ABSTRACT

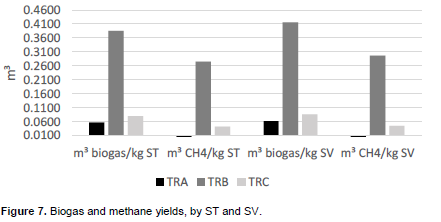

The purpose of this study was to evaluate the biogas production and the potential production obtained with the anaerobic digestion of cutting poultry carcasses. The carcasses were used to supply batch digesters with 8 liters of capacity of fermentation material. To perform this process, analysis content of total solids (TS) and volatile solids (VS) were performed. We used a system of three treatments, TRA (Treatment A) - 8% of ground chicken and 92% of water; TRB (Treatment B) - 8% of ground chicken, 20% of swine inoculum and 72% of water; TRC (Treatment C) - 13% of ground chicken, 20% of swine inoculum and 67% of water. The results were evaluated statistically showing that TRB treatment has shown better performance compared to the other two treatments, resulting in obtaining biogas at 0,3854 m³/kg TS and 0,4158 m³/kg VS, with an average production of methane (CH4) of 75.63%, thereby producing 0,2748 m³ of methane per kg of TS added and 0.2964 m³ of methan/kg VS-1 (???), with a hydraulic retention time (HRT) of 31 days.

Key words: Anaerobic, methane, environment.

The poultry industry has grown significantly in recent years, with its growth, there is also a need to produce increasingly higher quality. New management tech-nologies, increased population density of poultry and the short period between batches, are factors that directly influence the quality of the meat produced and on the resulting increase of waste (poultry litter, carcasses, waste water, etc.). According to UBABEF (2014), the poultry activity began in Brazil in 1950 and started to show rapid development. The Brazilian chicken meat production increased 48.62% in 13 years, reaching a production of 12.30 million tons in 2014. Currently, the country is the largest exporter of this product and also one of its largest consumers, with a 41.80 kg per capita consumption. Among the producing states, Paraná is the largest one, with a share of 31.12%, followed by Santa Catarina with 16.66% of total production. Still in the 50’s, Western Paraná has gone through massive changes since its colonization, due to modernization of national agriculture, replacing subsistence agriculture by the grain production. Brazil had several agricultural frontiers with expansion of grain production, in the Midwest, Northeast and North regions, taking also into account, places in the west mesoregion of Paraná State, which turned into a suitable region for the industries of slaughter and cattle, and poultry and swine meat processing (Dalmás et al., 2007).

In the West mesoregion of Parana, there are eight chicken slaughter houses, five cooperatives and three private companies, all of them exporting to other countries and distributing to the Brazilian domestic market (Belusso, 2010). According to IBGE (2015), Brazil slaughtered about 5.5 billion chicken carcasses in 2014. Abreu et al. (2009) mention that the poultry industry estimates approximately 3 to 5% mortality of birds during the process, causing a large environmental liability, together with the waste they had produced. The incorrect way to dispose of such carcasses, without prior treat-ment, can result in chemical and biological contamination of soil and water. Therefore, an alternative to mitigate environmental impasses generated by the improper disposal of poultry waste, would be the use of composting; however, many poultry farmers do not perform this procedure, thereby resulting in poor handling. Therefore, it is important to adopt a system of treatment of this waste in order to avoid possible environmental contamination (Güngör-Demirci and Demirer, 2004).

Bonturi and Dijk (2012) report that the biodigester is a biomass treatment system, to where the animal waste are conducted through pipes. This is where, through the anaerobic process, the bacteria that grow in total absence of oxygen causes the material to suffer a natural fermentation process and, at the end of the process, gases, pasty wastes and liquid effluents are produced. These by-products have economic value. The gas (methane) can be used in electric power generation, space heating, aviaries heating in winter and even in domestic stoves. The solid material turns into biofertilizer for farming, while the liquid effluents may be used for feeding algae in tanks that are then used as food for fish raised in ponds. Furthermore, according to Sánchez et al. (2001), the process of anaerobic digestion provides not only biogas, but also biofertilizer, which can replace conventional fertilizers when applied to various crops. This waste treatment in biodigesters also reduce pathogens and parasites, faecal coliforms and unpleasant odor, improving the environment of rural properties.

Without the presence of gaseous oxygen, anaerobic biodigestion is a decomposition process of organic matter by bacteria, divided into phases that together perform the decomposition of organic matter (Demirer and Chen, 2005). Initially, the liquefaction stage takes place, the organic matter is processed into dissolved compounds (volatile organic matter). In the following stage, the process is divided into two parts: acid fermentation and acetogenic fermentation. Even at this stage, the products of the previous subphase are transformed into acetate, hydrogen and carbon monoxide. In the third and final phase (methanogenesis), the acetogenesis products are transformed into methane in a greater proportion (Costa, 2006). According to Silva (2009), the anaerobic process takes places as follows: bacteria use the chemical components, such as carbon dioxide (CO2), nitrate (NO3), and sulfate (SO42-) to give the final product of oxidation of organic matter. This process consists of two stages. In the first one, the anaerobic and facultative bacteria process organic compounds of carbohydrates, lipids and proteins convert into volatile acids. In the second one, strictly anaerobic bacteria convert the volatile acids into gases such as methane and carbon dioxide, thus, resulting in biogas and in addition to contributing with the environment, it also generates income to producers.

China is one of the countries that mostly use biogas. They use it for cooking and home lighting in rural areas, including having their own biodigester model, with multiple working units installed (Nogueira and Zürn, 2005). In 1996, Brazil started studying the electric energy production using biogas and also in a more intensive way. The results achieved in Brazil are enough to demonstrate a good mastery of the biogas production technology, with competence and qualification to develop programs at the national level, both in rural and agro-industrial areas, as well as in urban and industrial areas (Seixas et al., 1980). At present, anaerobic digestion is the most widely used procedure in Brazil for the swine manure treatment, resulting in a large amount of gas, mainly composed of methane (CH4) (Oliveira et al., 2003). Salminen and Rintala (2002), performed a study on the potential for methane generation from the waste of poultry slaughter houses and demonstrated the importance of the use of this waste with potential: 0.20 to 0.25 m³ of CH4 kg-1 of poultry carcasses; 0.10 to 0.15 m³ of CH4 kg-1 poultry litter; 0.05 m³ of CH4 kg-1 of feathers; 0.10 m³ of CH4 kg-1 of blood, and 0.30 m³ of CH4 kg-1of viscera, feet and head. The objective of this experiment was to verify the technical feasibility of using anaerobic biodigestion to treat cutting poultry carcasses in order to take advantage of this by-product of poultry and adding value to it.

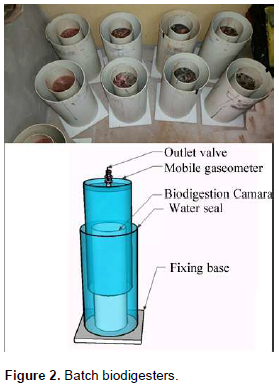

The experiment was conducted on a farm in São Miguel do Iguaçu - PR for a period of 102 days. The substrate for supplying the biodigesters was obtained in one of the aviaries of the farm where the experiment took place. A total of 22 chickens aged 21 days that were processed in an industrial crusher Siemsen brand, LSD-25 model was used. The grinding time was 30 s per bird, so that the resulting mass could stay on the desired consistency and be mixed for the experiment. After grinding, the whole mass was again mixed in a container, forming the substrate as shown in Figure 1. For the conduct and development of the research, 9 units of batch biodigesters were used, each with a total capacity of 8 L. This model was chosen because it is a most recommended system for treating waste which is removed less frequently, or in systems where the daily cleaning is not practiced.The batch biodigesters are composed of three distinct pairs, one of them being the container with the material in fermentation, the gasometer and the com-partment is to form the water-seal. The container with material in fermentation was composed of a Polyvinyl Chloride (PVC) straight cylinder, measuring 150 mm in diameter and 480 mm in height. The gasometer consisted of a PVC straight cylinder with 480 mm diameter by 200 mm height, having one end closed by a valve that either allows or not the passage of gas for analysis and burning. The water-seal compartment was formed by a PVC straight cylinder with 250 mm diameter and 480 mm height. The biodigesters were located at room temperature in a masonry room with an area of 4 square meters, as shown in Figure 2.

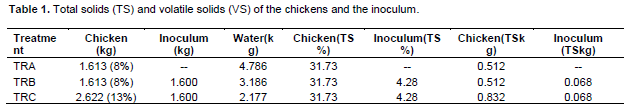

The treatments were performed in triplicate and formed as follows: TRA - 8% ground chicken, and 92% water; TRB - 8% ground chicken, pig inoculum 20% and 72% of water; TRC - 13% ground chicken, pork 20% inoculum and 67% water. All treatments were performed in triplicate. According to Assis (2004), in his study with some models of digesters, the fact that the gasometer be willing or on the substrate or on the water seal reduces losses during the biogas production process, the author had reported that the substrate used for feeding these models digesters must present a concentration inoculum equal to 20% and a total solids (TS) of not more than 8% to improve the circulation of substrate through the chamber from fermentation thus, avoiding blockages in their inlet and outlet pipes. After preparing the substrate, the characterization was conducted, in order to know the VS and TS levels for the chickens and inoculum samples, according to the methodology described by (APHA, 2012). For the determination of TS, the samples were placed in previously tared and weighed porcelain crucibles, in order to obtain the wet material and, after that, they were placed in an oven with air forced circulation at a temperature of 105°C, until reaching constant weight; then, they were cooled and reweighed, as a means to know the dry material weight. In order to determine the VS, the resulting dry material was placed in the muffle furnace and kept at a temperature of 575°C for 30 min. After cooling, the resulting material was weighed, for the purpose of having the mineral matter weight. The standardization values of the treatments are presented in Table 1. In order to obtain the substrate weight which should be added to represent the desired percentage of TS, the following equations were used:

Pst is Total Solid Weight (kg), Mt is the mixture total mass of the biodigester (kg), Sub is the added substrate percentage (%), Psa is the added substrate weight (kg) and Ps is the solid weight of wet substrate 1 kg (kg).

After calculating the quantities in Table 1, the mixture was mixed, according to the composition of each treatment, resulting in a total weight of 6.400 g for each treatment, which equals 80% of the biodigester capacity. The water used was collected in an artesian well at the site of the experiment. H is Ph value measured at 7, with a Schott Gerate CG818 model equipment. The inoculum was collected at the outlet of a biodigester in a swine farm in São Miguel do Iguaçu - PR. The substrate, inoculum and water were properly weighed, added in the biodigesters and mixed thoroughly. After this process, the biodigesters were closed with the gasometer, and water was added to form the seal. The biodigesters were subjected to daily readings gauge pressure, gasometer displacement and room temperature. The gauge pressure in cm H2O was measured by a water column gauge, constructed by the authors. The gasometer displacement readings in cm was measured by a ruler attached to the gasometer itself. The temperature was measured by a TagTemp model Novus thermometer. After performing the readings, the generated gas was burned.

Weekly, the gas was collected and taken to the laboratory of the Federal University of Technology - Parana, Medianeira campus, to perform chromatography, in order to know the generated gas percentage. The chromatograph used was Clarus 680 model Perkin Elmer with Elite-Plot Q column, 30 m in length and internal diameter of 0.32 mm. To perform the sample collection, it was used with glass syringes of 60 ml capacity with metallic needles. A rubber hose was attached to the outlet valve of the gas meter, the valve was opened for the passage of gas and allow the exit of possible impurities contained in the hose. The end of the hose was closed with a catch and the needle was inserted to the suction gas which was made. After removing the needle, the same was immediately closed with a protective cover to prevent leaks and the air intake. For each case, treatment was collecting up 3 samples, they were stored in a cooler and transported to the laboratory. The collection time until arrival at the laboratory was 30 min. In the 102nd day, having noticed that the daily production was already very low, the biodigesters were opened and the waste was discarded in the composting home of the experiment aviary. The correction of the biogas volume, for the conditions of 1 atm and 20°C, was made based on the Caetano (1985) work as equation 3. For correction of biogas volume, the average gauge pressure considered in this period was 9810 mm.

Where: Po = Pressure at STP (760 mmHg), Vo = Volume at STP, To = Temperature at STP (293K), P1 = Local pressure in São Miguel do Iguaçu (981.03 mmHg), V1 = Measured volume (L), T1 = Measured temperature (K).

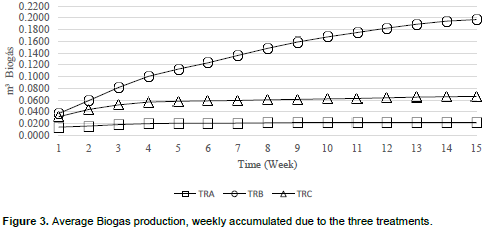

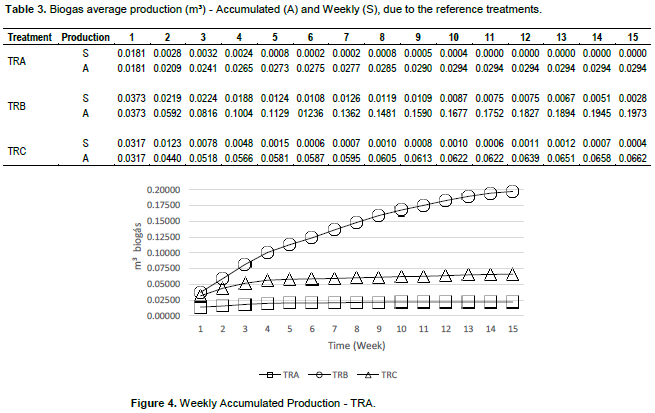

After the characterization to get the moisture, TS and VS percentage, the sample had shown moisture 68.27%, with TS of 31.73% and, from this last percentage, VS of 29.41%. Under Brazilian table of food composition TACO (2011), the whole raw chicken moisture, with skin, reaches 66.5%. Guimarães and Adell (1995) and Ordóñez (2005) report that the chicken muscle contains the average of about 75% water of its weight. The muscle is the main component of the meat. As the animal organism, it contains water, proteins, fat, carbohydrates and inorganic constituents. The amounts of substrates added in the biodigesters were calculated from equation 1 and equation 2. Considering 8% substrate, we have Pst = 0.512 kg and Psa = 1.613 kg. Considering 13% of substrate, we have Pst = 0.832 kg and Psa = 2.622 kg. The experiment results showed biogas production data in the form of weekly and total accumulations as shown in Figure 3. We can see that TRB presented a higher production level than the other treatments, reaching 0.197 m³ of biogas accumulated in 15 weeks, against 0.069 m³ of TRC and 0.022 m³ of TRA. It is remarkable that TRA and TRB began to accumulate less at the end of the 12th week, while TRA had stabilized in the 7th week.

According to Steil (2001), in the anaerobic digestion system, a number of factors can have some influences, depending on the favor (or not favor) of the process starting. The substrate degradation, the growth and decline of the microorganisms involved, biogas production, anyone can determine the success or failure of the treatment of a particular waste. Among such factors, we can mention the pH, the presence of nutrients in the substrate composition, the total solids content and temperature, and as a consequence thereof, the interaction among the microorganisms involved in the process. The effect of temperature is one of the most important factors in the anaerobic digestion, since it acts on the speed of the bacterial metabolism, in the ionic equilibrium of substrates and their solubility (Foresti et al., 1999). The substrate pH and alkalinity were not observed either before or after the process, but due to the premature reduction of biogas production and to the characteristics of the added organic matter, it appears that the material suffered acidification, thereby inhibiting the TRA and TRB treatments production.

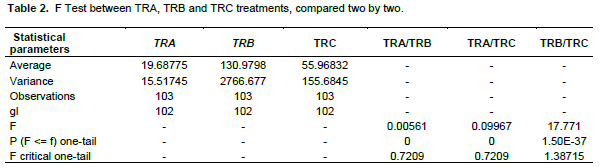

Hobson and Wheatley (1993) stated that one of the main reasons of a biodigester failure can occur at the beginning of the process, because the methanogenic flora which generally takes more time to be reduced than the acidogenic one, can not metabolize all produced organic acid, causing pH reduction. Low pH values inhibit methanogenesis and its production tends to get worse. Thus, input organic loads prevent the formation of large amounts of acids. Table 2 represents the weekly accumulated biogas production for three treatments. By statistically analyzing the three treatments production by F test, and comparing the samples two by two, all of them were significantly different from each other, with a 5% significance. Table 3 represents the biogas average production accumulated and weekly due to the reference treatments. When comparing TRB with TRC, we can verify that, at the end of the 15th week, TRB and TRC accumulated 0.1973 m³ and 0.0662 m³, respectively, thereby having TRB a greater biogas production, that is, 0.1311 m³. This difference is probably due to the fact that TRC contains more 5% of substrate. According to Mazzucchi (1980), it is necessary that the concentration of dry matter ranges from 7 to 9%, to be considered a satisfatory methane production. Figure 4 shows the cumulative biogas production monthly. It is observed, that the TRB treatment showed higher production compared to the other treatments.

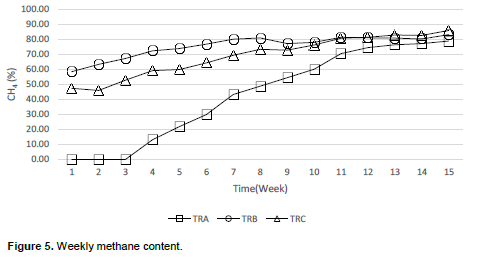

In figure 4, the biogas methane content data are weekly measured during the development of the experiment. Among the data, we can see that, in the 3rd week, the gas produced had methane contents above 50%, with the sole exception of that one produced by TRA treatment that had not yet recorded considerable rates of methane. From the 11th week, all substrates produced biogas with methane content above 70%, and the TRB treatment had methane content above 65% in the 3rd week. According to Seixas et al. (1980), since the microorganisms specifications and quality of life are met, the biogas generated will compose a gas mixture, with methane contents of about 60 or 65% of the total volume. The remaing content is made up of 35 or 40%, mainly carbon dioxide, and also smaller amounts of other gases. This biogas composition may vary, according to the type and quantity of the used biomass, as well as to climatic factors and to the biodigester dimensions, among others. Figure 5 represents the average of methane levels found among triplicates for each treatment, showing that the TRB treatments and TRC contained methane in its composition at the beginning of the 2nd week as the TRA treatment presented behavior similar to the other treatments, in the middle of the 9th week.

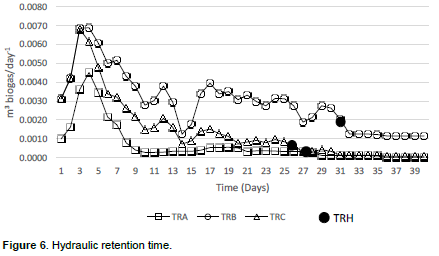

When analyzing the TRA treatment with the TRB and TRC ones, we can see that the TRA methane production began at week 4 and had a low methane percentage, however, in the other treatments, the production began in the 1st week and had a high percentage of methane. This occurred due to the fact that TRB and TRC treatments have had inoculum in its composition, which accelerated the process. The purpose of analyzing non-inoculum TRA was precisely to know the substrate characteristics in natural situations. The obtained HRT (Hydraulic Retention Time) for each treatment was based on the percentage of the daily volume of biogas produced, according to the accumulated total volume. A production that showed a daily amount greater than 1%, in relation to the total accumulated volume, was considered acceptable. According to VDI (2006), when the daily production is less than 1% of the total accumulated biogas produced, we can consider it as the end of the production, since the production volume is no longer satisfactory. According to figure 6, the TRA treatment presented HRT of 27 days, TRB presented HRT of 31 days and TRC, 26 days.

The result of the biogas production is presented in a weekly and cumulative format, as shown in Table 3. From these data, we can see that the TRB and TRC treatments had cumulative production greater than TRA; we can also highlight that, at the end of the studied period, TRB had a much higher production than the others. In a general way, the period of maximum production of both treatments occurred in the first week, while the treatment that remained stable further until the 9th week was the TRB one, as TRC has started to decline at week 3. Moller et al. (2004) studied the ways of separating solid fractions of swine effluents and found production potentials of 0.210 m³ CH4/kg VS to solid fraction of the waste resulting from centrifugation, 0.247 m³ CH4/kg VS to solid fraction of the waste resulting from chemical precipitation and 0.506 m³ CH4/kg VS for the liquid fraction of the waste resulting from centrifugation. In the Figure 7, we have the biogas and methane yields, by ST and SV. We can verify that TRB was superior in all results, reaching an average production of 0.4158 m³ biogas/kg SV and 0.3144 m³ methane/kg SV. According to Baldin (2013), the cutting poultry waste, in solid state, have a biogas production of about 0.36 m3/kg, in dry matter; secondly, we have the swine waste, in liquid state, presenting 0,35 m3/kg, and thirdly, we have livestock waste, with 0.30 m3/kg.

We can observe that the TRB treatment was the one that presented the best results, both in the biogas production and in the amount of methane produced. The inoculum showed a good result for the production acceleration, showing that it can be used in future researches. The TRA treatment produced a good amount of biogas in the early stage of this study, but had its process practically reduced in the third week. The TRC treatment, with 5% more substrate than TRB, did not present an adequate result, thus, proving that 8% of substrate produces biogas in a satisfactory manner. Thus, it could be concluded that biogas production is feasible, when using cutting poultry by batch process, using 8% substrate, 20% swine inoculum and water. TRB showed that the ground cutting poultry waste gave 0.385 m³/kg TS, showing that this waste can present a great potential for various forms of energy. Testing the biodigestion with 6 and 4% of substrate concentration, in two treatments, is a suggestion for further researches, as well as using 30% inoculum in other treatment, in order to know whether the method used in this study, was actually efficient.

The authors have not declared any conflict of interests.

REFERENCES

|

Abreu VMN, Pedroso-de-Paiva D, Abreu PG, Coldebella A (2009). Desempenho da casca de arroz e da palhada de soja na decomposição de carcaças de frangos de corte. In: I Simpósio Internacional sobre Gerenciamento de Resíduos de Animais (SIGERA). Florianópolis, SC.

|

|

|

|

APHA (American Public Health Association) (2012). Standard methods for the examination of water and wastewater. 22nd ed. Washington.

|

|

|

|

|

Assis FO (2004). Bacia hidrográfica do Rio Quilombo: dejetos de suínos e impactos ambientais. Curitiba: Ed. UFPR.

View.

|

|

|

|

|

Baldin V (2013). Geração de energia na avicultura de corte a partir da cama de aviário. Dissertação apresentada ao Programa de Pós-Graduação em Engenharia Elétrica da Universidade Tecnológica Federal do Paraná. Pato Branco 2013.

|

|

|

|

|

Belusso D (2010). A evolução da avicultura industrial brasileira e seus efeitos territoriais. Revista Percurso - NEMO Maringá 2(1):25-51.

View.

|

|

|

|

|

Bonturi GL, Dijk MV (2012). Instalação de biodigestores em pequenas propriedades rurais: análise de vantagens socioambientais. Revista Ciências do Ambiente On-Line. Outubro 8(2):88-95.

|

|

|

|

|

Caetano L (1985). Proposição de um sistema modificado para quantificação de biogás. 1985. 75 f. Dissertação (Mestrado em Energia na Agricultura) - Universidade Estadual Paulista, Faculdade de Ciências Agronômicas, Botucatu.

|

|

|

|

|

Costa DF (2006). Geração de Energia Elétrica a Partir do Biogás do Tratamento de Esgoto. Dissertação (Mestrado em Energia) – Universidade de São Paulo – USP, São Paulo.

|

|

|

|

|

Dalmás SRS, Staduto JAR, Willers EM (2007). Da Fronteira agrícola a fronteira agroindustrial: Uma análise da concentração das empresas de abate e de processamento da carne de frango no oeste do Paraná" Ano IX Nº 16 Dezembro de 2007 Salvador, BA 49.

View

|

|

|

|

|

Demirer GN, Chen S (2005). Two-phase anaerobic digestion of unscreened dairy manure. Process Biochem. 40(4):3542-3549.

Crossref

|

|

|

|

|

Foresti E, Florêncio L,Van Haandel A, Zaiat M, Cavalcanti PFF (1999). Fundamentos do tratamento anaeróbio. In: CAMPOS, J. R. (Coord.). Tratamento de esgotossanitários por processo anaeróbio e disposição controlada no solo. Rio de Janeiro: ABES. Cap. 2:29-52.

|

|

|

|

|

Guimarães JL, Adell EAA (1995). Estrutura e bioquímica do músculo. Apostila do Laboratório de Carnes. DTA-FEA-UNICAMP.

|

|

|

|

|

Güngör-Demirci G, Demirer GN (2004). Effect of initial COD concentration, nutrient addition, temperature and microbial acclimation on anaerobic treatability of broiler and cattle manure. Bioresour. Bioprocess 93(2):109-117.

Crossref

|

|

|

|

|

Hobson PN, Wheatley AD (1993). Anaerobic digestion: Modern theory and practice. Londres: Elsevier Appl. Sci. 269 p.

|

|

|

|

|

IBGE (2015). Instituto Brasileiro de Geografia e Estatística.

|

|

|

|

|

Mazzucchi OAJ (1980). Biodigestor. rural. São Paulo, CESP. 29 p.

|

|

|

|

|

Moller HB, Sommer SG, Ahring BK (2004). Methane productivity of manure, straw and solid fractions of manure. Biomass Bioenergy 26(5):485-495.

Crossref

|

|

|

|

|

Nogueira CEC, Zürn HH (2005). Modelo de dimensionamento otimizado para sistemas energéticos renováveis em ambientes rurais. Eng. Agríc. Jabot. 25(2):341-348.

|

|

|

|

|

Oliveira PD, Higarashi MM, Nunes MLA (2003). Efeito estufa: emissão de gases, na suinocultura, que provocam o efeito estufa. Suinocultura Industrial, São Paulo 25(7):16-20.

|

|

|

|

|

Ordó-ez JA (2005). Tecnologia de alimentos: componentes dos alimentos e processos. Tradução Fátima Murad. Porto Alegre: Artimed 1:294.

|

|

|

|

|

Salminen EA, Rintala JA (2002). Semi-continous anaerobic digestion of solid poultry slanghterhouse waste: effect of hydraulic retention time and loading. Water Res. 36(13):3175-3182.

Crossref

|

|

|

|

|

Sánchez E, Borja R, Weiland P, Travieso L, Martín A (2001). Effect of substrate concentration and temperature on the anaerobic digestion of piggery waste in a tropical climate. Process Biochem. 37:483-489.

Crossref

|

|

|

|

|

Seixas J, Folle S, Machetti D (1980). Construção e funcionamento de biodigestores. Brasília, DF: EMBRAPA, DID, Circular técnica 4, 60 p.

|

|

|

|

|

Silva WR (2009). Estudo Cinético do Processo de Digestão Anaeróbica de Resíduos Sólidos Vegetais. Tese (Doutorado em Química Analítica) - Universidade Federal da Paraíba, João Pessoa, Brasil.

|

|

|

|

|

Steil L (2001). Avaliação do uso de inóculos na biodigestão anaeróbia de resíduos de aves de postura, frangos de corte e suínos. Dissertação apresentada ao Instituto de Química do Campus de Araraquara – UNESP, para obtenção do título de Mestre em Biotecnologia – Área de concentração em Biotecnologia. Araraquara – SP.

|

|

|

|

|

TACO (Tabela brasileira de composição de alimentos) (2011). NEPA – UNICAMP, 4ª edição rev. E ampl. Campinas – SP.

|

|

|

|

|

UBABEF (União Brasileira de Avicultura) (2014). Relatório anual 2014.

View

|

|

|

|

|

VDI (Verein Deutscher Ingenieure) (2006). VDI 4630: Fermentation of organic materials – Characterisation of the substrate, sampling, collection of material data, fermentation tests. In VereinDeutscherIngenieure (VDI) (Ed.), VDI HandbuchEnergietechnik. Berlin: BeuthVerlag GmbH.

|

|