ABSTRACT

This study specifically seeks to find out the changes in moisture content (MC) on two maize varieties (Opeaburoo and Abontem) in relation to designated physical attributes during drying. Four designated MC within a range of 22.3 to 12.8% wb for Opeaburoo and 21.5 to 12.3% wb for Abontem were used. The mean length, width and thickness dimensions reduced from 12.67 to 12.54 mm, 9.19 to 9.12 mm, and 4.58 to 4.51 mm, respectively for Opeaburoo and 11.74 to 10.57 mm, 8.69 to 8.10 mm and 5.43 to 4.79 mm, respectively for Abontem with respect to decrease in moisture content. The symmetrical average diameter, surface area, thousand grain mass and angle of repose also reduced from 8.11 to 8.02 mm, 206.4 to 204.66 mm2, 340.06 to 288.28 g and 28.77 to 22.10°, respectively for Opeaburoo and that of Abontem also recorded similar trend of reduction. Average values for volume lessened from 278.82 to 270.10 mm3 and 290.10 to 214.76 mm3 for Opeaburoo and Abontem, respectively. A non-linear regression equation was found for volume, sphericity and bulk densities in relationship with moisture contents for both varieties. A linear decrease in coefficient of friction with decreasing moisture contents were observed for the three structural surfaces for both maize varieties. The maximum resistance to flow (coefficient of friction) of the grains occurred on the plywood surface. With the exception of the mean width and thickness for opeaburoo, some pairs of the means of the physical attributes for the two maize varieties studied were statistically different at the moisture content levels.

Key words: Geometric mean diameter, sphericity, coefficient of friction, Opeaburoo, Abontem.

The most cereal crop grown after wheat and rice in the world is maize (Plahar, 2006) and belongs to the family Poacea. Maize (Zea mays L) is a major annual crop, yearly grown throughout the world than any other grain crop (Sangamithra et al., 2016). It is widely grown under different climatic conditions and requires favourable warm climate, good drain soil, day light intensity and high soil fertility for better yield. Maize has a wide variety of usage as food, which can be solid, semi-solid and liquid. It is easily digested by animals when fed and the most selected feed ingredient used for compounding of animals feed. Several products such as starch, oil, protein, alcohol and among others are obtained from maize which has vast uses in the pharmaceutical, cosmetic, package, paper, brewery, textile and food industries, respectively (Dzisi et al., 2007; Sangamithra et al., 2016).

Engineering properties of biological materials are useful and necessary in the design as well as selection of appropriate equipment employed in the field of food processing and storage. Among these properties include thermal, electrical, structural, physical, aero dynamic and others. For instance, knowledge of structure of cereal grains is vital for experimenting heat transfer (drying, cooling, freezing and thawing) rate in biological materials. The surface to volume ratio affects the drying rate of agricultural material, the smaller surface-to-volume ratio of a biological material, the faster the diffusion of water.

Estimation of terminal velocity is a useful property for separation in pneumatic conveyors influenced by the density, shape and size of biological material. The anatomical structure of all cereal grains is fundamentally similar, but it may differ from grain to grain and these differences will have effect on the material during various processing operations. For this study, physical properties of two maize varieties as affected by moisture content during drying were analyzed. Understanding the changes of physical attributes of these biological materials as affected by moisture content is imperative to solve problems while designing and selecting appropriate equipment for preservation, processing, packaging and storage. The right equipment designed and selected for processing is essential to ensure food quality and safety. Equipment development for handling, processing and storage has effects on the environment and climate change, hence appropriate data is needed to ensure that once these equipment are manufactured it will serve its purpose to prevent re-invention of same equipment for same purpose which depletes natural resources. The operational efficiency of various types of agricultural machines such as grading, planting and pneumatic transport systems are affected by the axial dimensions and the study of these properties must be done and defined accurately. Empirical data on physical attributes of these two maize varieties will aid in designing and selecting the right equipment for handling, processing and storage which will ensure food quality and safety as well as reduce environmental impact.

Processing of maize requires some form of changes in moisture content of the produce, either soaking or drying. The absorption and desorption of moisture from any agricultural material is partly influence by its physical attributes. These differences in the physical attributes of biological materials require appropriate data to make right choice or design of equipment for processing. Data on physical attributes for locally grown maize varieties in Ghana in literature is inadequate (Bart-Plange et al., 2012). Scientific data on physical properties of any biological material in relation to its moisture content is of prime importance as a basis to aid in designing or selection of appropriate equipment which will be used for processing (drying, winnowing, separation, grading, aeration) as well as equipment for planting, harvesting and storage (Sobukola et al., 2013). For instance, equipment for separation based on electrostatic property of biological material depends on its physical attributes (Mohsenin, 1970). Moisture diffusion during drying is also partly dependent on the size and shape of the material (EÅŸref and Halil, 2007). The energy required for size reduction in milling, heat conduction and selection of dehydrators for optimum processing is contingent upon the geometrical attributes of the material (Pradhan et al., 2009; Singh et al., 2010). Barbosa-Canovas et al. (2006) observed that surface area and porosity are properties affecting the rate of heat conduction in a material and data on this attributes offer basis for design consideration of dehydrators. Other engineering properties such as bulk density, porosity, coefficient of friction and angle of repose are needed during sizing of grain hoppers, flow of materials from silos, harvesting equipment, handling and processing machineries (Amin et al., 2004; EÅŸref and Halil, 2007).

Due to changes in climatic conditions which has resulted in prolonged draughts in many tropical areas, coupled with pest and diseases attack has led crop scientists to come out with improve varieties of crops that can withstand all these unfavourable conditions. The Opeaburoo and Abontem are such two maize varieties introduced by Crop Research Institute (CRI) at Fumesua in Kumasi. These varieties have very high disease and pest resistance, high yielding with early maturity period. Scientific information on the engineering attributes of these two maize varieties is vital to make well informed choices in the selection and design of equipment for planting, harvesting, processing and storage. Literature provides some information on physical attributes of maize varieties locally grown in Ghana (Bart-Plange et al., 2006), however, with several maize varieties currently cultivated, not much information in literature on physical attributes of these local maize varieties are found, of which Opeaburoo and Abontem are of such maize varieties recently introduced.

It is of these reasons that the study sought to analyse the effect of moisture content during drying on some physical attributes of Opeaburoo and Abontem maize varieties. These specifically, consisted of geometric, gravimetric and frictional properties which were examined with respect to their application to equipment design for various pre-harvest and post-harvest operations.

Sample

Two maize varieties (Opeaburoo and Abontem) as shown in Figures 1 and 2 were used for the experimental analysis. A sample size of 2 kg each meant for planting were procured from the Crop Research Institute (CRI) at Fumesua, Kumasi. These were used for the measurements of the various physical attributes. All grains were acquired from the 2017 major crop harvesting season. The grains were received in a clean state and so not much cleaning was done before measurements were taken.

The initial moisture content for the maize varieties after conditioning was 22.3 and 21.5% wb for Opeaburoo and Abontem, respectively. Equation 1 was used to estimate moisture content (MC) in wet basis.

Coefficient of static friction

The coefficient of friction (µ) for each of the sample was estimated on three different structural surfaces, namely plywood, galvanized steel and smooth glass. A cylindrical PVC pipe open at both ends having dimensions of 9.2 and 10 cm, respectively for height and diameter was placed on inclined plane and was filled with grains of a known moisture content. The PVC cylinder was pulled up slightly (about 2 mm) to disjoin with the surface. The tilting table was raised gradually by a screw until the seeds began to slide. The angle between inclined surface with the horizontal when sliding began was measured. The coefficient of static friction (µ) was calculated based on Equation 8 (Üçer et al., 2010; Mohsenin, 1970).

µ = tan θ (8)

Experimental design

Two (2) maize varieties at four levels each of moisture contents (MC) were used for the experiment to determine the physical attributes. At each MC level for each attribute measured, four replications were done and the mean computed.

Data analysis

Data collected were subjected to single factor analysis of variance (ANOVA) using SPC for Excel v6 (trial) hosted on Microsoft Excel 2013 at 5% significance level to determine the effect of moisture content levels on the physical attributes studied. The Least Significance Difference (LSD) was determined to find out whether there were significant differences among the means of the physical attributes studied at the various moisture content levels. Regression equations were also established for the relationship between moisture content and the physical attributes.

Dimensional properties

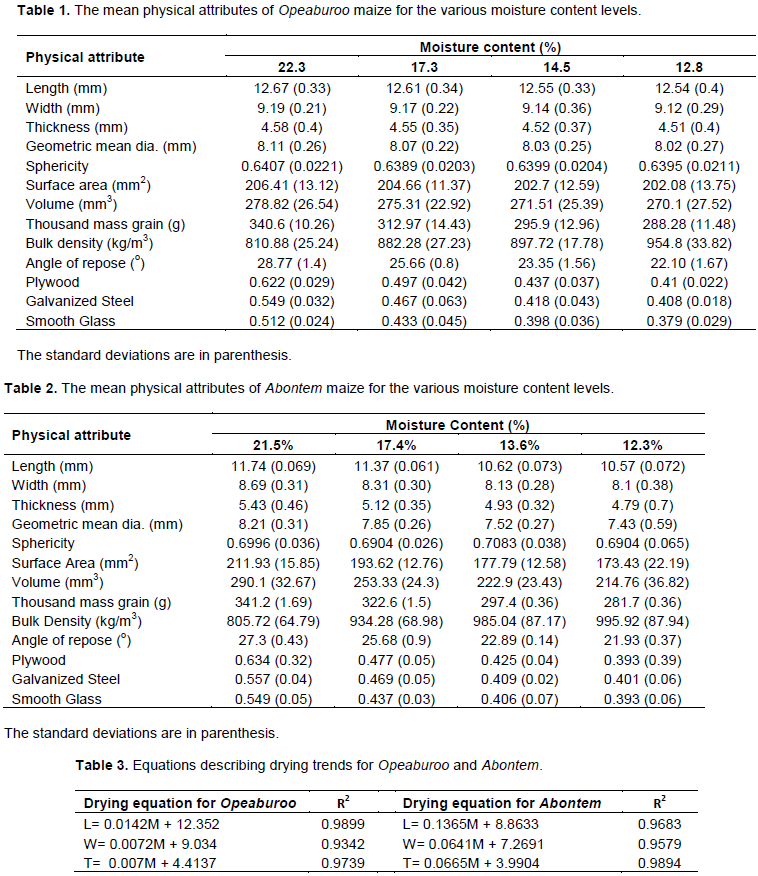

Tables 1 and 2 depict the mean values and standard deviations (in parenthesis) for the principal attributes of Opeaburoo and Abontem maize varieties at the various moisture content (MC) levels, respectively. The axial dimensions for length, width and thickness for Opeaburoo reduced from 12.67 to 12.54 mm, 9.19 to 9.12 mm and 4.58 to 4.51 mm, respectively within a moisture range of 22.3 to 12.8% wb. Abontem variety also saw a reduction in the axial dimensions for length, width and thickness from 11.74 to 10.57 mm, 8.69 to 8.10 mm, 5.43 to 4.79 mm, respectively with reduction in MC from 21.5 to 12.3% wb. Similar trends were observed by Ashwin et al. (2017) and Barnwal et al. (2012) for different maize varieties. For both varieties, the axial attributes decreased with reduction in moisture. The selection and design of sieves for seed winnowing and metering unit for planting is dependent on these properties. The decrease in axial dimensions of the maize varieties was as a result of isotropic shrinkage of the produce due to reduction in MC. The average length, width and thickness for both varieties with respect to changes in MC was evident at p < 0.05. The correlation between the axial dimensions and the MC of the maize varieties were linear and represented in the following regression equations in Table 3.

Geometric mean diameter (Dg)

This property is necessary for determination of average sieves sizes for grading and cleaning. There were changes in geometric mean diameter for Opeaburoo and Abontem from 8.11 to 8.02 mm and 8.21 to 7.43 mm, respectively, as the MC decreased from 22.3 to 12.8% wb for Opeaburoo and 21.5 to 12.3% wb for Abontem. Ashwin et al. (2017), Karababa and CoÅŸkuner (2007) and Bart-Plange et al. (2006) also observed similar characteristics, respectively for maize kennels. Statistical differences were observed in some pairs of the means for geometric mean diameter for both varieties at the various moisture content levels. Equations 9 and 10 depict regression equations of the effect of MC on the Dg for Opeaburoo (Op) and Abontem (Ab) varieties, respectively during drying.

Dg (Op) = 0.0098M + 7.893

R² = 0.9832 (9)

Dg (Ab) = 0.0855M + 6.3672

R² = 0.9993 (10)

Sphericity (Ø)

Sphericity for Opeaburoo and Abontem decreased non-linearly from 0.6407 to 0.6395 and 0.6996 to 0.6904, respectively, with reduction in moisture content (Tables 1 and 2). The effect of moisture content on sphericity was evident at p < 0.05 for both varieties. Some pairs of the means for sphericity for both varieties at the various moisture content were statistically different. Sphericity affects the rate of heat transfer in a material and is a property used to grade material based on its flowability. Similar findings were observed for almond nuts (Aydin, 2003) and coriander seeds (Coskuner and Karababa, 2007). Polynomial Equations (11 and 12) best fit for the drying trends on the effect of MC on sphericity for Opeaburoo and Abontem varieties, respectively. However, Ashwin et al. (2017) found a linear trend of effect of MC on maize for sphericity.

Ø (Op) = -2E-05 + 0.0008M + 0.6321

R² = 0.9874 (11)

Ø (Ab) = 0.0004 - 0.0152M + 0.8299

R² = 0.563 (12)

Surface area (S)

A reduction in MC during drying also affected a linear reduction in surface area for Opeaburoo and Abontem, respectively from 206.41 202.08 and 211.93 173.43 . This attribute is factor to determine the rate of heat transfer in a biological material during drying and cooling. The greater the surface area, the faster the rate of drying. Seifi and Alimardani (2010) and Tavakoli et al. (2009) found an increase in moisture content with corresponding increase in surface area respectively, for corn grains and soy bean. The effect of MC on surface area was evident at p < 0.05 for both varieties. The means of surface area of abontem at the moisture content levels were statistically different; however, this was not same for opeaburoo variety. The regression Equations (13 and 14) correlating the effect of MC on surface area for Opeaburoo and Abontem, respectively were linear. Sobukola et al. (2013) observed a similar trend of linear correlation between MC and surface area for SWAM I maize variety.

S (Op) = 0.4649M + 196.21

R² = 0.9799 (13)

S (Ab) = 4.2125M + 120.95

R² = 0.9799 (14)

Volume (V)

The volume of Opeaburoo and Abontem reduced from 278.82 to 270.10 and 290.10 to 214.76 , respectively, with decreased moisture content (Tables 1 and 2). For accurate modeling to estimate the quantity of heat through a biological material, this attribute is a determinant factor for heat and mass transfer during cooling and heating of biological material. The effect of moisture content on volume of the two maize varieties was significant at p < 0.05. The outcome of MC on volume was non-linear for both varieties of maize. Polynomial regression Equations (15 and 16) were used to express the effect of MC on volume for Opeaburoo and Abontem maize, respectively. However, other researchers found a linear relationship between moisture content and volume for similar products for maize grains (Ashwin et al., 2017), for soybean (Deshpande et al., 1993) and for millet (Baryeh, 2002).

V (Op) = -0.0503 + 2.6685M + 243.92

R² = 0.9909 (15)

V (Ab) = 0.1603 + 2.8163M + 155.48

R² = 0.9909 (16)

Thousand grain mass (TGM)

This physical attribute is used to express the quality of viability of seed material for planting. The quantity of yield of flour is dependent on the endosperm. Grains devoid of physical damage will have higher proportion of milled product to damage grains. The study shown a linear reduction in grain mass from 340.06 to 288.28 g and 341.20 to 281.70 g, respectively, for Opeaburoo and Abontem varieties as MC decreased. The variation in MC to TGM was evident at p < 0.05 for both varieties. At the MC levels for both varieties of maize, the means of TGM were statistically different. Studies on physical attributes on maize, millet and soybean, respectively by Ashwin et al. (2017), Shirkole et al. (2011) and Baryeh (2002) also found linear effects of moisture content on TGM. Equations 17 and 18 depict mathematical expressions for effect of MC on TGM respectively for Opeaburoo and Abontem.

TGM (Op) = 5.6799M + 212.58

R² = 0.9875 (17)

TGM (Ab) = 6.2837M + 208.93

R² = 0.9731 (18)

Bulk density (ρb):

Bulk density for Opeaburoo and Abontem increased non-linearly from 810.88 at 22.3% wb to 954.8 at 12.80% wb and 805.72 at 21.5% wb to 995.92 at 12.3% wb, respectively, with a reduction in moisture content (Figure 3). This attribute is useful for grading and separation of foreign particles from maize grains. From Tables 4 and 5, it is observed that some pairs of the means of bulk density for both varieties of maize were not statistically different. Ashwin et al. (2017) observed a linear increased in MC with decreasing bulk density. Guiotto et al. (2013) found a decreased in bulk the density for chia (Salvia hispanica L.) seeds from 0.713 to 0.644 with increased MC. Polynomial equations best describe the effect of MC on bulk density for the maize varieties. Mathematical expression defining MC and bulk density is shown in Equations 19 and 20.

ρb (Op) = 0.4838 – 30.989M + 1263.1

R² = 0.9514 (19)

ρb (Ab) = -2.0505 + 48.909M + 702.44

R²=0.9992 (20)

Angle of repose

This attribute characterizes the pilling or stacking nature of grains in bins and silos. This study observed a linear reduction in angle of repose from 28.77 to 22.10° and 27.30 to 21.93°, respectively for Opeaburoo and Abontem with a reduction in moisture content as shown in Figure 4. A study on Asontem cowpea (Bart-plange et al., 2012) observed non-linear decreased in angle of repose from 29.35 to 27.91° at a moisture content range of 19.00 to 9.58% wb.

Significant differences were recorded across all means at p < 0.05 for both varieties.

Regression Equations 21 and 22 depict correlation between MC and angle of repose (θ) for Opeaburoo and Abontem maize varieties, respectively.

θ (Op) = 0.7041M + 13.193

R² = 0.995 (21)

θ (Ab)= 0.5916M + 14.867

R² = 0.978 (22)

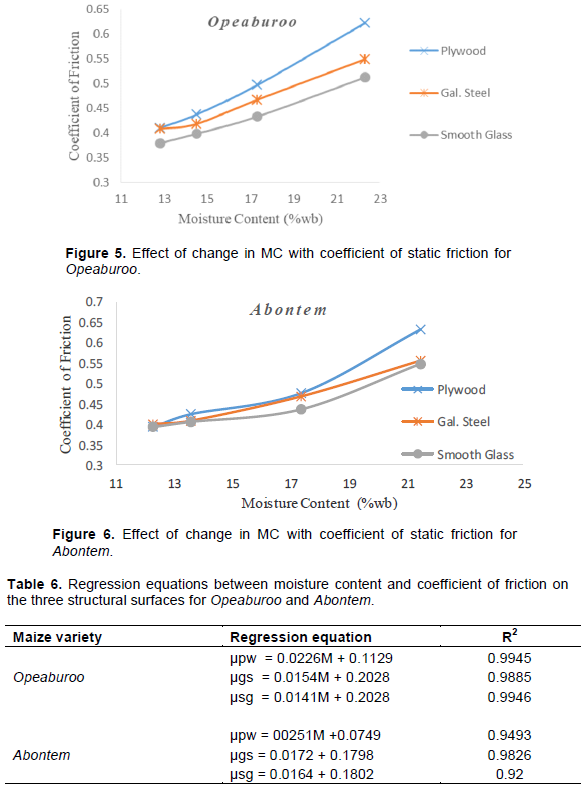

Coefficient of static friction

This physical attribute is necessary to estimate the power require to overcome frictional force to initiate movement of material on structural surfaces. Designing material handling equipment such as conveyors, elevators, silos and bins requires knowledge in the sliding effect of biological material on the surface to which it is contained. For this study, a reduction in MC for the two maize varieties saw a corresponding reduction in coefficient of static friction. Coefficient of static friction for Opeaburoo reduced from 0.622 to 0.410 for plywood, 0.549 to 0.408 for galvanized steel and 0.512 to 0.379 for smooth glass within a MC range of 23.6 to 12.8% wb as shown in Figure 5. A reduction in MC from 21.5 to 12.3 %wb for Abontem, the static coefficient of friction reduced from 0.634 to 0.393, 0.557 to 0.401 and 0.549 to 0.393, respectively, for plywood, galvanized steel and smooth glass (Figure 6). Structural surface (plywood) recorded the maximum static coefficient of friction for both maize varieties, followed by galvanized steel and smooth glass recording the minimum static coefficient of friction. Some means of coefficient of friction for the various structural surfaces were statistically different. The tendency for grains to flow on structural surface made of plywood is relatively low as compared to the other two structural surfaces due to higher frictional resistance on plywood. Increase in MC caused a reduction in flowability among all the structural surfaces due to cohesiveness and adhesives of grain particles impeding flow (Malik and Saini, 2016). Similar observations were made by other researchers on similar structural surfaces with different biological materials (Gharibzahedi et al., 2010b; Tavakoli et al., 2009). The correlation between MC and coefficient of static friction were significant at p < 0.05 for both maize varieties for the three structural surfaces studied. A linear regression equation depicting the effect of MC for the two maize varieties on the µ for the three structural surfaces is shown in Table 6.

The study was conducted to determine moisture-dependence physical properties of Opeaburoo and Abontem maize varieties during drying at a moisture content of 22 to 12.8% wb and 21.5 to 12.3% wb, respectively.

The axial dimensions, geometric mean diameter, surface area, sphericity, volume, bulk density, angle of repose and coefficient of static friction were found to decrease with reduction in moisture contents for both varieties of maize.

A reduction in axial dimensions for length, width and thickness was 12.67 to 12.54 mm, 9.19 to 9.12 mm, 4.58 to 4.51 mm, respectively for Opeaburoo and 11.74 to 10.57 mm, 8.69 to 8.10 mm, 5.43 to 4.79 mm, respectively for Abontem with respect to decreased in moisture content.

The maximum coefficient of static friction for the structural surfaces was recorded in plywood for both maize varieties, followed by galvanized steel and smooth glass recorded the minimum coefficient of static friction.

With the exception of the mean width and thickness of Opeaburoo maize variety, some pairs of the means of the physical attributes studied for both varieties of maize were statistically different at the various moisture content levels.

A linear regression equation was established for axial dimensions, geometric mean diameter, surface area and angle of repose as a function of moisture content, whereas a non-linear regression equation was found for sphericity, volume and bulk density as a factor of moisture content.

The authors have not declared any conflict of interests.

The authors are indebted to Crop Research Institute (CRI) of Council for Scientific and Industrial Research (CSIR) at Fumesua, Kumasi-Ghana for their support in providing the maize varieties for the analysis.

REFERENCES

|

Amin MN, Hossain MA, Roy KC (2004). Effects of moisture content on some physical properties of lentil seeds. Journal of Food Engineering 65(1):83-87.

Crossref

|

|

|

|

Ashwin KB, Rao PVKJ, Edukondalu L (2017). Physical properties of maize grains. International Journal Agriculture Sciences 27(9):4338-4341.

|

|

|

|

|

Aydin C (2003). Physical properties of almond nut and kernel. Journal of Food Engineering 60(3):315-320.

Crossref

|

|

|

|

|

Barbosa-Canovas GV, Juliano P, Peleg M (2006). Engineering Properties of Food in Food Engineering (Ed Gustavo V. Barbosa-Canovas) in Encyclopedia of Life Support System (EOLSS), Developed under the Auspices of UNESCO.

|

|

|

|

|

Barnwal P, Kadam D, Singh K (2012). Influence of moisture content on physical properties of maize. International Agrophysics 26(3):331-334.

Crossref

|

|

|

|

|

Bart-Plange A, Addo A, Dzisi KA (2006). Effects of drying and rewetting on some dimensional and mass properties of'dorke'maize variety. Journal of the Ghana Science Association 8(1):89-96.

|

|

|

|

|

Bart-Plange A, Dzisi KA, Ampah J (2012). Effect of drying on selected physical properties of "Asontem" cowpea variety. ISRN Agronomy, 2012.

Crossref

|

|

|

|

|

Baryeh EA (2002). Physical properties of Millet. Journal of Agricultural Engineering Research 51(1):39-46.

Crossref

|

|

|

|

|

Baryeh EA (2001). Physical properties of bambara groundnuts. Journal of Food Engineering 47(4):321-326.

Crossref

|

|

|

|

|

Coskuner Y, Karababa E (2007). Physical properties of coriander seeds (Coriandrum sativum L). Journal of Food Engineering 80(2):408-416.

Crossref

|

|

|

|

|

Deshpande SD, Bal S, Ojha TP (1993). Physical properties of soybean. Journal of Agricultural Engineering Research 56(2):89-98.

Crossref

|

|

|

|

|

Dzisi KA, Addo A, Bart-Plange A (2007). Strategies for the Development of Good Maize Processing, Handling and storage Systems in Ghana. In: Nsiah-Gyabaah K, Agyepong M, Amoako C, Nyamaah-Koffour K, Adu V, Okyere-Boateng S, Nsiah MK, Aning SK (eds.). Proceedings of Sunyani Polytechnic Lecture Series II. Qualitype Ltd., P. O. Box AN 7314, Accra-North.

|

|

|

|

|

EÅŸref IÅžIK, Halil Ü (2007). Moisture-dependent physical properties of white speckled red kidney bean grains. Journal of Food Engineering 82(2):209-216.

Crossref

|

|

|

|

|

Gharibzahedi SMT, Etemad V, Mirarab-Razi J, Foshat M (2010a). Study on some engineering attributes of pine nut (Pinus pinea) to the design of processing equipment. Research in Agricultural Engineering 56(3):99-106.

Crossref

|

|

|

|

|

Gharibzahedi SMT, Mousavi SM, Moayedi A, Garavand AT, Alizadeh SM (2010b). Moisture-dependent engineering properties of black cumin (Nigella sativa L.) seed. Agricultural Engineering International: CIGR Journal 12(1).

|

|

|

|

|

Guiotto EN, Ixtaina VY, Tomás MC, Nolasco SM (2013). Moisture-dependent engineering properties of chia (Salvia hispánica L.) seeds. In Food Industry. InTech.

|

|

|

|

|

Jony A (2017). Drying and quality features of selected maize varieties dried in commercial processing complexes. Agricultural Engineering International: CIGR Journal 19(3):148-155.

|

|

|

|

|

Karababa E, CoÅŸkuner Y (2007). Moisture dependent physical properties of dry sweet corn kernels. International Journal of Food Properties 10(3):549-560.

Crossref

|

|

|

|

|

Malik MA, Saini CS (2016). Engineering properties of sunflower seed: Effect of dehulling and moisture content. Cogent Food and Agriculture 2(1):1145783.

Crossref

|

|

|

|

|

Mohsenin NN (1970). Physical properties of plant and animal materials. Gordon and Breach Science Publishers.

|

|

|

|

|

Plahar WA (2006). Overview of the Grain industries in Ghana. Available at:

View.

|

|

|

|

|

Pradhan RC, Naik SN, Bhatnagar N, Vijay VK (2009). Moisture-dependent physical properties of jatropha fruit. Industrial Crops and Products 29(2-3):341-347.

Crossref

|

|

|

|

|

Sangamithra A, Swamy GJ, Sorna PR, Nandini K, Kannan K, Sasikala S, Suganya P (2016). Moisture dependent physical properties of maize kernels. International Food Research Journal 23(1):109-115

|

|

|

|

|

Seifi MR, Alimardani R (2010). Comparison of moisture-dependent physical and mechanical properties of two varieties of corn (Sc 704 and Dc 370). Australian Journal of Agricultural Engineering 1(5):170.

Crossref

|

|

|

|

|

Shirkole SS, Kenghe RN, Nimkar PM (2011). Moisture dependent physical properties of soybean. International Journal of Engineering Science and Technology 3(5):3807-3815.

Crossref

|

|

|

|

|

Singh KP, Mishra HN, Saha S (2010). Moisture-dependent properties of barnyard millet grain and kernel. Journal of Food Engineering 96(4):598-606.

Crossref

|

|

|

|

|

Sobukola OP, Kajihausa OE, Onwuka VI, Esan TA (2013). Physical properties of high quality maize (Swam 1 variety) seeds (Zea mays) as affected by moisture levels. African Journal of Food Science 7(1):1-8.

Crossref

|

|

|

|

|

Tavakoli H, Rajabipour A, Mohtasebi SS (2009). Moisture-dependent some engineering properties of soybean grains. Agricultural Engineering International: CIGR Journal 1110:11.

|

|

|

|

|

Tunde-Akintunde TY, Akintunde BO (2007). Effect of moisture content and variety on selected physical properties of beniseed. Agricultural Engineering International: CIGR Journal FP 07 021:9.

|

|

|

|

|

Üçer N, Kiliçkan A, Yalçin I (2010). Effects of moisture content on some physical properties of red pepper (Capsicum annuum L.) seed. African Journal of Biotechnology 9(24):3555-3562.

|

|

|

|

|

Varnamkhasti MG, Mobli H, Jafari A, Keyhani AR, Soltanabadi MH, Rafiee S, Kheiralipour K (2008). Some physical properties of rough rice (Oryza Sativa L.) grain. Journal of Cereal Science 47(3):496-501.

Crossref

|

|