin C, and titratable acidity during storage. In all physicochemical characteristics analyzed, chitosan-based coating in tangerines were superior when compared with control fruits.

Key words: Citrus, chitosan, postharvest, shelf life, quality.

Brazil is one of the largest citrus producers in the world, producing more than 128,000 tons a year (FAO, 2012). Citrus fruits are consumed all year long, in natura, or in the form of processed juice, compote and jelly (Rodrigo et al., 2013); however, they are perishable products and tend to postharvest degradation and reduced quality due to their physical aspects, such as loss of mass, and their chemical characteristics, like vitamin C (Mannheim and Soffer, 1996). The quality of citrus fruits is extremely important for marketing reasons, either for in natura consumption or industrial processing. The quality characteristics refer to citrus aspect, taste, smell, texture, and nutritive value. Recently, due to people’s increasing concern about human health and environmental protection issues, a growing interest has been seen in the development of biodegradable edible natural coatings to keep postharvest quality of fruits and vegetables (Arnon et al., 2014). In general, edible natural coatings comprised polysaccharides, proteins or lipids, or several compounds (Valencia-Chamorro et al., 2010; Dhall, 2013).

Amariz et al. (2010) and Silva et al. (2011) observed that edible coatings are an alternative to extend the shelf life of fruits and vegetables and they are nontoxic, preserve product quality, delaying deterioration, as they regulate metabolic activity, improving the appearance of stored fruits and ensuring brightness as an attractive factor for consumers.

Chitosan, a cationic polysaccharide of high molecular weight, obtained by deacetylation of chitin, extracted from the exoskeleton of crustaceans, fungi, and insects, and has innumerous agricultural and horticultural applications, due to its excellent ability to create an antimicrobial and antifungal film with biocompatibility, biodegradability and nontoxicity to human beings (Muzzarelli et al., 2012).

Chitosan creates a semipermeable film that regulates gas exchange, reducing transpiration, and consequently, ripening (Baustista-Baños et al., 2006). This coating has antimicrobial properties (Dutta et al., 2009) and studies showed that chitosan can control or delay postharvest deterioration of fruits and vegetables. Han et al. (2004) extend the shelf life of strawberries, Romanazzi et al. (2003) inhibited the deterioration of cherries with chitosan and Joas et al. (2005) delayed litchi pericarp browning.

Storing products at low temperatures is one of the main techniques used to extend the shelf life of fresh fruits and vegetables and reduce the decomposition and respiration processes (Zahid et al., 2013). Coatings combined with controlled temperature may extend the shelf life of fresh products, keeping the nutrition and sensory properties (Hancock et al., 2008; Cantin et al., 2011, 2012).

Based on the aforementioned considerations, the purpose of this study was to study the effect of different concentrations of chitosan on postharvest tangerines, associated with low storage temperature, to evaluate the physicochemical characteristics and the kinetic parameters of weight loss.

The study was conducted in the Fruit & Vegetable Laboratory from the Food Engineering Sector of the IFGoiano –Rio Verde Campus. The study used tangerines (Citrus deliciosa Tenore) of green surface (±90%) harvested manually in a rural property located in the region of Rio Verde – GO. The study was realized in May of 2014.

The fruits were rinsed with running water, satinized with a solution of sodium hypochlorite at 100 mg/L for 15 min and dried with hand tissue. Then, they were separated in four groups: tangerines without any coating (control treatment (T1)), tangerines coated with a chitosan solution at 0.5 g/100 ml (T2), tangerines coated with a chitosan solution at 1 g/100 ml (T3) and tangerines coated with a chitosan solution at 2 g/100 ml (T4).

Preparation of chitosan-based solutions

For preparation of the filmogenic solution, the following proportions of chitosan were used (formulation 1 L): 5 g (T2); 10 g (T3) and 20 g (T4). First, the chitosan was solubilized in glacial acetic acid and water, with pH adjusted to 4 with sodium 0.1 mol/L hydroxide, and 800 ml of distilled water and 50 ml of acetic acid. The formulations were homogenized in a blender for 30 s until chitosan gelation. After the preparation, the tangerines were immersed in different solutions (± 1 min) and placed on hollow metallic grilles until they dried naturally, creating chitosan biofilms.

Then, the fruits were placed on Styrofoam trays to be stored in BOD TECNAL TE – 371, at controlled temperature of 10 ± 0.1°C for 30 days, with analyses conducted every 10 days during the 30-day storage period.

Physical analysis

For the evaluation of physical characteristics of tangerines, the fruit dirt was eliminated with a hand tissue. Length (mm) and equatorial diameter (mm) were measured with a Digimess digital caliper. The (L/D) ratio (length/diameter) was calculated. Volume was determined with fruit immersion in a grade polypropylene jar with distilled water, by recording the amount of fluid displaced (ml). Fruit weight was determined using an analytical scale of three decimal places and the results were expressed in grams (g). A lot of 100 fruits were used to produce the physical analyses.

To determine the weight loss of tangerines, three repetitions were performed for every treatment and every repetition contained five fruits. Fruit weight was conducted with one CELTC FA 2104 Manalytical scale, with results expressed in grams. The same fruits were evaluated for weight loss during the 30-day storage period.

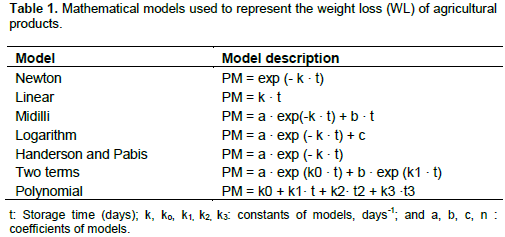

The experimental data of weight loss were adjusted to frequently used mathematical models to represent the water loss of tangerines (Table 1).

The colorimetric evaluation was conducted in a Hunter Lab colorimeter, Color Quest II model, in the Fruit & Vegetable Laboratory from the Food Engineering Sector of the IF Goiano –Rio Verde Campus (Hunterlab, 1998), and the values of luminosity L* index and chroma a* and b* indexes were recorded. The results were expressed in values L*, a* and b*, where L* (luminosity or brightness) values range from black (0) to white (100), a* values range from green (-60) to red (+60) and b* values range from blue (-60) to yellow (+60).

Chemical analysis

During storage, the tangerines were evaluated for the following chemical characteristics: total acidity was determined according to methodology n° 942.15 described by AOAC (1997), through titration with NaOH 0.1 M, and the results were expressed in g of total acid/100 ml; soluble solids were determined through direct reading in one Atago N-2 E refractometer, according to the methodology n° 983.17 described by AOAC (1999), and the results were expressed in brix; the vitamin C content was determined according to methodology n° 939.13 and 966.18 described by AOAC (1999), through titration with potassium iodide, and the results were expressed in mg of vitamin C/100 ml of juice.

Statistical analysis

The study used a completely randomized design, in a factorial scheme of 4 × 3 × 4, using four treatments (control – no chitosan coating; tangerines coated with chitosan at 0.5 g/100 ml; 1.0 g/100 ml and 2.0 g/100 ml), three temperatures (10, 20 and 30°C) and four storage times (0, 10, 20 and 30 days). The models were selected according to the coefficient of determination and its significance using the F test.

Kinetic data of weight loss were adjusted to mathematical models through a non-linear regression analysis using the Gauss-Newton method, with the help of statistical software. The models were selected considering the magnitude of the coefficient of determination (R2), chi-square test (c2) and standard error of the estimate (SE), according to Equations 5 and 6:

Where Y is the value observed in the experiment; Ŷ is the value estimated using the model; GLR is the degrees of freedom in the model (number of experimental observations minus the number of coefficients in the model).

Physical parameters

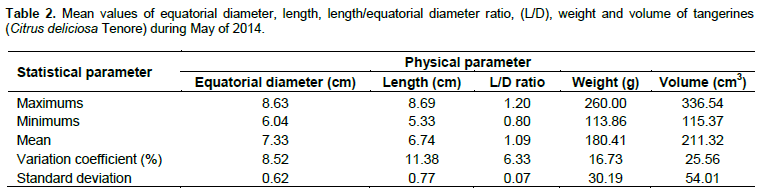

Table 2 shows the results of equatorial diameter, length, length/equatorial diameter ratio, weight and volume of tangerines.

The mean values of equatorial diameter and length of tangerines and the relation between these parameters showed the fruits presented a round shape. Tangerines (Citrus deliciosa Tenore) morphologically present a less pronounced peduncle, a characteristic of this type of fruit. Studies evaluating these physical parameters in tangerines have not been conducted. The mean weights of tangerines in this study were higher than the average weight of 212.86 g of Ponkan tangerine cultivated in Western Paraná (Detoni et al., 2009).

Kinetic parameters

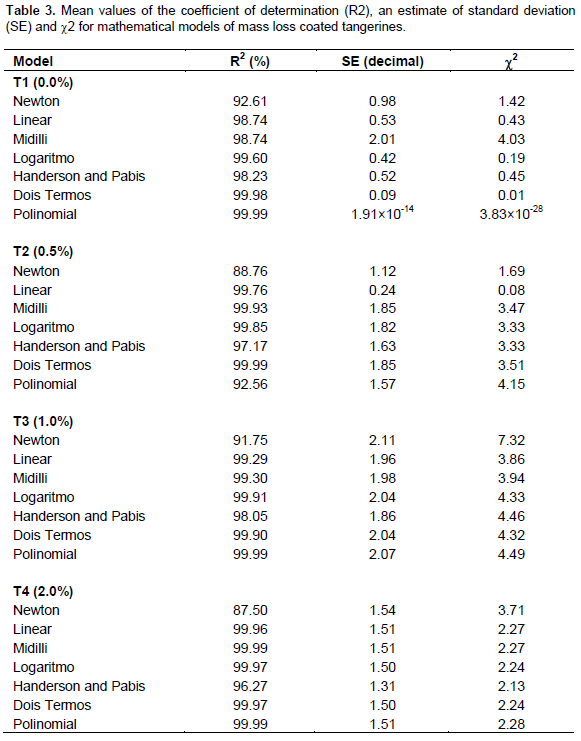

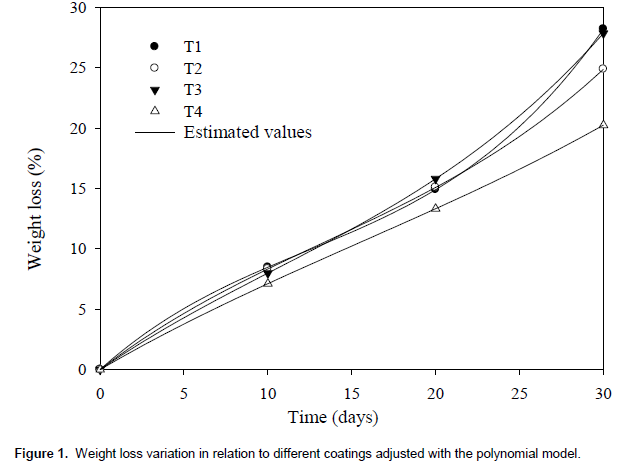

Table 3 shows the values of R2, SE, and c2. When analyzing coefficient determination R2, the polynomial model obtained the highest values for all treatments and the Newton model presented the lowest values. According to Doymaz (2012), calculating the coefficient of determination is one of the main criteria to select the model that better adjusts to the drying process; however, besides R², parameters SE and c² are used to determine the adjustment quality. Togrul and Aslan (2004), working with carboxymethylcellulose-coated tangerines, reported the polynomial model as the most suitable option to represent the weight loss of these fruits.

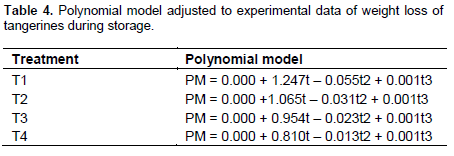

Table 4 shows the polynomial equations with constants obtained for the weight loss process of tangerines. Constant “k” is related to the water loss rate during storage processes, and the coatings, as a barrier against water loss, influenced “k” values. Data shows constant “k” is reduced in absolute values as chitosan concentrations increase in fruits, which is expected, as larger concentrations of coatings lead to lower water transfer to the environment.

Weight loss parameters

Figure 1 shows the behavior of weight loss along the storage time of tangerines coated with different chitosan concentrations, adjusted through the polynomial model. The weight loss analysis shows the coating was effective in delaying weight loss of tangerines. The positive effects of coatings on fruits include improved aspect and lower weight loss. Machado et al. (2012) report a highly significant interaction between coatings and storage time of fruits, reducing the weight loss of fruits. Shi et al. (2013), when evaluating the effect of coatings on postharvest longan fruits, confirm that coatings significantly reduce the weight loss of fruits.

The mathematical models describe weight loss in relation to storage time. The experimental data from this study are closely related to data estimated with the polynomial model, which indicates the model adequacy for the weight loss description of coated and non-coated fruits.

Mathematical models have not been widely used to explain the weight loss of fruits during storage, however, these models can efficiently explain the process and they may be used more frequently, as they present reliable results.

Color parameters

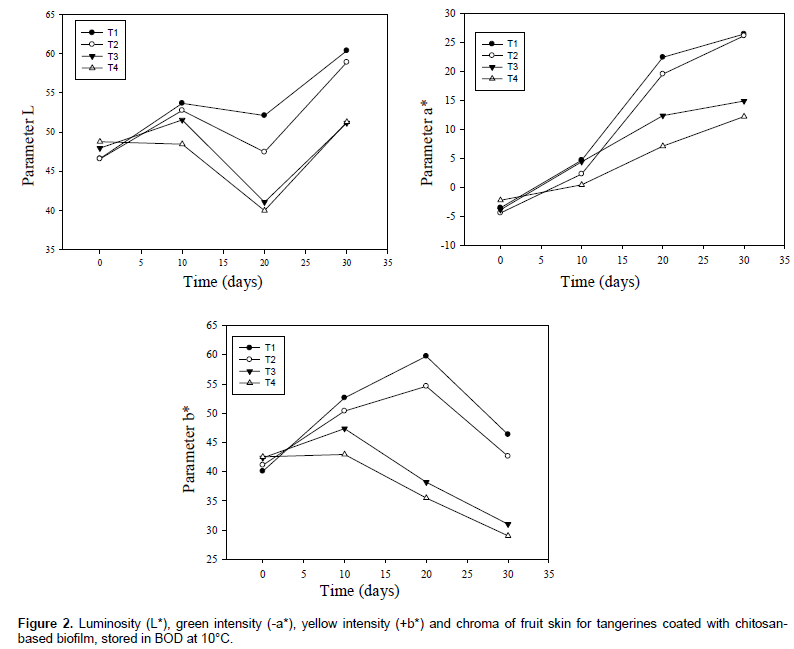

Color is one of the most influent attributes for consumers. Chlorophyll pigments are responsible for the green color of many fruits, including tangerines. When analyzing Figure 2, coatings caused small alteration to fruit color. On the first 10 days, the variations were small in all color parameters, increasing only after day 10.

Delay in color change may be attributed to low respiration and reduced ethylene, leading to a modified fruit atmosphere (Ali et al., 2011). Chitosan coating creates a semipermeable film, delaying ripening and senescence, and then, inhibiting color alteration (Han et al., 2014).

In the beginning of the storage period, the skin color of fruits was greener, and at the end of the storage period, the skin color was yellowish for the fruits with lower chitosan concentrations and control fruits, with increased parameter L for these fruits; therefore, increased luminosity is associated with yellow skin (Vale et al., 2006). The progress observed in b* values indicates the fruits indicated the coating can preserve fruit color for more time, inhibiting chlorophyll degradation. Likewise, the chitosan effect as a coating delayed color alterations in guavas (Hong et al., 2012).

Soluble solids parameters

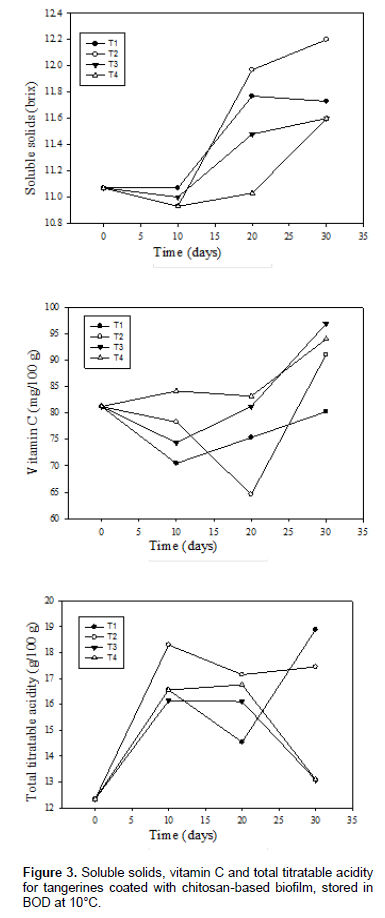

Figure 3 shows the alterations to the content of soluble solids, vitamin C and titratable acidity. In non-climacteric fruits, like tangerines, chemical variations are not very significant, as after the harvest, these fruits do not present considerable alterations, either in the content of soluble solids, vitamin C or acidity.

The content of soluble solids is an important internal quality parameter for fruits, and, according to data from this study, variations were not considerable in such parameter in all treatments, with a small increase along the storage period, indicating that coatings did not present significant influence. Holland (1998), when studying citrus tolerance to low temperatures, mentioned that a sugar buildup occurs in both juice and flavedo of the fruit, but sugar progress is distinct in both fruit parts; in juice, sucrose buildup is greater, while the contents of fructose and glucose are smaller.

According to Chitarra and Chitarra (2005), ascorbic acid is an antioxidant compound synthesized by fruits and vegetables in different quantities, according to the species, cultivar, environmental and nutritional factors and degree of maturation. Then, the level of vitamin C tends to fall as the fruit ripens, due to a direct action of ascorbic acid oxidase enzyme (ascorbinase), oxidation and consequent change of ascorbic acid into 2,3- dicetogulonicacid. In this study, the coatings led to increased content of vitamin C, possibly because the coating reduces the gas exchange rate with the environment, inhibiting the ascorbic acid exposure to O2 and concentrating it in the fruit. Han et al. (2014) reported delayed degradation of vitamin C in chitosan-coated luffa fruits (Luffa cylindrica).

Total titratable acidity parameters

Regarding total titratable acidity in fruits with chitosan concentrations of 1 g/100 ml and 2 g/100 ml, a reduction was observed in this parameter and in fruits with 0.5 g/100 ml and control fruits, an increase in acidity was seen. Scalon et al. (2012) explained the compounds responsible for acidity (organic acids) in fruits release hydrogen ions, contributing to increased acidity, and showing the senescence stage progress. However, in fruits with greater chitosan concentrations, peaks of acidity were observed between days 10 and 20, and reducing again to the initial level. This variation may be explained by the fruit variability; however, this tendency suggests delayed senescence of tangerines due to chitosan coatings.

Coatings are a simple and inexpensive way to significantly extend the shelf life of fruits. The mathematical models are effective in explaining the weight loss of fruits, with the coatings presenting a positive effect on delayed weight loss of fruits. Chitosan-based coating at the concentrations of 1 and 2 g/100 ml were efficient in delaying the yellow color of tangerines, which is the main indication of fruit ripening. Regarding the chemical parameters, coatings also ensured better maintenance in relation to soluble solids, vitamin C, and total titratable acidity, showing the positive effect of coatings.

The authors have not declared any conflict of interests.

The authors would like to thank FAPEG (Research Support Foundation of the State of Goiás) for the financial support to this project and CAPES (Coordination for the Improvement of Higher Level Personnel) for the postdoctoral fellowship granted to the second and fourth authors.

REFERENCES

|

Ali A, Muhammad MTM, Sijam K, Siddiqui Y (2011). Effect of chitosan coating son the physicochemical characteristics of Eksotika II papaya (Carica papaya L.) fruit during cold storage. Food Chem. 124:620-626.

Crossref

|

|

|

|

Amariz A, Lima MAC, Trindade DCG, Santos ACN, Ribeiro TP (2010). Coatings based on carboximethyl cellulose and dextrin in 'Tommy Atkins' mango fruit stored under refrigeration. Ciência Rural 40(10):199-205.

|

|

|

|

|

AOAC (1999). Official Methods of Analysis of the Association Analytical Chemists. 1999. 16th Edition, 5th Reversion, AOAC International, Gaithersburg, MD.

|

|

|

|

|

AOAC (1997). Official methods of analysis of the Association Analytical Chemists. 18.ed. Gaithersburg, Maryland.

|

|

|

|

|

Arnon H, Zaitsev Y, Porat R, Poverenov E (2014). Effects of carboxymethyl cellulose and chitosan bilayer edible coating on postharvest quality of citrus fruit. Postharv. Biol. Technol. 87:21-26.

Crossref

|

|

|

|

|

Bautista-Ba-os S, Hernández-Lauzardo AN, Velázques-del Valle MG, Hernández-López, M, Ait Barka E, Bosquez-Molina E, Wilson CL (2006). Chitosan as a potential natural compound to control pre and postharvest diseases of horticultural commodities. Crop Protection 25(2):108-118.

Crossref

|

|

|

|

|

Cantín CM, Minas IS, Goulas V, Jiménez M, Manganaris GA, Michailides TJ, Crisosto CH (2012). Sulfur dioxide fumigation alone or in combination with CO2-enriched atmosphere extends the market life of highbush blueberry fruit. Postharv. Biol. Technol. 67:84-91.

Crossref

|

|

|

|

|

Cantín CM, Palou L, Bremer V, Michailides TJ, Crisosto CH (2011). Evaluation of the use of sulfur dioxide to reduce postharvest losses on dark and green figs. Postharv. Biol. Technol. 59:150-158.

Crossref

|

|

|

|

|

Chitarra MIF, Chitarra AB (2005). Post-harvest of fruits and vegetables: physiology and handling. 2.ed. Lavras: UFLA. 785 p.

|

|

|

|

|

Detoni IAM, Herzog NFM, Ohland T, Kotz T, Clemente E (2009). Sun influence on the physical and chemical characteristics of 'Ponkan' tangerine cultivated in the west of Paraná state. Ciência e agrotecnologia 33(2):624-628.

Crossref

|

|

|

|

|

Dhall R (2013). Advances in edible coatings for fresh fruits and vegetables: a review. Crit. Rev. Food Sci. Nutr. 53:435-450.

Crossref

|

|

|

|

|

Doymaz I (2012). Evaluation of some thin-layer drying models of persimmon slices (Diospyros kaki L.). Journal Energy Conversion and Management, 56:199-205.

Crossref

|

|

|

|

|

Dutta PK, Tripathi S, Mehrotra GK, Dutta J (2009). Perspectives for chitosan based antimicrobial films in food applications. Food Chem. 114:1173.

Crossref

|

|

|

|

|

FAO (2012). Food and Agriculture Organization of the United Nations.

|

|

|

|

|

Han C, Zhao Y, Leonard SW, Traber MG (2004). Edible coatings to improve storability and enhance nutritional value of fresh and frozen strawberries (Fragaria × ananassa) and raspberries (Rubus ideaus). Postharvest Biology and Technology 33:67-78.

Crossref

|

|

|

|

|

Han C, Zuo J, Wang Q, Xu L, Zhai B, Wang Z, Dong H, Gao L (2014). Effects of chitosan coating on postharvest quality and shelf life of sponge gourd (Luffa cylindrica) during storage. Scientia Hortic. 166:1-8.

Crossref

|

|

|

|

|

Hancock J, Callow P, Serçe S, Hanson E, Beaudry R (2008). Effect of cultivar, controlled atmosphere storage, and fruit ripeness on the long-term storage of highbush blueberries. Hortic. Technol. 18:199-205.

|

|

|

|

|

Holland N (1998). Carbohydrate metabolism and tolerance of citrus fruits at low temperatures. PhD thesis - State University of Campinas. Faculty of Food Engineering 173 p.

|

|

|

|

|

Hong K, Xie J, Zhang L, Sun D, Gong D. (2012). Effects of chitosan coating onpostharvest life and quality of guava (Psidium guajava L.) fruit during cold storage. Acta Hortic. 144:172-178.

Crossref

|

|

|

|

|

Hunterlab (1998). User's manual with software versions 3.5, Reston. Instituto Adolf Lutz (1985). Analytical standards of Adolf Lutz Institute: v. 1, chemical and physical methods for analysis of food 3:393.

|

|

|

|

|

Joas J, Caro Y, Ducamp MN, Reynes M (2005). Postharvest control of pericarp browning of litchi fruit (Litchi chinensisSonn cv Kwaï Mi) by treatment with chitosan and organic acids I. Effect of pH and pericarp dehydration. Postharv. Biol. Technol. 38:128-136.

Crossref

|

|

|

|

|

Machado FLC, Costa JMC, Batista EN (2012). Application of carnauba-based wax maintains postharvest quality of 'Ortanique' tangor. Ciênc. Tecnol. Alimentos 32:261-266.

Crossref

|

|

|

|

|

Mannheim C, Soffer T (1996). Permeability of different wax coatings and their effect on citrus fruit quality. Food Chem. 44:919-923.

Crossref

|

|

|

|

|

Muzzarelli RAA, Boudrant J, Meyer D, Manno N, DeMarchis M, Paoletti MG (2012). Current views on fungal chitin/chitosan, human chitinases, food preservation, glucans, pectins and inulin: A tribute to Henri Braconnot, precursor of the carbohydrate polymers science on the chitin bicentennial. Carbohydr. Polymers 87(2):995-1012.

Crossref

|

|

|

|

|

Rodrigo MJ, Alquézar B, Alós E, Lado J, Zacarías L (2013). Biochemical bases and molecular regulation of pigmentation in the peel of Citrus fruit. Sci. Hortic. 163:46-62.

Crossref

|

|

|

|

|

Romanazzi G, Nigro F, Ippolito A (2003). Short hypobaric treatments potentiate the effect of chitosan in reducing storage decay of sweet cherries. Postharv. Biol. Technol. 29:73-80.

Crossref

|

|

|

|

|

Scalon SPQ, Oshiro AM, Dresch DM (2012). Postharvest conservation of guavira (Campomanesia Adamantium Camb.) under different coating and temperatures of storage. Rev. Bras. Frutic. 34:1022-1029.

Crossref

|

|

|

|

|

Shi S, Wang W, Liu L, Wu S, Wei Y, Li W (2013). Effect of chitosan/nano-silica coating on the physicochemical characteristics of longan fruit under ambient temperature. J. Food Eng. 118:125-131.

Crossref

|

|

|

|

|

Silva DFP, Siqueira DL, Santos D, Machado DLM, Salomão LCC (2011). Edible coatings on postharvest life of 'mexerica-do-rio'. Rev. Bras. Fru¬tic. 33:357-362.

|

|

|

|

|

Togrul H, Arslan N (2004). Carboxymethyl cellulose from sugar beet pulp cellulose as a hydrophilic polymer in coating of mandarin. J. Food Eng. 62:271-279.

Crossref

|

|

|

|

|

Vale AAS, Santos CD, Abreu CMP, Corrêa AD, Santos JA (2006). Chemical, physical and physical–chemical changes on tangerina 'ponkan' (Citrus reticulata Blanco) under refrigerated storage. Ciênc. Agrotecnol. 30:778-786.

|

|

|

|

|

Valencia-Chamorro S, Perez-Gago M, Del Rio M, Palou L (2010). Effect of antifungal hydroxypropyl methylcellulose-lipid edible composite coatings on Penicilliumdecay development and postharvest quality of cold-stored 'Ortanique' mandarins. J. Food Sci. 75:418-426.

Crossref

|

|

|

|

|

Zahid N, Ali A, Siddiqui Y, Maqbool M (2013). Efficacy of ethanolic extract of propolis in maintaining postharvest quality of dragon fruit during storage. Postharv. Biol. Technol. 79:69-72.

Crossref

|

|