ABSTRACT

Pepper oil sauce or ‘rayu’, is one of the most famous traditional condiments in Korea, Japan and China. Generally, it is prepared using edible oil from soybean, corn among others. Since perilla possesses high amount of omega-3 polyunsaturated fatty acids, the objective of the present study was to investigate the quality characteristics of pepper oil sauces prepared using perilla oil. The quality characteristics of perilla sauces (ONP: onion pepper oil, OIP: oil cake pepper oil and SHP: shrimp pepper oil) were compared with those of the commercially available sauce in Korea (KPO). Carbohydrate and sugar contents and calorie and peroxide values of commercial sauce were higher than those of the perilla oil sauces. However, crude protein and fat were higher in the perilla oil sauces. Soluble solid content of perilla oil sauces was significantly high as compared to that of KPO. The sauce prepared from perilla oil was found to be 12 times higher in omega-3 polyunsaturated fatty acid and 25%less in sodium than a commercial pepper oil sauce. Moreover, the sensory characteristics in terms of overall acceptability of OIP and SHP were also higher than that of the KPO. Results of the present study offer a good choice for production of high value perilla sauce.

Key words: Omega-3 fatty acid, pepper oil sauce, perilla oil, perilla sauce, rayu.

Condiments stand as one of the significant traditional foods of Korea. Pepper oil or hot pepper oil, also known as pepper oil sauce or ‘rayu’, is one of the most famous traditional condiments in Japan, China and Korea. It is a condiment made of vegetable oil that has been infused with chili peppers and used as an ingredient in cooked dishes. It is sometimes used as a dip for meat and also employed in the Korean Chinese noodle soup dish, jjamppong. In addition, it serves as enhancer of flavour and colour to the cuisine and a good appetizer. The sauces increase the nutritional value of the dishes as well as help in digestion (Kim, 2004; Kim et al., 2002).People are becoming more conscious about the health benefit of functional foods (Kapsak et al., 2011). With this change in the food habits of the people, the food industries are likewise giving high priority to production of variety of healthy foods containing functional materials (Yoon et al., 2007; Kapsak et al., 2011). Every year, different products of pepper oil sauce are being launched on the market. Different ingredients are being used to enhance the nutritional values and organoleptic properties of condiments like pepper oil sauce. Quality of pepper oil sauce is mostly affected by the quality of pepper and other factors including the ingredients used (Li et al., 2007).Perilla (Perilla frutescens) is widely cultivated in Korea as vegetable oil crop. It contains 50 to 60% of ω-3 polyunsaturated fatty acid in the form of α-linolenic acid (Narisawa et al., 1994). The α-linolenic acid, a primary fatty acid in perilla oil, is attracting attention as it is believed to have many health benefits such as lowering blood pressure, thrombosis improvement, inhibition of cancer cell proliferation, and retinal and brain development (Lee, 1990). In another report, the quality of tomato sauce increased while the microbial activity was inhibited with the use of perilla leaf (Kim et al., 2013). In general, pepper oil sauces are prepared using different sources of edible oils like those from soybean and corn. Perilla is widely used for flavoring, food, medicine and oil in China, Korea and Japan (Lee et al., 2002). To the best of the authors’ knowledge, perilla oil was not found to have use in making pepper oil sauces so far. Since the perilla is widely cultivated in Korea (Narisawa et al., 1994) and possesses many health benefits, the objective of the present study was to prepare a pepper oil sauce using perilla oil and investigate the physicochemical and sensory characteristics of the sauce in comparison with the commercially available pepper oil sauce.

All the food ingredients were purchased from a retail store in Gyeongju, Korea. Formula of various materials used for preparing different types of sauce samples are shown in Table 1. The optimum amount of perilla oil and other ingredients (Table 1) used in preparing the perilla oil sauces were determined on the basis of their overall taste. The commercially available pepper oil sauce (KPO) was obtained from retail store in Gyeongju, Korea. The KPO was prepared using corn oil.

Sample preparation

The pepper oil sauce samples were prepared following Son (2004) and Koo and Kim (2004) with some modifications. The ingredients (Table 1) were added to the perilla oil heated to 110°C and thoroughly mixed. Three different perilla oil sauce samples: onion pepper oil (ONP), oil cake pepper oil (OIP) and shrimp pepper oil (SHP) were prepared separately. The pepper oil sauce samples were packaged in air-tight container and stored at refrigeration temperature (4°C) until needed for analysis. All the chemicals and reagents used in the present study were of analytical food grade.

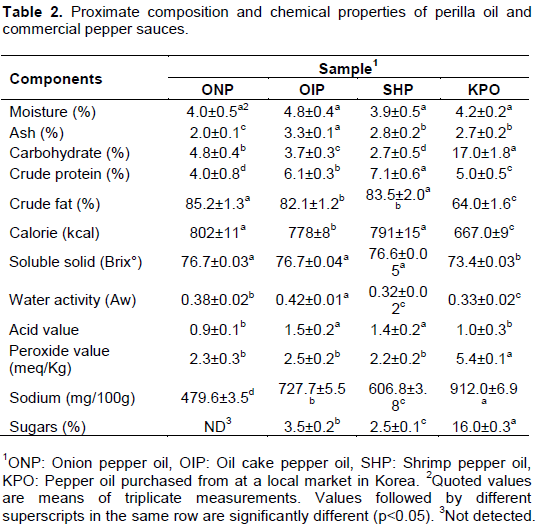

Proximate composition and chemical properties

Contents of moisture, crude protein, crude lipid, ash, carbohydrate and sugar were evaluated according to AOAC (1995). Acid and peroxide values and fatty acid composition were determined following Eltayeib and Elaziz (2014) with some modifications. Calorie value was determined using bomb calorimeter (Parr Instrument Co., Moline, IL, USA). Soluble solid content expressed as degree Brix was determined by a hand refractometer (RX-5000α, Atago, Tokyo, Japan). The water activity was determined at 25°C using a CX–1 chilled-mirror dew-point water activity meter, Campbell Scientific, Ltd. (CX–1 water activity system: Instruction manual: Version 1/3.88).

Crude protein

Sauce sample (0.8 g) was underwent combustion in pure oxygen at 850°C. The amount of nitrogen was measured by thermal conductivity. Crude protein was calculated by multiplying the nitrogen value by 6.25.

Crude lipid

Sauce sample (2 g) was kept into a soxhlet extraction thimble and extracted for 8 h with a constant boiling range (40-60°C) hydrocarbon solvent. The hydrocarbon solvent was removed and the amount of oil was determined gravimetrically.

Ash and moisture content

The ash content was determined by incineration in a muffle furnace at 520°C. The moisture content of the sample was calculated based on weight loss after the sample was heated in an oven at 105°C.

Sugar and carbohydrate

The free sugars and carbohydrates in the extracts are examined using HPLC. The method was based on chromatographic separation of sugars and their retention time. The identification of sugars was done by comparing retention times of individual sugars in the reference vs. tested solution (qualitative analysis). The quantitative assays were made by the following carbohydrates: fructose, glucose, sucrose and maltose. Carbohydrates are separated on the basis of their differential adsorption characteristics by passing the solution to be analyzed through a column. Carbohydrates can be separated on the basis of their partition coefficients, polarities or sizes, depending on the type of column used.

Acid value

Three grams of the cooled oil sample was weighed in a 250 ml conical flask, 100 ml of freshly neutralized hot ethyl alcohol and 1 ml of phenolphthalein indicator solution were added, the mixture was boiled for 5 min, titrated while hot against standard alkali solution and shaken vigorously during titration. Acid value was calculated as follows:

Acid value = (56.1)V.N/W

where, V = volume in ml of standard potassium hydroxide; N= normality of the potassium hydroxide solution; W = weight in g of the sample.

Peroxide value

Five grams of the sample sauce were placed in 250 ml conical flask and fitted with ground-glass stopper. Thirty milliliter of a mixture of chloroform and glacial acetic acid (2:3 v/v) was placed in the conical flask, shake for a minute to dissolve the oil, 0.5 ml of saturated potassium iodide solution and 30 of water were added. The flask content was titrated with 0.01 N sodium thiosulphate, the titrant was added slowly with continuous vigorous shaking until the yellow colour was unchanged and a blank test under the same condition was carried. Peroxide value was calculated as:

Peroxide value = 10 (n1- n2)/m

where, n1 = volume in ml of standard sodium thiosulphate solution required for the sample; n2 = volume in ml of standard sodium thiosulphate solution required for the blank; m = weight of sample

Sodium content

Sodium content was analyzed as described by Ehling et al. (2010) with some modifications. An Activa instrument (Horiba Jobin Yvon, Longjumeau, France) equipped with an autosampler AS500 (Horiba Jobin Yvon, Longjumeau, France), a tangential nebulizer (Miramist Peek Body), a cyclonic spray chamber, a radial torch, a Czerny-Turner monochromator, and an optical path purged with nitrogen was used. The daily calibration of the monochromator was performed by using the carbon emission lines and each operating wavelength was individually centered before the experiment began. Three wavelengths were chosen for Na analysis: 330.237, 588.995 and 589.592 nm. Samples were quantified with ICP-AES three times, first with external calibration of the 1/50 sample dilution, and then with the standard added procedure on the 1/50 sample dilution and 1/100 sample dilution.

Fatty acid composition

The fatty acid composition as fatty acid methyl esters (FAMEs) of the sauces was determined using gas chromatography (GC) following procedures described by Giacometti et al. (2002) with some modifications. Methylation was done with sodium methylate according to the European Union Commission modified Regulation EEC 2568/91. A chromatographic analysis (SHIMADZU set 17 A Series II gas chromatography) was performed using a capillary column (Stabilwax column, Restek Corporation, PA, USA). The column temperature was isothermal at 180°C and the injector at 230°C and detector temperature was 250°C. Fatty acids were identified by comparing retention times with standard compounds.

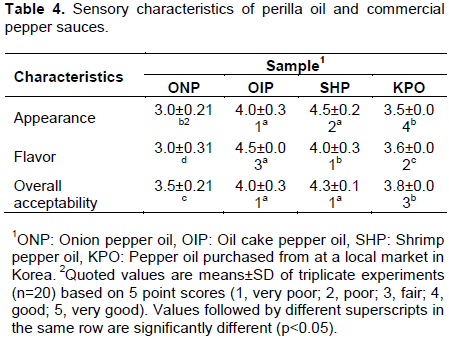

Sensory characteristics analysis

Analysis of sensory properties was performed using freshly made sauce. The aspects rated were for colour, flavour, and overall acceptability using scale (Mugisha et al., 2009) of 1 = very poor, 2 = poor, 3 = fair, 4 = good, and 5 = very good. All the sensory properties were evaluated by 20 semi trained volunteer panelists (10 women and 10 men) selected from the list of graduate students of College of Agriculture and Life Science of Kyungpook National University, Deagu, Korea. Mean values of 20 evaluations for each sensory property were reported as scores.

Statistical analysis

Data were subjected to analysis of variance (ANOVA) using SAS 9.4 (2013). Differences between means at p < 0.05 were analyzed using Tukey test.

Proximate composition of sauces

The values of some of the proximate compositions were significantly different (p < 0.05) among the pepper oil sauces while others were not (Table 2). Moisture content of the KPO was not significantly different from all the other samples. Ash content of OIP was significantly high followed by SHP then KPO. The high value of ash in OIP might be due to the oil cake, which reported to contain high ash (Sharma, 2013) as compared to onion (Yahaya et al., 2010) and shrimp (Brasileiro et al., 2012). Carbohydrate content was significantly high in the KPO as compared to other samples. This might be due to higher carbohydrate containing ingredients in the commercially available pepper oil sauce. Crude protein content of SHP was high as compared to all the other samples. This might be due to higher protein content in shrimp (Brasileiro et al., 2012) as compared to perilla (Gwari et al., 2014) and onion (Yahaya et al., 2010). Crude fat content of KPO was lower than the other three samples made using perilla oil. The calorie content of perilla oil sauce samples were higher than that obtained from the market. This might be due to higher fat content (DeClerck, 2016) of perilla oil containing sauces.

Chemical properties of sauces

The average soluble solids content in perilla oil sauces was higher than that of commercial sauce (Table 2). Measurements of soluble solids by a refractometer could be used to estimate the degree of protein hydrolysis during fermentation (Lopetcharat and Park, 2002).

Water activity (Aw) of OIP was the highest followed by ONP, KPO and SHP, respectively. Aw has been recognized as one of the primary factors influencing the thermal resistance of pathogens in low-moisture foods (Syamaladevi et al., 2016).

Acid value of the KPO was 1.0 which was in the range of perilla oil containing sauce (0.9 to 1.5). The acid value is an indicator of the aged food (Pennington and Hepburn, 1910) or whether the oil has been degraded or become rancid. The peroxide value of the samples corresponded with that of the acid value with the lowest for ONP. The acid and peroxide values are indicator of rancidity behaviour of the oils when properly stored in a container free from atmospheric oxygen and other contaminants (Ogungbenle, 2003). Sodium content of the KPO was about 25% higher than those of three perilla sauces. Excess sodium intake has negative effect on health (He and MacGregor, 2009) causing ventricular hypertrophy as well as fibrosis in the heart, kidneys and arteries (Frohlich, 2007). Sugar content of commercially available perilla oil sauce was significantly high as compared to perilla oil sauces. This might be due to high sugar containing ingredients in the commercially available pepper oil sauce.

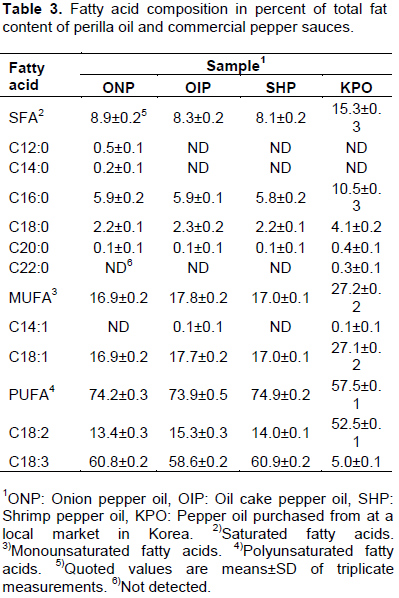

Fatty acid composition of sauces

The fatty acid composition of perilla oil and commercial pepper oil sauces were significantly different (Table 3). The KPO contained higher amount of saturated fatty acids (SFA) and monounsaturated fatty acids (MUFA) but lower amount of polyunsaturated fatty acids (PUFA). In contrast, the perilla pepper oil sauces showed opposite results with highest value for PUFA of the total fatty acids (FAs). The dominant fatty acids in the perilla oil and commercial sauces were α-linolenic acid (C18:3 or omega-3) and linoleic acid (C18:2 omega-6), respectively. The perilla oil sauces contained almost 12 times higher omega-3 PUFA than that of KPO. The higher amount of PUFA in the perilla sauces was attributed to the presence of high α-linolenic acid (C18:3) content in perilla oil (Gwari et al., 2014). It is well stablished that omega-3 PUFA α-linolenic acid (C18:3) reduces cholesterol level (glyceride contents) in human blood as well as to inhibit colon cancer (Narisawa et al., 1994). The α-linolenic acid also has health benefits such as of lowering blood pressure, thrombosis improvement and retinal and brain development (Lee, 1990). The omega-3 fatty acids are mainly consumed by vegans for heart health (Calder, 2004). The results of the fatty acid composition indicate that pepper oil sauces prepared with the perilla oil could be a good option to enhance the value of the sauces with increased health benefits.

Sensory characteristics of sauces

Appearance value of two of the three perilla sauces was higher than that of the commercial sauce (Table 4). Values for OIP and SHP were significantly high as compared to ONP and KPO. The appearance value is not the only criteria for acceptance or rejection of pepper oil sauce unless it is noticeably unusual. Appearance could vary based on types and quantity of ingredients added during preparation (Ogundele et al., 2015). The proportion of ingredients in pepper oil sauce could be varied in accordance with the preference of the individual without severely affecting its originality.

Flavour value was also high for the samples which had higher colour value (Table 4). This might be because of the influence of an ingredient for both colour and flavour. OIP had the highest flavor value followed by SHP, KPO and ONP. Although, different sensory inputs like visual, olfactory, gustatory, tactile, or trigeminal are considered during food consumption (Prescott, 2004), the interaction between taste and odour, which jointly constitute the flavour value, is one of the decisive factors for food evaluation (Delwiche, 2004).

Overall acceptability determines the general acceptance of the product considering all the discriminating sensory characteristics of the sample. Overall acceptability of OIP and SHP was significantly high as compared to other two samples. The ONP showed the least overall acceptability value out of the four samples (Table 4). The reason behind this might be the lower colour and flavour score for ONP that contained high amount of onion (Table 1). Although consumers are truly conscious about the nutritional characteristics (Bruhn et al., 1992), safety (Wilcock et al., 2004), and even the trademark (Guerrero et al., 2000) or price (Caporale et al., 2001) of the product, their benefits cannot outweigh the sensory properties of foods (Siró et al., 2008). The results of the sensory evaluation showed that pepper oil sauces prepared with the perilla oil could be a good option for high value sauce with increased organoleptic properties.

The pepper oil sauce prepared from perilla oil was found to be of superior quality in terms of nutritional value and overall acceptability. Perilla oil sauces contained about 12 times higher omega-3 polyunsaturated fatty acid content and 25% less sodium content than a commercially available pepper oil sauce. Moreover, the sensory characteristics in terms of overall acceptability of OIP and SHP were also higher than that of the commercial product. Results of the present study offer a good choice for production of high value perilla sauce.

The authors declare no conflict of interest.

REFERENCES

|

AOAC (1995). Official methods of analysis of AOAC Intl. 16th ed. Arlington, VA, USA.

|

|

|

|

Brasileiro OL, Cavalheiro JMO, Prado JPDS, Anjos AGD, Cavalheiri TTB (2012). Determination of the chemical composition and functional properties of shrimp waste protein concentrate and lyophilized flour. Cienc. Agrotec. 36:189-194.

Crossref

|

|

|

|

Bruhn CM, Cotter A, Diaz-Knauf K, Sutherlin J, West E, Wightman N, Williamson E, Yaffee M (1992). Consumer attitudes and market potential for foods using fat substitutes. J. Dairy Sci. 75:2569-2577.

Crossref

|

|

|

|

Calder PC (2004). ω-3 fatty acids and cardiovascular disease: evidence explained and mechanism explored. Clin. Sci. 107:1-11.

Crossref

|

|

|

|

Caporale G, Monteleone E (2001). Effect of expectations induced by information on origin and its guarantee on the acceptability of a traditional food: olive oil. Sci. Aliments 21:243-254.

Crossref

|

|

|

|

DeClerck YA (2016). Fat, calories, and cancer. Cancer Res. 76:509-510.

Crossref

|

|

|

|

Delwiche J (2004). The impact of perceptual interactions on perceived flavor. Food Qual. Prefer. 15:137-146.

Crossref

|

|

|

|

Ehling S, Tefera S, Earl R, Cole S (2010). Comparison of analytical methods to determine sodium content of low-sodium foods. J. AOAC Int. 93:628-637.

|

|

|

|

Eltayeib AA, Elaziz AA (2014). Physicochemical properties of Roselle (Hibiscus sabdariffa L.) seeds oil (Elrahad-1) in North Kordofan, Sudan. J. Sci. Innov. Res. 3:578-582.

|

|

|

|

Frohlich ED (2007). The salt conundrum a hypothesis. Hypertens. 50:161-166.

Crossref

|

|

|

|

Giacometti J, Milošević A, Milin C (2002). Gas chromatographic determination of fatty acids contained in different lipid classes after their separation by solid-phase extraction. J. Chromatogr. A 976:47-54.

Crossref

|

|

|

|

Guerrero L, Colomer Y, Guardia MD, Xicola J, Clotet R (2000). Consumer attitude towards store brands. Food Qual. Prefer. 11:387-395.

Crossref

|

|

|

|

Gwari G, Lohani H, Haider SZ, Bhandari U, Chauhan N, Rawat DS (2014). Fatty acid and nutrient composition of perilla (Perilla frutescens L.) accessions collected from Uttarakhand. Int. J. Phytopharmacol. 5:379-382.

|

|

|

|

He FJ, MacGregor GA (2009). A comprehensive review on salt and health and current experience of worldwide salt reduction programmes. J. Hum. Hypertens. 23:363-384.

Crossref

|

|

|

|

Kapsak WR, Rahavi EB, Childs NM, White C (2011). Functional foods: consumer attitudes, perceptions, and behaviors in a growing market. J. Am. Diet Assoc. 111:804-810.

Crossref

|

|

|

|

Kim HD (2004). The total acid, free amino acids contents and sensory characteristics of demi-glace sauce based on omija added quality. J. Korean Soc. Food Cult. 19:348-358.

|

|

|

|

Kim HD, Lee YJ, Han JS (2002). An evaluation of the recognition, preference and quality factors on sauces. J. East Asian Soc. Dietary Life 12:197-209.

|

|

|

|

Kim SH, Kong SG, Park DS (2013). Quality characteristics and sensory evaluation of tomato sauce with added perilla leaf. Korean J. Food Nutr. 26:766-771.

Crossref

|

|

|

|

Koo B-S, Kim D-S (2004). Development of the seasoning oil for replacing red pepper seed oil: manufacturing of red pepper seasoning oil. Korean J. Food Preserv. 11:142-147.

|

|

|

|

Lee YJ (1990). Problems and improvement of maintaining nutrition. Food Sci. Ind. 23:13-30.

|

|

|

|

Lee JK, Nitta M, Kim NS, Park CH, Yoon KM, Shin YB, Ohnishi O (2002). Genetic diversity of perilla and related weedy types in Korea determined by AFLP analyses. Crop Sci. 42:2161-2166.

Crossref

|

|

|

|

Li C-W (2007). Study on the technology of pepper's product mixed edible oil [J]. China Condiment 11:011.

|

|

|

|

Lopetcharat K, Park JW (2002). Characteristics of fish sauce made from pacific whiting and surimi byâ€products during fermentation stage. J. Food Sci. 67:511-516.

Crossref

|

|

|

|

Mugisha J, Akankwasa K, Tushemereirwe W, Ragama P (2009). Urban consumer willingness to pay for introduced dessert bananas in Uganda. Afr. Crop Sci. J. 16:251-258.

|

|

|

|

Narisawa T, Fukaura Y, Yazawa K, Ishikawa C, Isoda Y, Nishizawa Y (1994). Colon cancer prevention with a small amount of dietary perilla oil high in alphaâ€linolenic acid in an animal model. Cancer 73:2069-2075.

Crossref

|

|

|

|

Ogundele GF, Ojubanire BA, Bamidele OP (2015). Proximate composition and organoleptic evaluation of cowpea (Vigna ungiculata) and soybean (Glycine max) blends for the production of Moi-moi and Ekuru (steamed cowpea paste). J. Exp. Biol. Agric. Sci. 3:207-212.

|

|

|

|

Ogungbenle HN (2003). Nutritional evaluation and functional properties of quinoa (Chenopodium quinoa) flour. Int. J. Food Sci. Nutr. 54:153-158.

Crossref

|

|

|

|

Pennington ME, Hepburn JS (1910). The determination of the acid value of crude fat and its application in the detection of aged foods. J. Am. Chem. Soc. 32:568-572.

Crossref

|

|

|

|

Prescott J (2004). Psycological processes in flavour perception. In: Flavor Perception. Taylor AJ, Roberts DD, eds. Blackwell, Oxford, UK, pp. 256-277.

Crossref

|

|

|

|

SAS (2013). SAS User's Guide. Statistical Analysis Systems Institute, Cary, NC, USA.

|

|

|

|

Sharma NK (2013). Chemical composition of oilseed cakes and deoiled cakes in Nepal. Online J. Anim. Feed Res. 3:74-76.

|

|

|

|

Siró I, Kàpolna E, Kàpolna B, Lugasi A (2008). Functional food. Product development, marketing and consumer acceptance–A review. Appetite 51:456-457.

Crossref

|

|

|

|

Son MH (2004). A study on research & development and quality stability of functional red pepper dressing. Korean J. Culinary Res. 10:107-120.

|

|

|

|

Syamaladevi RM, Tang J, Villaâ€Rojas R, Sablani S, Carter B, Campbell G (2016). Influence of water activity on thermal resistance of microorganisms in lowâ€moisture foods: a review. Compr. Rev. Food Sci. Food Saf. 15:353-370.

Crossref

|

|

|

|

Wilcock A, Pun M, Khanona J, Aung M (2004). Consumer attitudes, knowledge and behaviour: a review of food safety issues. Trends Food Sci. Technol. 15:56-66.

Crossref

|

|

|

|

Yahaya Y, Uauri UAB, Bagudo BU (2010). Study of nutrient content variation in bulb and stalk of onions (Allium cepa) cultivated in Aliero, Aliero, Kebbi State, Nigeria. Niger. J. Basic. Appl. Sci. 18:83-89.

|

|

|

|

Yoon SB, Hwang SY, Chun DS, Kong SK, Kang KO (2007). An investigation of the characteristics of sponge cake with ginseng powder. Korean J. Food Nutr. 20:20-26.

|