Full Length Research Paper

ABSTRACT

Sorghum, sesame seeds and baobab fruit are commercially viable, underutilized crops in sub-Saharan Africa with potential for use in development of high-quality value-added products for food and nutritional security. This study evaluated effects of processing methods on the nutritional and sensory attributes of a ready to eat snack bar developed from sorghum supplemented with sesame and baobab fruit pulp powder. The moisture content ranged between 6.38 and 10.28%, total fiber content ranged between 5.59 and 10.455 g/100 g while protein and fat content ranged between 11.28 and 16.74 g/100 g and 9.65 g/100 g and 18.58 g/100 g, respectively. The carbohydrates content in the snack bars ranged between 46.37 and 60.31 g/100 g, while energy content averaged 426.33 kcal/100 g for raw materials and 414.38 kcal/100 g for formulated snack bars. Concentrations of iron, calcium and zinc ranged between 5.46 and 14.611 mg/100 g, 82 and 246 mg/100 g, and 1.377 and 4.98 mg/100 g, respectively. Sensory evaluation of the bars formulations was based on a 5-point hedonic scale and revealed significant differences (p<0.05) in color, taste and overall acceptability. The aroma and crunchiness of the snacks were not significant. The study found underutilized crops have the versatility to improve the range of products and spur innovation in new product development.

Key words: Sorghum, sesame, baobab, malting, roasting, fermentation, supplementation.

INTRODUCTION

Sorghum is an important underutilized cereal in Africa due to its drought resistance (Chikuta et al., 2014). Ranked the fifth most important cereal, sorghum provides protein and energy through gruels to many people in sub-Saharan Africa (Pelembe et al., 2002). The biochemical composition in sorghum structure generally compares with other cereals with some minor compositions (Taylor and Kruger, 2019). Sorghum is high in fiber content, protein though deficient in lysine content, starch and good distribution of micronutrients albeit in low levels (Serna-saldivar et al., 2019). In addition, sorghum has limiting levels of sulphur containing amino acids such as cysteine and methionine (Pelembe et al., 2002). Hence, there is the need to complement the biochemical composition of sorghum with an oil seed such as sesame for protein and polyunsaturated fatty acids (Hegde, 2012)and baobab fruit which is noted for its ascorbic acid and mineral content (Aluko et al., 2016).

Sesame (Sesamum indicum L.) is an important oil seed that is widely grown in some parts of Africa and Asia (Asghar et al., 2014). Sesame seed is noted for its high protein content at ranges of 17 to 32% and abundant quantities of oil at 40 to 50% and laden with tocopherols (Gharby et al., 2015). In addition, sesame is rich in calcium, phosphorous and iron (Onsaard, 2012). Thus, sesame seeds have found a multitude of uses across the food industry such as processing of margarines, oil, sauces (Hiremath et al., 2010)but not limited to production of soaps and lubricants in the non-food niche (Nyongesa et al., 2013). However, despite the nutritional and industrial importance of sesame, its cultivation and yield remains low in Kenya averaging 400 kg ha-1 (Nyongesa et al., 2013), with its range of applications limited to roasted seeds and sesame oil (Koitilio et al., 2018).

Further, it has been shown that Baobab (Adansonia digitata L., Malvaceae) is localized in lower Eastern and coastal parts of Kenya where it remains as a wild undomesticated tree (Muthai et al., 2017). The importance of baobab is underpinned as the tree is composed of edible leaves, seeds and fruit pulp (Muthai et al., 2017). The baobab fruit pulp is particularly noted for its high ascorbic acid content reported at 337 mg/100 g pulp (Momanyi et al., 2020). The pulp has significant levels of micronutrients particularly calcium, zinc and potassium (Aluko et al., 2016), however, it has low levels of protein and fat content (Momanyi et al., 2020).

These orphan crops have been underutilized in production of value-added products for commercialization. In sub-Saharan Africa, a significant portion of sorghum is utilized in form of thin and thick gruels (Kilambya, 2013), for sesame, it has been used widely as roasted snack balls and as toppings in baked goods (Amoo et al., 2017) while baobab fruit remains largely unexploited. Therefore, there is need for diversifying these crops for end products that are nutritious, convenient aligned to increased consumer awareness. Popkin (1999)noted increased nutrition shift towards consumption of superior grains of rice, wheat and maize while indigenous cereals such as sorghum have been neglected and christened a poor man’s crop (Hadebe et al., 2017; Orr, 2017). Snacks are ready-to-eat products which have been characterized by high calorie, low nutritional density and has contributed to increased incidences of lifestyle diseases such as diabetes and cardiovascular diseases (Popkin, 2015; Bhurosy and Jeewon, 2016). Development of sorghum-based snacks has yet to be fully exploited, and which has the potential to improve its utilization.

In particular is sorghum, which is laden with anti-nutrients that can chelate available micronutrients (Singh et al., 2016). As a result, sorghum is reported to have a poor starch and protein digestibility (Taylor and Taylor, 2017). Traditional processing methods of malting and fermentation have a profound effect on the digestibility of sorghum. Prior studies have revealed that fermentation and malting processes lead to a surge in the endogenous activity of sorghum via de novo activation of inherent phytases (Onyango et al., 2013). Roasting has the effect of imparting desirable sensory qualities whilst also denaturing anti-nutrient factors such as trypsin inhibitors (Adedeji et al., 2015; Msheliza et al., 2018).

The potential of incorporating these components in developing a nutritious ready-to-eat snack bar will improve their utilization, whilst alleviating consumer health concerns regarding snacks. This study was aimed at formulating and analyzing the effect of sorghum treatment methods and incorporation of sesame and baobab on the nutritional and biochemical composition of the developed snack bar.

MATERIALS AND METHODS

Sample preparation

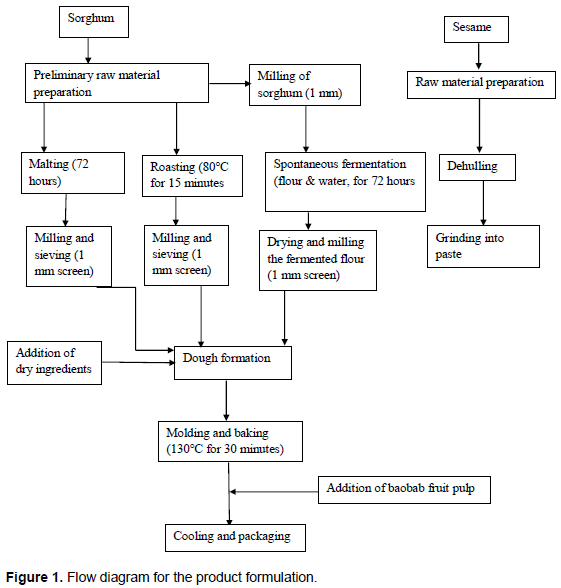

Sorghum (Sorghum bicolor L. Moench) and sesame (S. indicum L.) seeds were sourced from Kangemi market, Nairobi while dried baobab fruits were sourced from Makueni County, Kenya. Preliminary steps of cleaning, grading, removal of broken kernels and foreign matter were done at the Department of Food Science, Nutrition and Technology, College of Agriculture and Veterinary Sciences, University of Nairobi.

Sorghum grains were prepared in three batches through malting, fermentation and roasting processes. The sorghum grains were steeped in water (2:1, w/v) for 18 h, the malted batch was placed in damp muslin cloths and allowed to germinate for 72 h. For the roasted batch, the steep grains were air-oven dried at 105°C for 3 h, and thereafter roasted at 180°C for 15 min in an open pan. For the fermented batch, the steeped cereals were oven dried at 105°C for 3 h and milled into 1 mm particle size. The flour was added to potable water followed by spontaneous fermentation by lactic acid fermentation under anaerobic conditions for 48 h. The fermented flour was oven dried at 105°C for 3 h and milled back into 1 mm flour.

Sesame seeds were cleaned, and steeped in water for 18 h. Sesame seeds were dehulled by method described by Inyang and Ekanem (1996)with some modifications. The steeped seeds were soaked in 10% NaCl solution for 12 h. The seeds were thereafter consecutively washed thoroughly with water and rubbed by hands so as to decorticate them. The water was drained off and the seeds air oven-dried at 65°C for 3 h. The dried seeds were separated from the hulls by winnowing thereafter pan roasted at 110°C for 15 min in a pan to impart desirable sensory qualities.

The baobab fruits were cleaned and the dried pulp scrapped out with a knife on clean containers. The seeds were separated from the scraped-out pulp. The pulp was crushed in a blender (Krups, Model Type KB703, Mayenne - France) which reduced the pulp to fine particles of 1 mm.

Formulation(s) of ready-to-eat snack bars

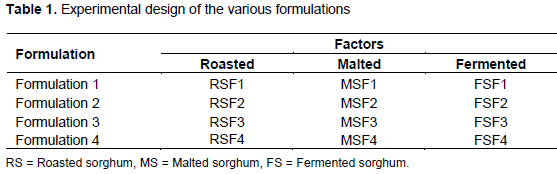

The formulations consisted of fermented, malted and roasted sorghum, roasted sesame and baobab fruit modeled in a 3 × 4 full factorial experiment by Nutrisurvey 2007 version (Erhardt, 2007) and Momanyi et al. (2020). Baobab fruit pulp powder substitution levels were determined by Momanyi et al. (2020)owing to their astringency nature in levels above 20%. Table 1 shows the factors and formulations developed.

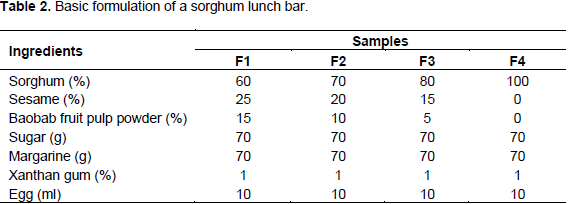

The sorghum flour variations were added at different proportions with dry ingredients of sugar, hydrogenated margarine, egg white and xanthan gum, and were stirred vigorously. The ingredients were standardized for all factors of roasting, malting and fermentation. Xanthan gum was added as a binding agent at 1% level of total flour weight (Shittu et al., 2009; Preichardt et al., 2011). The liquid egg white functioned as an emulsifying agent, while the margarine was added to improve the texture of the dough, due to the rough texture of sorghum attributed to the coarse grits formed during milling which causes a sandy mouthfeel (Onyango et al., 2011)while also replacing the use of water. To this mixture, sesame paste was incorporated and it was stirred well. The sesame paste was prepared by taking the previously dehulled roasted sesame seeds and grinding them into a fine paste in a blender (Krups, Model Type KB703, Mayenne - France). The dough was placed in pre-molds and baked at 130°C for 30 min. Baobab fruit pulp was sprinkled on the formulations, then remolded and packaged. Table 2 indicates the ingredient formulation for the snack.

Nutritional analysis

The nutritional content of the snack bars was determined as per AOAC (2005) methods in terms of moisture content (method 930.15), crude protein (N 6.25) by the Kjeldahl method (method 978.04), crude fibre (method 978.10) and crude fat (method 930.09). Carbohydrate content of the snack was by difference method as described in AOAC (2000). Total energy of the snacks was determined as per the formula described by Momanyi et al. (2020):

Total energy (kcal/100 g) = [(%Carbohydrates × 4) + (%Protein × 4) + (Fat × 9)]

Mineral analysis

Iron, calcium, and zinc were determined by wet digestion method as described by Palma et al. (2015). 0.5 g of sample(s) was digested by HNO3:HClO4 (2:1) at 260°C for 3 h. Thereafter, the samples were topped up with 50 ml distilled water. The specific minerals of Fe, Zn and Ca were determined by AAS spectrophotometry (Model 210 VGP). Standards solutions of Fe, Zn, and Ca were prepared and used to prepare a calibration curve. Fe was measured at 248 nm, Zn at 213.9 nm and Ca at 422.7 nm.

Concentration was calculated as:

((Absorbance - Blank) / 10 × Sample weight) × V = mg/100 g

Where V = is the volume of distilled water topped up to the mark.

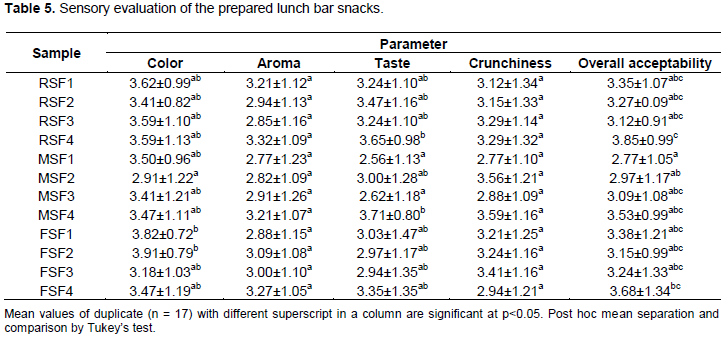

Sensory analysis

The sorghum snack bar was assessed by a semi-trained panel consisting of undergraduate, postgraduate students and staff from the Department of Food Science and Technology at the University of Nairobi. A 5-point hedonic scale (1= dislike extremely to 5= like extremely) was used to assess color, taste, crunchiness, aroma and overall acceptability. Clean water was provided to the panelists for rinsing their mouths after evaluating each sample so as to minimize errors during the process.

Statistical analysis

The analysis was done in duplicates. Collected data was statistically analyzed by GenStat software version 15.0 at P?0.05 significance level. Data was subjected to a one-way ANOVA to determine the least significant difference at p ≤ 0.05 and post hoc mean separation and comparisons performed by Tukey’s multiple range test.

RESULTS

Moisture content

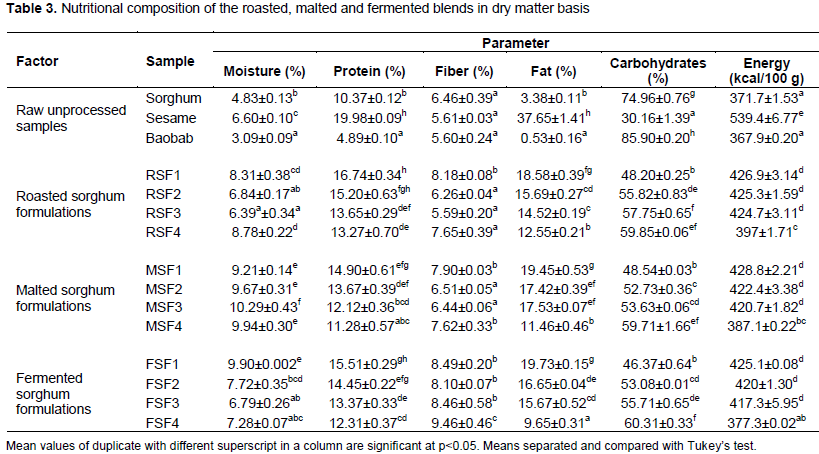

The moisture content of the formulations is shown in Table 3. There were significant differences in all formulations (p<0.05) with values ranging from 6.39 to 10.29% DM. The raw unprocessed samples were 4.83, 6.60, and 3.09% for sorghum, sesame and baobab, respectively. The roasted sorghum formulations had moisture content values ranging from 6.39 to 8.78% DM. Malted sorghum formulation moisture levels ranged between 10.29 and 9.21% DM while fermented sorghum formulations ranged between 6.79 and 9.90% DM. The moisture values in malted sorghum had slightly elevated moisture levels as compared to roasted and fermented sorghum formulations.

Protein

There were significant differences (p<0.05) in the protein content in the formulations. Roasted sorghum formulations had protein content levels ranging between 13.27 and 16.74%, malted sorghum formulations ranged between 11.28 and 14.90%, whereas fermented sorghum formulations ranged between 12.31 and 15.51%/100 g DM (Table 3). The unprocessed sesame had high overall protein content (19.98%) compared to sorghum (10.37%) and baobab fruit pulp (4.89%). The trend in all formulations showed a decrease in protein content with low sesame supplementation. Thus, the trend indicated higher sesame substitution levels at 25% have a positive net improvement in overall protein content. Formulations RSF4, MSF4, and FSF4 had least protein levels as they had no sesame in them. In addition, roasted and fermented sorghum formulations had improved protein content as compared to malted sorghum formulations which were slightly lower compared to the two.

Fiber

The fiber content of the samples is presented in Table 3. The formulations had improved fibre content as compared to the raw unprocessed samples. The fiber levels were not significant (p>0.05) for the raw unprocessed samples at 6.46, 5.61 and 5.60% for sorghum, sesame and baobab fruit pulp respectively. Significant differences (p<0.05) among the roasted formulation of RSF1, malted formulation of MSF1 and MSF4 and fermented formulation FSF4, respectively. Crude fibre content ranged between 5.59 and 8.18% for roasted sorghum formulations, 6.44 and 7.90% for malted sorghum formulations and 8.10 and 9.46% for fermented sorghum formulations, respectively. The trend expresses the fermented sorghum formulations to have improved fiber content as compared to roasted and malted sorghum formulations. In addition, sesame seeds substitution had no marked impact on overall fiber levels.

Fat

The fat content in the snack bar formulations is as presented in Table 3 was significant at p<0.05. The raw unprocessed sesame seeds had the highest fat content (37.65%) compared to raw sorghum (3.38%) and baobab fruit pulp (0.53%) which had the least content. Roasted sorghum formulations fat content levels ranged between 12.55 and 18.58%, malted sorghum formulations ranged between 11.46 and 19.45%, while fermented sorghum formulations fat levels were between 9.65 and 19.73% (Table 3).

Carbohydrates and energy content

The carbohydrate content of the formulations is shown in Table 3. There was significant differences (p<0.05) in the carbohydrate content across the various formulations with roasted sorghum formulations had carbohydrate content ranging between 48.20 and 59.85%/100 g DM, malted sorghum formulations ranged between 48.54 and 59.71%/100 g DM and fermented sorghum formulations at 46.37 and 60.31%/100 g DM.

Table 3 presents the energy content expressed in kcal/100 g of the formulations. The roasted sorghum formulations energy content was between 397 and 426.9 kcal/100 g, malted sorghum formulations were between 387.1 and 428 kcal/100 g and fermented sorghum formulations were between 377.3 and 425.1 kcal/100 g.

Mineral content

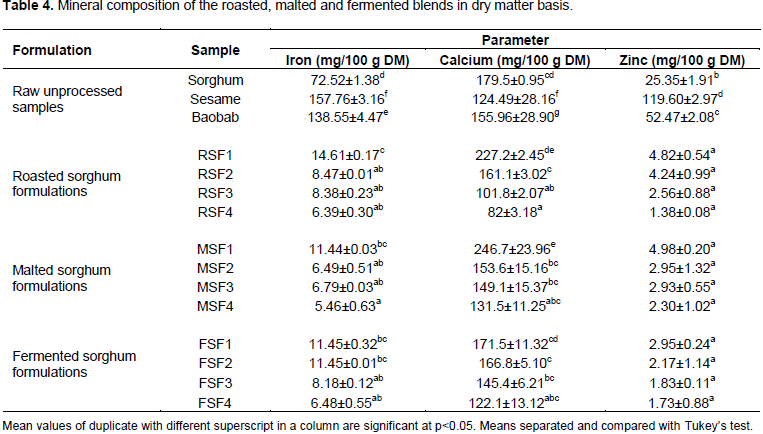

Iron content was high in raw sesame (157.76 mg/100 g) as compared to sorghum and baobab fruit pulp powder. Iron content in all formulations were significantly different at p<0.05 with RSF1 recording highest content at 14.61 mg/100 g. The roasted sorghum formulations iron content ranged between 6.39 to 14.61 mg/100 g, malted sorghum formulations at 5.46 to 11.44 mg/100 g, and fermented sorghum formulations were at 6.48 to 11.45 mg/100 g.

The calcium content varied significantly (p<0.05) among the snacks. The trend shows improved calcium levels in the formulations. Roasted sorghum formulations had calcium content between 82 to 227.2 mg/100 g, malted sorghum formulations were between 131.5 and 246.7 mg/100 g, whilst fermented sorghum ranged between 122.1 and 171.5 mg/100 g. The formulation(s) MSF1 recorded the highest concentration (246.7 mg/100 g) while RSF4 recorded the least amount at 82 mg/100 g. High calcium content was realized at 15% baobab supplementation level in RSF1, MSF1 and FSF1.

The zinc content varied significantly (p<0.05) among the formulations with roasted formulations ranging between 1.38 and 4.82 mg/100 g, malted sorghum formulations ranged between 2.30 and 4.98 mg/100 g and fermented sorghum zinc content ranged between 1.73 and 2.95 mg/100 g (Table 4). The processing effect on zinc content was not significant (p>0.05) across the formulations, but higher zinc contents were observed with increase in sesame seeds and baobab fruit pulp concentrations.

Sensory analysis results

Table 5 presents the sensory scores of the sorghum-based snack bars. The results show that the sensory perception of color, aroma, taste crunchiness and the overall acceptability of the snack bars were not significantly different (p>0.05) across the treatments of roasted-, malted-, and fermented sorghum-based snack bars.

DISCUSSION

Moisture content

Cereal snack products are normally associated with low moisture levels primarily attributed to processing techniques involving heat treatment. Moisture content ranges as outlined in Table 3 are in agreement with Momanyi et al. (2020)who reported moisture levels between 9.43 and 9.5%. The slight increase in water content could be attributed to sesame which in its composition has elevated moisture levels. The malted sorghum formulations had slightly elevated moisture levels which could be attributed to release of metabolic water during malting and resultant drying regimes (Asuk et al., 2020). Low moisture content in cereal baked goods is essential in maintaining the microbiological integrity thus extending their shelf life (Kince et al., 2017). Yeast and molds are common spoilage microorganisms in low moisture cereal products and thus water activity below 0.65 is preferable in retarding their growth.

Protein content

High supplementation of sesame seeds at 25% in the formulations resulted in protein quality enhancement in the snack bars (Table 3). The trend in crude protein content in the roasted, malted and fermented sorghum snack bars decreased with decreased supplementation of roasted sesame (Figure 1). Sesame seeds have been profiled to contain up to 18 to 25% protein (Tenyang et al., 2017)and rich in essential amino acids tryptophan and methionine (Lawal et al., 2019). In addition, dehulling roasting sesame seeds had no effect on protein quantity which agrees with studies by Lawal et al. (2019). Thus, by supplementing sesame seeds, there is overall improvement in overall protein quality which is essential in combating protein energy malnutrition.

There was observed effects of processing on crude protein among the formulations. The protein content has been reported to range between 11.5 and 12.3% (Serna-saldivar et al., 2019), thus processing techniques are essential in improving the overall protein content. Roasted sorghum formulations snacks had higher crude protein content when compared with fermented formulations (12.31 15.51% g/100 g) and malted formulations (11.28 to 14.90% g/100 g) as per Table 3. These observations agree with Tamilselvan and Kushwaha (2020)who recorded increase in crude protein during fermentation and net reduction during malting of sorghum. Malted sorghum formulations had lower crude protein content which could be due to degradation of proteases present which are synthesized during the germination period (Nkhata et al., 2018). Roasting of sorghum disrupts the encapsulated protein in the endosperm complex thus releasing the stored protein (Ratnavathi, 2016). These could be attributed to the high crude protein content in roasted sorghum formulations as compared to the malted and fermented snack bars. Sorghum proteins are localized in the endosperm, germ and pericarp and fermentation has been attributed to breakdown these complexes by action of microorganisms (Tamilselvan and Kushwaha, 2020). Improved crude protein during fermentation may be attributed to breakdown of complex sorghum kafirins thus releasing peptides and amino acids particularly lysine and improving their digestibility (Nkhata et al., 2018).

Thus, the combined effects of sesame supplementation and processing methods had a net effect in overall crude protein content in the snack bars.

Fiber content

Sorghum is a rich source of dietary fiber that is associated with its pericarp and endosperm walls, usually ranging from 6 to 9.3% (Stefoska-needham et al., 2015; Serna-saldivar et al., 2019). The fiber in sorghum is largely the insoluble type which has been associated with decrease in gastrointestinal problems, glycemic control and slow release of glucose into the bloodstream (Stefoska-Needham et al., 2015).

The effect of substitution across the processing methods of roasting, malting and fermentation with sesame and baobab fruit pulp did not yield an increase in crude fiber. Sesame seeds have fiber in the range of 6 to 8% concentrated in their hull layers (Hegde, 2012), while baobab fruit has been reported in the 6 to 8 g/100 g (Muthai et al., 2017). Dehulling is done on sesame seeds to remove the hull which contains significant oxalic acid that have a bitter taste and as a consequence, most crude fiber is lost in the process. That could be a possible reason for sesame seeds not improving the overall crude fiber content in the snack bars. Nevertheless, the crude fiber content in fermented snack bars was comparatively higher when compared with roasted and malted snack bar formulations. The findings agree with Mohapatra et al.(2019)who observed increase in fiber content from 2.76 to 3.41% in fermenting sorghum grain. However, the findings from malted sorghum snack bars indicate lower crude fiber content relative to fermented snack bars. These are contrary to findings by Ogbonna et al. (2012)who reported increase in crude fiber by 72.5% by malting sorghum grist. Sprouting of sorghum could have reduced the crude fiber due to degradation of cell walls during sprouting (Taylor and Kruger, 2019). In addition, by subjecting sorghum to roasting temperatures ruptures the endosperm complex, thus degrading the starch and fiber content (Taylor and Kruger, 2019).

Thus, the result findings suggest fermentation has positive effect on the crude fiber content as compared to roasting and malting. In addition, dehulling of sesame has net negative on crude fiber; however, the process is necessary for reduction in the bitter oxalates.

Fat content

Sesame seeds have significant levels of oil content in the upward ranges of 48 to 55% (Hegde, 2012). Baobab fruit pulp is usually low in fat content, with some studies reporting contents in the average of 0.5 to 2% (Zahrau et al., 2014; Aluko et al., 2016). High fat content in the formulations was attributed to the roasted sesame seeds. The trend indicated increased fat content with improved sesame supplementation among formulations RSF1, MSF1 and FSF1 with 25% sesame supplementation recording high fat content. Thus, as the level of sesame seeds were increased in the formulations, there was a net positive improvement in the fat content. Snacks have a reputation for saturated fats content which renders dietary fears among potential consumers due to associated health risks such as heart diseases, hypertension and diabetes. However, sesame oil is rich in unsaturated fats of oleic and linoleic fatty acids that have beneficial health benefits of lowering of blood cholesterol levels and reducing the risk of heart related ailments (Anilakumar et al., 2010).

Carbohydrates and energy content

Previous studies have reported the contribution of available carbohydrates by sorghum to contribute to 72% of its total weight (Stefoska-Needham et al., 2015), raw sesame seeds have 20 to 25% (Onsaard, 2012)and baobab fruit pulp at 74% (Oyeleke et al., 2012). Processing of sorghum by fermentation reduced available carbohydrate attributed to decrease in dry matter by Lactobacillus plantarum (Mugula and Lyimo, 2000). The corresponding benefit contributes to carbohydrates bioavailability encapsulated in the sorghum’s endosperm (Taylor and Kruger, 2019). The malted snack bar samples had reduced total carbohydrates which could be attributed to metabolism during steeping and sprouting periods (Ogbonna et al., 2012). Similar observations by Folasade and Makanjuola (2012)observed a significant decrease in carbohydrate for a sorghum based kunun-zaki supplemented with sesame seeds from 80.67 to 63.59%. Thus, while the snack bars had reduced carbohydrates, the corresponding benefit is improved fat and protein content which have important roles in cell metabolism.

Snack bars are preferred due to their nutritional density, convenience and source of energy. There is improved energy intake with increase sesame and baobab fruit supplementation. This could be attributed to high oil content in sesame which once metabolized by body cells, releases energy.

Energy requirements are dependent on factors such as the person’s age, sex, height, weight and level of physical activity. Fermented snack bars exhibited slightly higher energy content which could be attributed to the role of microorganisms in improving the starch and protein digestibility. For malted snack bars, there is the possibility of respiration during the germination period that depletes some of the stored starches, which ultimately has an effect on the overall energy content.

Two servings of the formulated snack bars will meet the total RDI for men and women >19 years old who have a moderate active lifestyle and who need minimum of 1600 kJ in women and 2000 kJ in men (USDA and HHS, 2015). The snack bar FSF4, with least energy content (Table 3) which recorded 1578.62 kJ will meet 98% of total RDI for children < 8 years old (USDA and HHS, 2015). For teenagers with moderate active and active lifestyles, the snack bars will adequately their total energy RDA (USDA and HHS, 2015). It should be noted that while estimates are provided, the differences in basal metabolic rates among men and women will ultimately determine needed energy content.

Mineral content

Iron is an important micro-nutrient in diets which is important in formation of hemoglobin in the body. The processing steps thus had the effect on mineral content in final formulations.

Fermentation has the positive impact of breaking down tannins and phytates in the sorghum and this is indicated by positive iron concentration in FSF1, FSF2, and FSF3. This suggests that while sesame was dehulled, fermentation of sorghum is efficient in releasing complexed iron content. In contrast, the malted sorghum bars recorded lower iron content which is contrary to past observations that sprouting has a positive effect on mineral content. It is postulated by sprouting, the process reduces antinutrients present thus improving their bioaccessibility (Taylor and Kruger, 2019). It can be deduced that leaching of iron during steeping and dehulling of sesame reduced iron contribution, however, contrary observations by Folasade and Makanjuola (2012)found improved mineral content for sorghum based kunun-zaki supplemented drink supplemented with sesame prepared by washing, steeping, wet milling and sieving.

Calcium is essential for bone development, cardiac and muscular contractions, transmission of nerve impulses and coagulation of the blood (WHO, 2001). The formulation(s) MSF1 recording the highest concentration (246.7 mg/100 g) and RSF4 recording the least amount at 82 mg/100 g. High calcium content was realized at 15% baobab supplementation level in RSF1, MSF1 and FSF1. Sesame seeds hulls have predominant calcium fractions, which once dehulled, lowers its content (Hegde, 2012). Thus, predominant calcium in the formulations was provided by baobab fruit pulp. Various authors have evaluated the baobab fruit pulp and found high calcium levels at 430 mg/100 g (Muthai et al., 2017)and 128 mg/100 g (Amarteifio and Mosase, 2009). The trend shows improved calcium levels in the formulations. However, snack bars RSF4, MSF4, and FSF4 had no supplementation. The malted bar, MSF4 compared better to FSF4 and RSF4 which can be attributed to processing parameters during malting such as type of water used, steeping and deculming steps. In particular, the breakdown of anti-nutrients present especially phytates contents, makes calcium more bioavailable in sorghum (Taylor and Kruger, 2019). The least calcium concentration in formulation RSF4 (82 mg/100 g) could be attributed to roasting temperatures not able to breakdown the anti-nutrient elements so as to release complexed calcium content.

The processing effect on zinc content was not significant (p>0.05) across the formulations, but a difference with increase in sesame seeds and baobab fruit pulp. Zinc is essential for gene expression, metabolic breakdown of proteins, carbohydrates and fats and forms part of the enzyme structure and proteins (WHO, 2001).

Sensory analysis

There were no significant differences in the aroma and crunchiness of the snack bars (p>0.05) with average sensory scores of 3 indicative of the perception of neither liking nor dislike. These results are in agreement with Momanyi et al. (2020), the effect of beany flavor in cowpeas lowered the scores. Sesame seeds have significant oil content which is utilized in frying operations (Hwang, 2005), and roasting their seeds enhances the aroma. Furthermore, malting of sorghum involves activation of endogenous enzymes, release of starch content, which, during baking, improves the overall flavor of the snacks. For the fermented snacks, the prevalence of residue lactic acid that could have added an acidic taste was minimal. Snack bars are appealing to consumers due to their crunchy nature. Furthermore, the fiber content in sorghum maintains its rough texture if milling or sifting is inadequate. The prepared snacks were not significant with sensory scores <3.5. Sorghum has characteristic rough nature which processing operations of malting and fermentation have a great impact in reducing its fiber content to soluble form.

The trio of roasted, malted and fermented sorghum treatments had a dark color (sensory score >3). The prevalence of dark color was attributed to higher sesame seed supplementation which caramelizes during roasting process, and lower baobab levels. These observations agree with Momanyi et al. (2020), where the color of lunch bars were comparatively darker with increase in cowpea and low baobab supplementation. In addition, roasting sorghum improved the appearance due to maillard reactions of its stored starch levels (Taylor and Kruger, 2019). The palatability of the snack bars was significant (p<0.05) among the panelists. Samples MSF4 and RSF4 with 0% sesame and baobab were most preferred with MSF1 and MSF3 least preferred. Baobab has characteristic astringency taste due to high vitamin C content. Momanyi et al. (2020)points that supplementation of baobab above 25% levels will consequently have a characteristic bitter taste in the final product which is not acceptable amongst most consumers. Sesame which is sweet can be overwhelmed by the astringency in the baobab fruit, and generally, snacks with lower baobab were preferred.

In general, the snack bars had an acceptability score of between 2.76 and 3.67, p<0.05. The mark of good quality is a rating score of ≥4 on a 5-point hedonic scale. The skepticism among consumers regarding new product could be a factor for the low overall acceptability scores.

CONCLUSION

A nutritional viable ready-to-eat snack bar at supplementation level of sorghum, sesame and baobab fruit was due to high protein, fat and mineral content as compared to subsequent supplementation levels. This level of supplementation will address issues of protein energy malnutrition and low nutrient density associated with highly processed snacks. The sensory attributes of the snack bars were not affected by processing modes of roasting, malting and fermentation and influence of sesame seeds and baobab fruit. Nevertheless, this study demonstrates the potential of underutilized crops in food product innovation.

CONFLICT OF INTERESTS

The authors have not declared any conflict of interests.

REFERENCES

|

Association Official Analytical Chemist (AOAC) (2000). Methods of analysis of AOAC International. AOAC International, Maryland, USA (2003). |

|

|

Association Official Analytical Chemist [AOAC], 2005. Official methods of analysis. |

|

|

Adedeji O, Jegede D, Abdulsalam K, Umeohia U, Ajayi O, Iboyi J (2015). Effect of processing treatments on the proximate, functional and sensory properties of soy-sorghum-roselle complementary food. British Journal of Applied Science and Technology 6:635-643. |

|

|

Aluko, AE, Kinyuru J, Chove LM, Kahenya P, Owino W (2016). Nutritional quality and functional properties of baobab (Adansonia digitata) pulp from Tanzania. Journal of Food Research 5:23. |

|

|

Amarteifio J, Mosase M (2009). The chemical composition of selected indigenous fruits of Botswana. Journal of Applied Sciences and Environmental Management 10(2). |

|

|

Anilakumar KR, Pal A, Khanum F, Bawa AS (2010). Nutritional, medicinal and industrial uses of sesame (Sesamum indicum L.) seeds - An overview. Agriculturae Conspectus Scientificus 75(4):159-168. |

|

|

Asghar A, Majeed MN, Akhtar MN (2014). A review on the utilization of sesame as functional food. American Journal of Food and Nutrition 4(1):21-34. |

|

|

Asuk AA, Ugwu MN, Idole B (2020). The Effect of Different Malting Periods on the Nutritional Composition of Malted Sorghum-Soy Composite Flour. Journal of Food Science Nutrition and Research 3(3):217-230. |

|

|

Chikuta S, Odong T, Kabi F, Mwala M, Rubaihayo P (2014). Farmers perceptions on dual-purpose sorghum and it's potential in Zambia. International Journal of Agricultural Research, Innovation and Technology 4:76-81. |

|

|

Erhardt J (2007). Nutrisurvey (Version 2007). Available from http://www.nutrisurvey.de |

|

|

FAO/WHO (2001). Human Vitamin and Mineral Requirements. Rome. |

|

|

Folasade M, Makanjuola O (2012). Effect of sesame seed addition on the chemical and sensory qualities of sorghum based kunun- zaki drink. African Journal of Food Science and Technology 3:204-212. |

|

|

Gharby S, Harhar H, Charrouf Z (2015). Chemical characterization and oxidative stability of seeds and oil of sesame grown in Morocco. Journal of the Saudi Society of Agricultural Sciences 16(2):105-111. |

|

|

Hadebe ST, Modi AT, Mabhaudhi T (2017). Drought Tolerance and Water Use of Cereal Crops: A Focus on Sorghum as a Food Security Crop in Sub-Saharan Africa. Journal of Agronomy and Crop Science 203(3):177-191. |

|

|

Hegde DM (2012). Sesame, in: Handbook of Herbs and Spices: Second Edition. Woodhead Publishing Limited pp. 449-486. |

|

|

Hiremath S, Patil C, Patil K, Nagasampige M (2010). Genetic diversity of seed lipid content and fatty acid composition in some species of Sesamum L. (Pedaliaceae). African Journal of Biotechnology 6(5):539-543. |

|

|

Hwang LS, (2005). Sesame Oil, Bailey's Industrial Oil and Fat Products. John Wiley & Sons Inc. pp. 537-575. |

|

|

Inyang UE, Ekanem JO (1996). Effect of dehulling methods and desolventizing temperatures on proximate composition and some functional properties of sesame (Sesamum indicum L.) seed flour. Journal of the American Oil Chemists' Society 73(9):1133-1136. |

|

|

Jeewon TB, Rajesh J (2016). Changes in eating habits and food traditions of Indo-Mauritians. Indian Journal of Traditional Knowledge 15(3):355-362. |

|

|

Kince T, Galoburda R, Klava D, Tomsone L, Senhofa S, Straumite E, Kerch G, Kronberga A, Sturite I, Kunkulberga D, Blija A (2017). Breakfast cereals with germinated cereal flakes: changes in selected physical, microbiological, and sensory characteristics during storage. European Food Research and Technology 243(9):1497-1506. |

|

|

Koitilio B, Kinyua M, Kiplagat O, Pkania K, Chepkoech E, Kimno S (2018). Morphological Characterization of Selected Sesame (Sesamum Indicum L.) Genotypes in Western Kenya. African Journal of Education, Science and Technol0gy 4(4):120-134. |

|

|

Lawal SO, Idowu AO, Malomo SA, Badejo AA, Fagbemi TN (2019). Effect of toasting on the chemical composition, functional and antioxidative properties of full fat and defatted sesame (Sesamum indicum L.) seed flours. Journal of Culinary Science and Technology 19(1):18-34. |

|

|

Mohapatra D, Patel AS, Kar A, Deshpande SS, Tripathi MK (2019). Effect of different processing conditions on proximate composition, anti-oxidants, anti-nutrients and amino acid profile of grain sorghum. Food Chemistry 271:129-135. |

|

|

Momanyi D, Owino W, Makokha A (2020). Formulation, nutritional and sensory evaluation of baobab based ready-to-eat sorghum and cowpea blend snack bars. Scientific African 7:e00215. |

|

|

Msheliza EA, Ilesanmi JOY, Hussein JB, Nkama I (2018). Effect of pretreatments on the microbial and sensory quality of weaning food produced from blends of sorghum and soybean. African Journal of Food Science 12(12):353-359. |

|

|

Mugula JK, Lyimo M (2000). Evaluation of the nutritional quality and acceptability of sorghum-based tempe as potential weaning foods in Tanzania. International Journal of Food Science and Nutrition 51(4):269-277. |

|

|

Muthai KU, Karori MS, Muchugi A, Indieka AS, Dembele C, Mng'omba S, Jamnadass R (2017). Nutritional variation in baobab (Adansonia digitata L.) fruit pulp and seeds based on Africa geographical regions. Food Science and Nutrition 5(6):1116-1129. |

|

|

Nkhata SG, Ayua E, Kamau EH, Shingiro JB (2018). Fermentation and germination improve nutritional value of cereals and legumes through activation of endogenous enzymes. Food Science and Nutrition 6(8):2446-2458. |

|

|

Nyongesa BO, Were BA, Gudu S, Dangasuk OG, Onkware AO (2013). Genetic diversity in cultivated sesame (Sesamum indicum L.) and related wild species in East Africa. Journal of Crop Science and Biotechnology 16(1):9-15. |

|

|

Ogbonna AC, Abuajah CI, Ide EO, Udofia US (2012). Effect of malting conditions on the nutritional and anti-nutritional factors of sorghum grist. The Annals of the University Dunarea de Jos of Galati, Fascicle VI Food Technology 36(2):64-72. |

|

|

Onsaard E (2012). Sesame proteins. International Food Research Journal 19(4):1287-1295. |

|

|

Onyango C, Mutungi C, Unbehend G, Lindhauer MG (2011). Modification of gluten-free sorghum batter and bread using maize, potato, cassava or rice starch. LWT - Food Science and Technology 44(3):681-686. |

|

|

Onyango CA, Ochanda SO, Mwasaru MA, Ochieng JK, Mathooko FM, Kinyuru JN (2013). Effects of malting and fermentation on anti-nutrient reduction and protein digestibility of red sorghum, white sorghum and pearl millet. Journal of Food Research 2(1):41-49. |

|

|

Orr A (2017). Smallholder Value Chains as Complex Adaptive Systems?: A Conceptual framework. Series Paper Number 36. |

|

|

Oyeleke GO, Salam MA, Adetoro RO (2012). Some Aspects of Nutrient Analysis of Seed, Pulp and Oil of Baobab (Adansonia digitata L.). IOSR Journal of Environmental Science, Toxicology and Food Technology 1(4):32-35. |

|

|

Palma MNN, Rocha GC, Valadares FSC, Detmann E (2015). Evaluation of acid digestion procedures to estimate mineral contents in materials from animal trials. Asian-Australasian Journal of Animal Sciences 28(11):1624-1628. |

|

|

Pelembe LAM, Erasmus C, Taylor JRN (2002). Development of a protein-rich composite sorghum - Cowpea instant porridge by extrusion cooking process. LWT - Food Science and Technology 5(2):120-127. |

|

|

Popkin BM (1999). Urbanization, lifestyle changes and the nutrition transition. World Development 27(11):1905-1916. |

|

|

Popkin BM (2015). Nutrition Transition and the Global Diabetes Epidemic. Current Diabetes Report 15(9):1-8. |

|

|

Preichardt LD, Vendruscolo CT, Gularte MA, Moreira ADS (2011). The role of xanthan gum in the quality of gluten free cakes: Improved bakery products for coeliac patients. International Journal of Food Science and Technology 46(12):2591-2597. |

|

|

Ratnavathi CV (2016). Sorghum Processing and Utilization, in: Sorghum Biochemistry: An Industrial Perspective. Elsevier Incorporated. pp. 311-327. |

|

|

Serna-saldivar SO, Espinosa-ram?rez J, Leo N (2019). Grain structure and Grain Chemical Composition, in: Sorghum and Millets. AACC International Press pp. 85-129. |

|

|

Shittu TA, Aminu RA, Abulude EO (2009). Functional effects of xanthan gum on composite cassava-wheat dough and bread. Food Hydrocolloids 23(8):2254-2260. |

|

|

Stefoska-needham A, Beck EJ, Johnson SK (2015). Sorghum?: An Underutilized Cereal Whole Grain with the Potential Sorghum?: An Underutilized Cereal Whole Grain with the Potential to Assist in the Prevention of Chronic Disease. Food Reviews International 31(4):401-437. |

|

|

Tamilselvan T, Kushwaha A (2020). Effect of Traditional Processing Methods on the Nutritional Composition of Sorghum (Sorghum bicolour L. Moench) Flour. European Journal of Nutrition and Food Safety pp. 69-77. |

|

|

Taylor JRN, Taylor J (2017). Proteins from sorghum and millets. In Sustainable Protein Sources. Elsevier Incorporated, pp. 79-104. |

|

|

Taylor JRN, Kruger J (2019). Sorghum and Millets: Food and Beverage Nutritional Attributes. In Sorghum and Millets. AACCI International Press pp. 171-224. |

|

|

Tenyang N, Ponka R, Tiencheu B, Djikeng FT, Azmeera T, Karuna MSL, Prasad RBN, Womeni HM (2017). Effects of boiling and roasting on proximate composition, lipid oxidation, fatty acid profile and mineral content of two sesame varieties commercialized and consumed in Far-North Region of Cameroon. Food Chemistry 221:1308-1316. |

|

|

USDA and HHS (2015). Dietary Guidelines for Americans, 8th edition. U.S. Government Printing Office. |

|

|

Zahrau B, Mohammed AS, Ghazali HM, Karim R (2014). Baobab tree (Adansonia digitata L) parts: Nutrition, applications in food and uses in ethno-medicine - a review. Annals of Nutritional Disorders and Therapy 1(3):1011. |

|

Copyright © 2024 Author(s) retain the copyright of this article.

This article is published under the terms of the Creative Commons Attribution License 4.0