ABSTRACT

“Energy efficient rural food processing utilizing renewable energy to improve rural Livelihoods” known as the “RE4Food” project is a three year effort by researchers in Sierra Leone, Ghana, Kenya, South Africa, Germany and the UK, funded by the Engineering and Physical Sciences Research Council (EPSRC). It takes its objectives from the observation by the World Health Organization (WHO) that nearly 60% of the world population is malnourished. Developing countries have high population growth and are increasingly using fossil fuels within their food production systems and it is estimated that 7 to 10 calories of energy are required in the production of 1 calorie of food. The artisanal fishing industry in Sierra Leone is faced with challenges in fish processing due to lack of modern facilities. Fish landings typically exceed local demand and the surplus is smoked; the inefficiency of traditional methods threatens terrestrial and mangrove forests. Our research focused on collecting indigenous technical knowledge, economic and efficiency measurements of energy utilized along the value chain. We report initial findings on use of a passive solar drier which shows that they are unlikely to make a substantial contribution to fish processing in Sierra Leone in the immediate future.

Key words: Fish processing, smoking, renewable energy, solar dryer, fishing.

Fish is nutritious food and it constitutes a reasonable percentage of protein to human diets when processed (Adair, 1976). The principal nutritional constituents of fish are: proteins, lipids, minerals and vitamins such as B2. The importance of fish production in the tropics cannot be over emphasized; it is a source of food and raw materials for our growing factories (Alamu, 1990). Fish production from tropical waters accounts for about 17% of the world's total catch (Eyo, 1999). In Sierra Leone the FAO (2014) estimates a total marine catch of about 206,477 tons from 900 powered and 8,526 unpowered fishing vessels employing just over 70 thousand people directly. Ignoring exports and losses, this equates to about 80 grams/person/day of fresh fish or about 20 grams/day of dried smoked fish, and this 20 grams/day is some where between 65% and 90% of the animal protein consumed (the reported figures are rather variable). Studies carried out in 2011 by the Swedish Institute for Food and Biotechnology (SIK) for the Food and Agriculture Organization of the United Nations (FAO) revealed that, roughly one-third of food produced for human consumption is lost or wasted globally, which amounts to about 1.3 billion tons per year (FAOSTAT, 2010a). A significant percentage of these losses are related to improper and/or untimely drying of foodstuffs (Bassey, 1989; Togrul and Pehlivan, 2004). Losses in the food value chain are approximately 1/3 of the total world yield and are estimated to range from about 15% for cereals up to 50% for fresh fruit and vegetables in some developing countries (Hodges et al., 2010). These losses occur during harvest, processing, storage, transportation and retail and apply to almost all food stuffs. Significant losses are a result of a number of factors which include insufficient drying, inadequate storage, insufficient cooling and poor transport – all of which rely on high levels of energy input. In sub-Saharan Africa, losses are predominantly at the producer end of the food chain and reducing these losses is often beyond the means of individual producers, who are predominantly small scale producers (Anon., 2013). Minimization of losses in the food chain will not only increase the quantity and quality of produce but also reduce energy, water and land use (FAOSTAT, 2010b).

The food and nutritional situation in Sierra Leone is poor but not unique. One of the major causes of wastes is the unavailability of energy in poor rural communities for efficient food processing (freezing, canning, drying etc.). In response to this situation the EPSRC (Engineering and Physical Sciences Research Council) of UK funded the “Energy Efficient Rural Food Processing utilizing renewable Energy to improve Rural Livelihoods” known as RE4Food for three years. The project is coordinated by Newcastle University with partners in South Africa, Sierra Leone, Kenya, Ghana and Germany. Three food-chains are being studied; the processing, preservation and use of maize (Ghana), leafy vegetables (Kenya) and fish (Sierra Leone). In each case the critical link between the use of (renewable) energy and food losses are looked at. In Sierra Leone, the project focuses on the use of renewable energy in the artisanal fishing industry for fish processing. Fish was selected after a multi-criteria assessment using 18 factors including items such as the existing and potential market for the product, current energy efficiency and potential for improvement, impact on women’s workload, etc. From a research perspective fish are particularly interesting because:

(1) There is lack of knowledge and actual data on fishermen’s, fishmongers’ and fish processors’ activities,

(2) Widespread, but unsubstantiated beliefs that fish smoking utilizing wood is a major cause of deforestation, and

(3) Fish forms the major component of high grade protein consumed within Sierra Leone, with an estimated average consumption of smoked marine fish in the order of 18kg/person/year, which compares to a consumption figure for “meat” (beef, mutton, goat, bush meats, chicken, etc.) of less than 2 kg/person/year.

The artisanal fishing industry in Sierra Leone provides not only the cheapest source of protein but also employment for a large number of under-educated young people and substantial revenue for government. As the industry attracts more people, more complex fishing techniques were adopted leading to an increase in the catch rate especially for pelagic species. Our research findings have shown that a typical artisanal fishing boat sets off with only 200 to 300 kilograms of ice and those returning late often have a high proportion of fish in bad condition. Due to the lack of refrigerators and other processing facilities, the preferred preservation is by hot smoking. This mode of fish preservation has been practiced for many years. As the industry became more attractive to investors, the number of boats, total catch rate and demand for fire wood also increased. The need for fire wood for smoking fish is believed to have put pressure on the terrestrial and mangrove forests near fishing communities, increasing both the cost of firewood and accelerating the degradation of remaining forested areas. In the capital city of Freetown, smokers said they can no longer afford to purchase mangrove wood which was traditionally held as the best wood for fish smoking. This has caused some individuals to change from farmers to full-time firewood collectors with attendant impact on the terrestrial environment. Sierra Leone is still predominantly a rural country and agriculture accounts for almost half of the GDP, which in 2008 was approximately 46% (Sannoh, 2010). The country was ranked as “needs improvement” with the score of 34.1 out of 100, marking it as food insecure. The global food security index was produced by the economic intelligence unit (EIU, 2016) and according to this report, Sierra Leone scored the following:

80% of population under global poverty line,

65.4 in nutritional standards,

43.6 in food safety,

36 in sufficiency of food supply,

34.1% Food loss,

30.4 in diet diversification,

29.1 micro nutrient availability,

26.7% had access to portable water,

18.1 in protein quality,

10.2 in agricultural infrastructure.

In the context of our research, the low score for “protein quality” (EIU, 2016), is significant given the high dependence of a large majority of the Sierra Leone population on fish protein. In Sierra Leone, marine fish forms the main source of high quality protein consumed by the people, making it essential to the food security needs of the population. In addressing some of the underlying problems associated with protein quality in the artisanal fishing industry, we have attempted to compare fish processed through the use of traditional fish smoking using wood and those dried using renewable energy (solar dryer) in terms of taste, texture, color, flavor and hardness. In addition, we measured the amount of energy utilized to produce a given quantity of dried fish, and finally conducted an economic valuation of resources used in fish processing.

Description of study area

According to the Fisheries Division of Sierra Leone, there are 58 official fish landing sites along the coast of Sierra Leone, with 19 in Port Loko District, 9 in Kambia, 3 in Western Area, 8 in Moyamba District, and the remaining 19 in both Bonthe and Pujehun districts. Our research activities concentrated on two major fishing communities, Goderich and Tombo in the western area. Goderich is located in the western area rural district of Sierra Leone approximately 8 kilometers to the city center Freetown. It is a coastal community bordered by a number of smaller communities and stretches from the coast to the peninsular mountains, with key livelihood activities including fishing and petty trading. According to results from the national population and housing census of 2004, the community has a population of slightly over 4,221 people and the fishing industry is the main employer. Tombo is also in the western area peninsular and is the largest fish market in the country where fish traders from the provinces come to buy and process fish. It is also as a trans-shipment site for remote fishing communities like Shenge, Plantain islands, etc., as they cannot access large markets centers by road due to poor road networks. Tombo is about twenty-four kilometers from Freetown, and the major livelihood activities are fishing, fish processing and marketing, and petty trading.

Indigenous technical knowledge gathering events

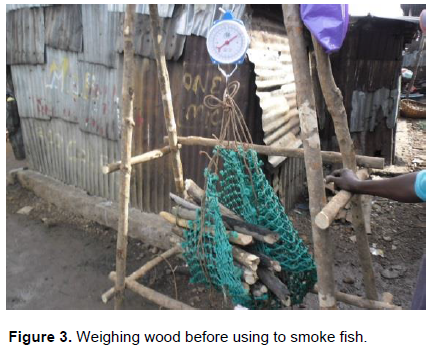

This work focused on fish processing by smoking using potentially renewable energy in the form of firewood as utilized in the artisanal fishing industry. To better understand this, we considered stakeholder’s involvement as a necessity. In this regard, we identified all key stakeholders in the artisanal fishing industry including fishermen, fish processors, fish and wood traders. In a consultative meeting organized with major fishing communities, firsthand information such as, type and sources of energy used in fish processing, causes of fish postharvest losses, and major problems encountered in fish smoking and drying, and possible solutions or alternatives were discussed (Figure 1). Feedbacks from the consultative meeting provided us with a clear picture of challenges encountered by all stakeholders in fish processing (smoking and drying). Apart from stakeholder involvement, experimentation was also adopted in our field research activities. Experimental work involved measurements of fresh and dry weights of fish (Figure 2), quantity of wood used in the smoking for both traditional and improved smokers (Figure 3), and the results obtained were analyzed and subjected to statistical treatment, primarily single factor ANOVA (analysis of variance).

Experiment with solar dryers

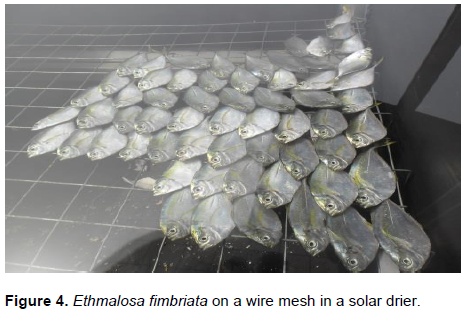

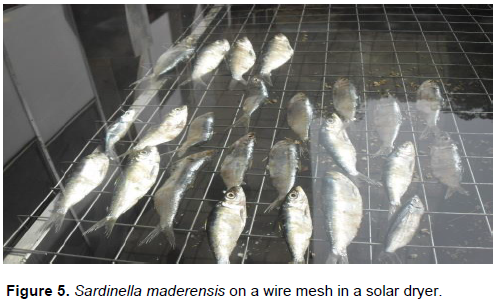

In many parts of the world, there is a growing awareness that renewable energy has an important role to play in extending technology to the farmer in developing countries to increase their productivity (Waewsak et al., 2006). In an attempt to find possible alternatives to the traditional methods of fish drying by smoking, three local solar dryers were constructed. The solar dryers were constructed with plywood of five-ply thickness for the base, and three-ply thickness for the sides and the frames reinforced with 1” × 1” square sections of timber for strength and holding sections of the plywood together.Halfway between the top and the floor of the solar dryer, pieces of 1” × 1” square sections of timber were fitted on the walls of the plywood and across the inside to support a wire mesh to serve as platform for drying the fish (Figures 4 and 5).

In order to determine variations in effectiveness, two of the dryers were covered with transparent plastic sheet and the one with plain glass. On one side of the dryer, an opening was created making it easy for materials to be placed into the box. To enhance emission of moisture from products in the dryer, holes covered with plastic mosquito nets were made into the side of the plywood to prevent flies from entering the dryer. Three such dryers were made and the drying areas (shelf areas) were as follows, 3’ × 2’ (glass top), 4’× 2’ (plastic top) and 6.5’ × 2’ (plastic top). The front edge of each drier is 6” and the back 18”, so that the 6.5’ × 2’ drier is the largest that can be made from a single sheet of plywood (a standard sized sheet of plywood is 8’ × 4’). We also determined the economic value of the solar dryer by calculating the total cost of materials used in construction over the useful days of the dryer per year and the expected life of the device. The weight of the fully constructed solar dryer can be approximated to about 4 kg, making it easy to move it around (Figure 6).

Problems associated with fish smoking and drying in the fishing industry of Sierra Leone

Food drying is a method of

food preservation in which food is dried (dehydrated or desiccated). Drying inhibits the growth of bacteria, yeast, and mold through the removal of water. Fresh fish is a highly perishable food product that requires proper handling and distribution to ensure that it can be utilized in a cost effective and efficient manner. Global demand for fish is growing, and understanding existing handling and marketing channels is essential to maintain reliable supply chains and profitable fisheries sector (Delgado et al., 2003; Williams, 1996

). Research shows that the supply of fresh fish at each fishing harbor is erratic with shortages linked to inability to transport fresh fish; freezer trucks are rare and most harbors lack facilities to make ice. Due to the limited market for fresh fish, much of the catch is preserved by smoking and to a lesser extent sun drying, steaming and frying, the latter two methods are mostly for local consumption, as cooked fish is rarely traded. Fish smoking requires a large quantity of wood, either from terrestrial sources (forests and farm bush) or coastal environments (mangroves). However, a number of challenges are encountered with fish smoking including the scarcity of wood, type of smoking stacks used, and seasonal variations in climatic conditions. Wood used for smoking of fish are harvested from forests, farm bushes and mangrove swamps several miles from Tombo and Goderich, where most of the fishing and fish smoking are done.

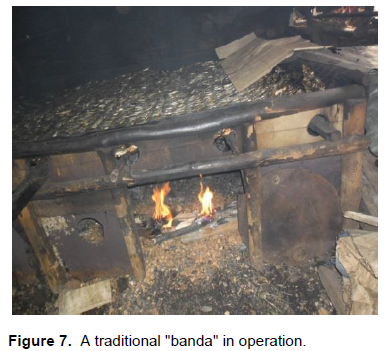

Poor road networks and lack of maintenance of vehicles involved in the transportation of firewood from the interior often lead to scarcity of wood when it is needed. When such scarcity coincides with a large catch, high losses are not uncommon, with economic consequences for the industry. For the smoking of fish, the most common type of smoking stacks used are made locally and often referred to as traditional smoking stacks or ‘banda’. Such stacks are made with metal drums on the sides and iron poles to support the platform structure, with the surface made out of wire mesh for spreading of fish during smoking. Heat retention capacity of such stacks is very low, often requiring large quantities of wood to process the fish. Our observations of commercial smokers show that up to 130kg of wood is burnt to produce 170 kg of smoked “herring” (Clupea harengus). Despite the ease of use and low costs associated with the traditional smoke stacks, they are not energy efficient. The continued use increases the demand for already scarce firewood.

Sierra Leone has a monsoon type climate with a rainy season from May to November and a dry season from December to April, and this has a profound effect on the usefulness of solar dryers. Along the coast, night-time temperatures can be as low as 16°C (60.8°F), and the average daytime temperature is 26°C (78.8°F), sometimes moderated by the harmattan when dry winds blow in from the Sahara Desert. While the use of passive solar dryers for fish drying can be seen as a clean source of energy, they are useful for only about 150 days per year, mostly between the months of December to April and less useful for the rest of the year. Another major challenge associated with fish drying using solar dryers is the length of time it takes to complete a drying cycle; it took approximately five days operating at 7 hours per day to dry 15kg of herring in one of our solar driers. This time duration renders solar dryers less useful in the artisanal fishing industry as most fish processors prefer faster methods that allow them to process fish for the Freetown market in only 2 to 3 h.

Mode of fish smoking and drying

Processing can be defined as a method applied to the product from the time of harvest to the consumption period. Processing of fish into forms for human consumption or suitable to be used as a supplement in animal food has been neglected in fish culture practices. This may be due to the high technology required in some of the processes and the fact that those involved in actual fish production are ignorant of the different processing methods. In other to prevent fish deterioration, every fish processor must strive to employ the best method possible in handing fish to maximize returns on processing investment (Davies, 2005). Fish processing by smoking in Sierra Leone is done in traditional smoking sheds called “banda” and consists of simple construction with a frame about a meter high on which the fish are placed and burning wood placed below the frame. In an “emergency” any type of wood can be used, but under normal condition the preferred species characteristically burn slowly, produce high heat energy, and “sweet” smelling odor from the smoke.

Mangrove wood (Rhizopora mangle and Rhizophora harrisonii) is the most desired, but declining supplies near the capital and increased price have resulted in most processors switching to species such as, Dialium guineense and Sterculia tragacantha from forests and farms. Using a banda, small fish such as herring are placed in rows with stomach facing downwards to ensure the entrails receive enough heat (Figure 7). Species such as “Spanish” are smoked with the aid of a thin stick inserted through the mouth to the tail to enhance easy handling during smoking. Larger species such as barracuda (Sphyraena afra) and sharks (Carcharodon carcharias) are gutted and cut into chunks to enhance heat penetration during smoking. Fish position is often changed during smoking to ensure an effective and even drying process. There are variations on how long the fish is smoked, depending on whether the fish is to be sold locally or transported to distant provincial markets. Fish processors operate independent businesses from fishermen, but some fish processors are also traders/transporters.

Quantitative data collection

We could find little data on fish smoking in the artisanal fishing industry in Sierra Leone, although there are some refereed journal articles from the sub-region e.g. Essumang et al. (2012) on the possible negative effects of PAH contamination with fish smoking; Nti et al. (2002) examined improved fish smoking in Ghana, while Feka and Manzano (2008) discussed the impact of fish smoking on mangrove forests in Cameroon. In Ghana, Lokko and Anson (2002) focused their socio-economic assessment of fishing in coastal communities but noted a paucity of relevant papers on the artisanal fishing industry regionally. Through several consultative meetings, we managed to gain the trust of the fish processors before data collection began. We were partially interested in confirming (or refuting) the ITK (indigenous technical knowledge) supplied by participants at the series of workshops held with them. In the first round of data collection, we concentrated on the process of fish smoking, energy use and food losses in the value chain. For each smoking event, we recorded the species of fish, fresh weight, finished weight, amount and type of wood burnt during smoking and type of banda used. Three types of banda are in use, but our data collection concentrated on the traditional and improved Altona type which were commonly used in the study area (the mud brick type was too rare for statistical comparisons to be made).

Fish smoking

Data was used to confirm and quantify some of the ITK held by the fishing community but we were unable to confirm other aspects. With the data available we were able to test:

(1) Seasonal variability,

(2) Species variability,

(3) Type of “banda” (traditional versus Altona), and

(4) Size of catch (load in the banda).

We were unable to investigate:

(1) The impact of fishing gear (especially use of mono-filament nets as these are illegal),

(2) Quality of fish - we lacked the skill to make an expert judgment, and

(3) Use of mangrove wood versus “forest’ wood, as so few people were using mangrove in these communities.

We measured “efficiency” in two ways:

(1) Loss of weight in catch per unit of wood used - mostly this is water driven off, but could include some wastage such as fish falling into the fire, and

(2) Weight of dried product per unit of wood used (Table 1).

Observations were carried out in May/June (early wet season) and January/February (late dry season). Mean weight loss per kg of wood burnt was:

(3) Dry season = 1.28 kg (n=21)

(4) Wet season = 1.43 kg (n=22)

One-way ANOVA shows these differences are not significantly different (p>0.05, F=0.87, total df=42), nor are the results in accordance with ITK which suggests higher energy use in the wet season. It is possible that our “wet season” observations were too early and in consequence we intend to take more measurements in October at the tail end of the rainy season (when the rainfall in the preceding six months should have totaled about 3 meters).

Species type

We had sufficient observations to assess three species. Mean weight loss per kilogram of wood burnt was:

(1) Herring (Clupea harengus) = 1.00 kg (n=17)

(2) Spanish (Gadus morhua) = 1.35 kg (n=9)

(3) Bonga (Ethmalosa fimbriata) = 1.74 kg (n=14)

One-way ANOVA shows these differences are significantly different p<0.001, (F=7.81, df=39). Herring is an oily fish, and smoked whole, while Spanish is a large fish that is usually cut into pieces before smoking. Bonga is a small thin fish and the most common species found in the markets.

Types of Banda

Traditional and Altona were compared; we had too few observations to include the mud brick banda in the analysis. Mean weight loss per kg of wood burnt was:

(1) Traditional banda = 1.10 kg (n=31)

(2) Improved banda = 2.17 kg (n=9)

One-way ANOVA shows these differences are statistically significantly different at p<0.001, (F=45.7, total df =39). Despite its obvious technical efficiency, the improved banda is not widely used. Further discussion with fish processors revealed that the improved banda required more labor to smoke a load of fish, and this increased cost was greater than the value of the wood saved (at current market prices). The main preference for use made of the improved banda is by traders from the provinces who buy fresh fish and then smoke them to their own specifications, rather than buying already processed fish. Correlation between the size of the load in the banda and the efficiency of the drying process is very low (r=-0.049) and not statistically significant (p>0.05, n=43). Our working assumption is that what is important is whether the banda is filled to some optimal design capacity; too much or too little makes the process much less efficient. Partial confirmation of this is from a comment at the workshop when stakeholders discussed integration of fishing and fish processing businesses. It was perceived as being too difficult, as either the banda was too full or not full enough (so less efficient), or the fisherman stayed out too long trying to get a full banda load and so arrived on shore with lower quality fish.

Solar dryer

Due to the seasonality of usefulness of the solar dryer, only herring and other small pelagic fish were tested in the solar dryer. It took between 24 and 30 h (at 6 h per day) to dry herring so that no more weight loss was possible. Smaller fish (Figure 4) could be dried only slightly faster (Table 2). Result acquired from solar dryer experiment clearly shows the potentials in solar dryer for food processing as an alternative to firewood. Despite a few disadvantages, our observations show that, fish dried in solar dryer have a longer shelf life than smoked fish. Consumer perception on taste of fish dried in the solar dryer during our second round of consultative stakeholder knowledge sharing event showed that, there was only slight difference in taste between fish dried in solar dryer and those dried through wood smoking. Unfortunately, fish dried by smoking is considered to be a bit tastier with pleasant smell due to the presence of smoke aroma.

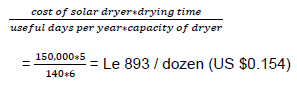

Economics of solar dryers

The approximate cost of building our solar cabinet dryers was Le 150,000 (US $90); this is considerably more than the 1,700 Rupees (US $36) reported by Sengar et al. (2009) for a plastic covered dryer for prawns. The low capital cost comes at the downside of being a fairly fragile construction. For the glass topped drier, there is a risk of breakage and while the plastic top can be mended with tape the UV light and dust spoilt the surface rapidly. The cheapest and thinnest grade plywood was used and this adds to the fragility. Despite the low capital cost of the solar dryers, our findings reveal that, the use of solar dryers still have economic implication when the following factors such as, cost of dryer, useful days of dryer and duration of drying are considered.

The data in Table 3 was used to determine the cost of the dryer per day and as well as the cost of drying.

Cost of drying one dozen herring =

The above analysis excludes labor costs which are modest compared to hot smoking where a fire has to be tended and fish moved about. The cost of smoking herring was observed to be between Le 1,000 to Le 1,500 ($0.259) per dozen for the Freetown market and Le 2,000 to Le 2,500 ($0.431) for the provincial market where fish need to be drier for a longer “shelf-life”. Theoretically the “pay-back” period on saved wood would be between 77 days and 8 years; even in the most optimistic scenario this is longer than Songar et al. (2009) who estimated a pay-back period of about one month when the dryer is used for salted dried prawns. As well as the lower capital costs, the device benefited from being able to dry the prawns in one day rather than the 4 or 5 days we required to dry fin fish. Results from current work on energy used in fish processing shows that, about a quarter of the expenditure goes on firewood. Fish processors are changing their habitats more rapidly than expected, for example it is always said that they prefer mangrove wood, but we found very few people using it. It would seem rational to assume that they will switch to other forms of processing fish as soon as it becomes economically sensible to do so and that they are not hide bound by tradition. However, new technologies need to fit into the available labor supply and be affordable. This is in line with work done by Waewsak, et al. 2006 on mathematical modeling study of hot air drying for some agricultural products in which he stated that, in many parts of the world there is a growing awareness that renewable energy have an important role to play in extending technology to the farmer in developing countries to increase their productivity.

Sierra Leone is not very food secure and access to high quality protein is limited, with most being supplied by the artisanal fishing industry. The challenges of inadequate energy for fish processing faced by the industry has limited the quality and to a lesser extent quantity of fish protein for some parts of the year. In such a situation, measures to increase protein accessibility by using more energy efficient technology need to be encouraged, by taking into account the socio-economic constraints faced by producers and processors. While technically efficient technologies exist to reduce waste, they often require excessive capital or running costs. Our assessment is that simple passive cabinet solar driers are unlikely to make a substantial contribution to fish processing in Sierra Leone in the immediate future because they take too long to dry the fish to an acceptable moisture content and they can only be used for less than half the year.

The authors have not declared any conflict of interests.

REFERENCES

|

Alamu S (1990). Assessment of women contribution to fishing industry and fish marketing in Kainji Lake Basin. Annu. Report 184-190.

|

|

|

|

Anon (2013). Global Food: Waste Not, Want Not, Report by the Institute of Mechanical Engineers. UK

|

|

|

|

Adair D (1976). Handling processing and marketing of tropical fish. Proceedings of the conference on the handling processing and marketing of tropical fish tropical products institute 56162 Gray's Inn Road London WUX 8LU 1977-183.

|

|

|

|

Bassey MW (1989). Development and use of solar drying technologies. Nig. Sol. Energy 89:133-64.

|

|

|

|

Delgado CI, Wada N, Rosegrant MW, Meijer S, Amed M (2003). Outlook for fish 2020. Meeting global demand. A 2020 vision for food, Agriculture and the environment initiative. International food policy research institute, Washington, D. C, Worldfish Center, Penang, Malaysia.

|

|

|

|

Davies RM (2005). Development of Appropriate Technology of fish processing in Nigeria. A paper presented at a one-day workshop on intensive fish farming on Thursday, 24th February. Ibadan, Nigeria

|

|

|

|

EIU (Economist Intelligent Unit) (2016). Global food security index report.

View

|

|

|

|

Eyo AA (1999). The effect of traditional handling, processing and storage methods on the quality dried fish in small scale fisheries in Nigeria in Proceedings of the 13' Annual Conference of fisheries society of Nigeria 50-54.

|

|

|

|

Essumang DK, Dodoo DK, Adjei JK (2012). Polycyclic aromatic hydrocarbon (PAH) contamination in smoke cured fish products. J. Food Comp. Anal. 27:128-138.

Crossref

|

|

|

|

Feka NZ, Manzano MG (2008). The implication of wood exploitation for fish smoking on mangrove ecosystem conservation in the south-west province, Cameroon. J. Trop. Conserv. Sci. 1(3):222-241.

Crossref

|

|

|

|

FAO (2014). FAO Yearbook Fishery and Aquaculture Statistics. Food and Agricultural Organization of the United Nations. Rome.

|

|

|

|

FAOSTAT (2010a). Publications on Statistical Methods and Standards: Crops statistics – Concepts, Definitions and Classifications,

|

|

|

|

FAOSTAT (2010b). Food balance sheet (2007),

|

|

|

|

Hodges RJ, Buzby JC, Bennett B (2010). Postharvest losses and waste in developed and less developed countries: opportunities to improve resource use. J. Agric. Sci. 1-9.

|

|

|

|

Lokko P, Anson S (2002). Baseline studies of some fishing communities in Ghana – a comparative study. Ghana J. Sci. 42:11-18

|

|

|

|

Nti CA, Plahar WA, Larweh PM (2002). Impact of the adoption in Ghana of an improved fish processing technology on household income, health and nutrition. Int. J. Consum. Stud. 26:102-108.

Crossref

|

|

|

|

Sannoh IJ (2010). FAO

|

|

|

|

Sengar SH, Khandetod YP, Mahod AG (2009). Low cost solar dryer for fish. Afr. J. Environ. Sci. Technol. 3(9):265-271.

|

|

|

|

Togrul IT, Pehlivan D (2004). Modelling of thin layer drying kinetics of some fruits under open-air sun drying process. J. Food Eng. 65:413-425.

Crossref

|

|

|

|

Waewsak J, Chindaruksa S, Punlek C (2006). A mathematical modeling study of hot air drying for some agricultural products. Thammasat Int. J. Sci. Technol. 11(1):14-20.

|

|

|

|

Williams M (1996). The transition in the contribution of living aquatic resources to food security. Food, Agricultural and the Environment. International food policy research institute, Washington D. C.

|