ABSTRACT

The study aimed at determining strategies that could be utilized to reduce the concerns of consumers on the processed agricultural products through technology in order to make technological innovation effective and economically rewarding. Two research questions were developed and answered by the study using cross sectional survey research design. The sample for the study was 317 consisting of 116 registered women melon processors, 102 marketers and 98 extension agents. A 24-item well structured questionnaire was developed and used for data collection. The data collected were analyzed using principal component analysis with varimax rotation and factor loading of 0.40. The results showed that the flavour of melon seeds processed mechanically could be enhanced in Southeastern Nigeria through mechanical, maintenance and hygienic factors while that of neatness of melon seeds processed mechanically could be enhanced through hygiene, biological and handling/distributive factors. It was therefore recommended that Agricultural Extension Agents should utilized the identified skills with their corresponding factor loading in melon processing to make women melon processors improve in their processing methods among others.

Key words: Agribusiness concerns, large scale processing, marketing, melon, Southeastern Nigeria.

Agribusiness is an industry that is engaged in the production operation of a farm, the manufacture and distribution of farm equipments, processing, storage and distribution of farm commodities (Merriam, 2015). Food and Agricultural Organization (2015) described agribusiness as the collective business activities that are performed from farm to fork, which covers all the supply of agricultural inputs, the production and transformation of agricultural produce and their distribution to final consumers. Encyclopedia Britannica (2014), reported that in highly industrialized countries, many activities essential to agriculture are carried on separately from the farm. These include the development and production of equipment, fertilizers and seeds. In some countries the processing, storage, preservation and marketing of products have also been separated from basic farming. Farmers who are into crop production are engaged in the production of crops such as maize, cassava, cereals, melon among others. Some other farmers could process, stored and market these crops such as cassava, melon among others into another form before marketing.

Egusi melon (Colocinthis citrullus) is one of the leguminous crops planted mainly in southeastern part of Nigeria. Ojiel et al. (2007) explained that egusi melon originated from West Africa and is a member of the Curcubitaceae family. There are two major varieties of melon favored in West Africa. The round brown seeded melon and the oval white seeded melon. Melon is a creepy annual herb with hairy stems, forked tendrils and three lobed hairy leaves. Brande et al. (2012) stated that melon is a good source of amino acids such as arginine, niacin, tryptophan, and metheonine; vitamins such as vitamins B1 and B2; and minerals such as zinc, iron, potassium, phosphorus, sulphur, manganese, calcium, lead chloride and magnesium. The seed of melon also contains 50 and 30% oil and protein respectively (Brande et al., 2012). Melon fruits are collected when ripe and processed to obtain the seeds for sale or use.

Processing of melon is the manual removal of seeds from melon fruit. Enugu State Agricultural Development Programme (ENADPE) indicated that five hundred and eighty women melon farmers still carry out manual processing of melon. Egunjobi and Adebisi (2004) and Jackson et al. (2013) stated that processing of melon seeds involved fermentation and washing to remove the fermented pod husks (depodding). Depodding and fermentation are carried out simultaneously as the pods are left on the field to rot for three to four days, after which the washing stage starts. This is followed by the drying of the seeds using the open air drying system at the ambient temperature of between 30 and 32°C (mean 31°C) and the relative humidity of 65 to 68% (mean 67%).

Based on the expansion on the growing of melon and the constraints from manual processing, mechanical processing, therefore, becomes necessary to sustain the tempo of melon production and guarantee some conservation of energy for the women processors.

The mechanical processing (shelling) of melon is fast and can produce very large amount of melon seeds (cotyledons) for the market. The processing machines are very expensive to buy, operate and maintain. For example it required a trained operator who will be paid high wages and also technician to repair and service the machine regularly and high cost of electric bills and security of the machine. Despite the high cost of mechanical processing, experience reviled that the market demand of mechanically processed melon by consumers was generally low because the consumers prefer manually processed melon to the mechanically processed melon.

A pilot study conducted by the researchers in a local market in the study area on the issue of rejection of the mechanical processed melon by the consumers reviled that: the flavor of the processed melon has a mixture of other elements other than that of the natural flavor of manually processed melon, the surface of the mechanical processed melon seed are usually coarse, rather than being smooth or nylon in appearance like the manually processed melon, some of the seeds are broken, indicating to the consumers that the nutritive values have been degraded, the natural colour of manual processed seeds have been stored for a long time and become filthy and finally the mechanical processed melon emits some odour of the presence of chemicals which consumers will not like to consume, hence consumers go in search for manually processed melon at a higher cost. Shittu and Ndrika (2012) stated that most of the machines developed for shelling melon are efficient but give high rate of seed damage. Based on these observations, women farmers are withdrawing gradually from the production of melon on commercial basis because of the low income received and the high resource input in terms of human and mechanical efforts.

There is always market for manually shelled (processed) Egusi, even if you bring 30 bags to the market, it will be bought. Enough Egusi is seen in the market from June to July and very cheap while from October to December Egusi is scarce and costly. Van der Vossen et al. (2004) equally stated that about 5,000 to 7,000 metric tonnes (MT) Egusi (melon) seed were exchange between Nigeria and countries in the Economic Community of West African States (ECOWAS) and North Africa.

The purpose of the study therefore, was to determine strategies for improving the processing of melon in order to make it demand-driven to consumers with reference to flavor, brightness, reduction of breakage and improvement in the odour from the machine. If these are achieved, processing of melon mechanically by women farmers will become more cost effective with high rate of returns.

The study adopted cross-sectional survey design. The study was carried out in Southeastern Nigeria, made up of Abia, Anambra Ebony, Enugu and Imo State. South East, Nigeria is naturally endowed with good soil, adequate rainfall, optimal temperature and sunshine for melon production and women in rural areas of this zone are involved in melon production. Therefore, the area is considered very suitable for carrying out the study.

The population for the study was 4850 made up of 580 registered women melon processors, 510 marketers and 490 extension agents. The sample population was 317 consisting of 116 registered women melon processors, 102 marketers and 98 extension agents. Proportionate 20% stratified random sampling technique was used to select the sampling population for the study. Multi-stage sampling technique was used to select two out of five states that make up southeastern Nigeria. Simple random sampling technique was adopted in selecting one agricultural zone in each of the states, thus Enugu and Awka agricultural zones were selected. In each of the zones, simple random sampling technique was employed in selecting 58 registered women melon processors, 51 women marketers and 49 extension agents, respectively.

The instrument used for data collection was twenty-four item structured questionnaire containing skill items generated from review of literature and focus group discussion. The questionnaire was divided into two sections based on strategies for improving the flavor and neatness of melon seed processed mechanically. The response scale for the items was based on the four-point rating scale of strongly agree, agree, disagree and strongly disagree with their corresponding values of 4,3,2,1 respectively. The instrument was face-validated by three experts; two from the Department of Food Science and Technology, University of Nigeria, Nsukka and one from women melon processors in Enugu State. The experts were requested to restructure and correct items that were wrongly written and eliminate all those that were irrelevant. Cronbach Alpha method was used to determine the internal consistency of the instrument. The Cronbach Alpha reliability co-efficient (r) of 0.72 was obtained. The instrument was administered by the researcher with the help of three research assistants.

The data collected were analyzed using exploratory factor analysis to identify strategies for improving the processing and marketing of melon in Southeastern Nigeria. To group the identified strategies, principal component analysis with varimax rotation was adopted with factor loading of 0.40. Therefore, factor loading of less than 0.40 or variables that load in more than one factor were discarded. Only variables with factor loadings of 0.40 and above at 10% overlapping variance (Ashley et al., 2006) were used in naming the factor strategies in this study. The naming of each factor is based on the set of variables or characteristics in the component (Kessler, 2006). The principal component factor analysis model for achieving the objective was given as:

Y1 = a11X1 + a12X2 + * * *+ a1nXn

Y2 = a21X1 + a22X2 + * * * + a2nXn

Y3 = a31X1 + a32X2 + * * * + a3nXn

* = *

* = *

Yn = an1X1 + an2X2 + * * + annXn

Where: Y1, Y2 …Yn = observed variables/strategies for improving the processing and marketing of melon.

a1 – an = factor loadings or correlation coefficients.

X1, X2, … Xn = unobserved underlying factors strategies for enhancing the processing and marketing of melon.

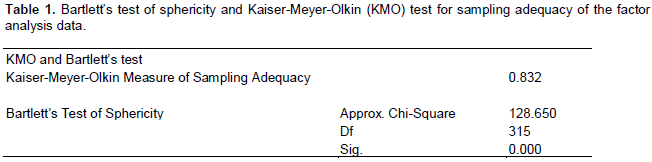

The results of the study were obtained from the research questions answered and are presented in Tables 1 and 2. The result presented in Table 1 shows the Kaiser-Meyer-Olkin (KMO) and Bartlett’s tests for adequacy of the factor analysis data used for the study. From the result, the value of Kaiser-Meyer-Olkin (KMO) measure of sampling adequacy was 0.832. This indicated that, the sampling used for the factor analysis was meritoriously adequate. In affirmation Kaiser (1974) reported that KMO values in the 0.90s as marvelous, in the 0.80's as meritorious while in the 0.70's as middling. On the other hand, the Bartlett's test of sphericity tests the hypothesis that the correlation matrix is an identify matrix. Since, the sig. value (0.000) for this analysis was less than 0.05, there were significant relationships between the specified variables and factor analysis is appropriate.

Research question 1

What are the strategies for improving the flavour of melon seed processed mechanically?

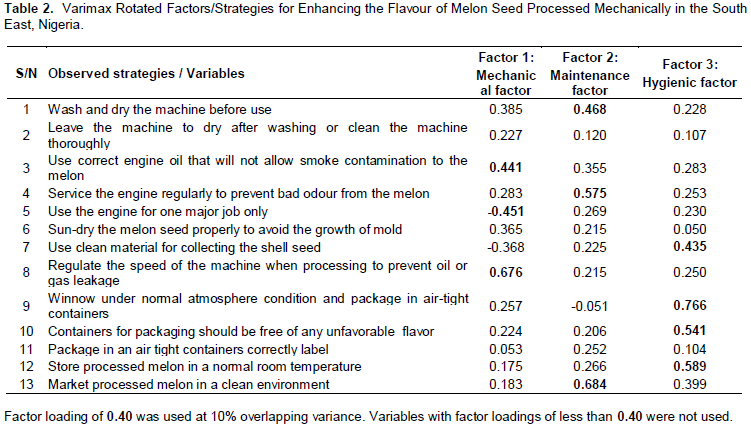

Table 2 presents the varimax-rotated principal component factor analysis of strategic factors for enhancing the flavour of melon seed processed mechanically in Southeastern Nigeria. From the result presented in Table 2, each factor was extracted based on the responses of the respondents. Under factor 1 (Mechanical factor), the specific strategy variables that could be employed for enhancing the flavour of melon seed processed mechanically in southeastern Nigeria included: using correct engine oil that would not allow smoke contamination to the melon (0.441), using the engine for one major job only (-0.451) and regulating the speed of the machine when processing to prevent oil or gas leakage (0.676).

Under factor 2 (Maintenance factor), the identified strategies included: washing and drying the machine before use (0.468), servicing the engine regularly to prevent bad odour from the melon (0.575) and marketing processed melon in a clean environment (0.684) while the specific strategy variables for enhancing the flavor of melon seeds processed mechanically under factor 3 (hygienic factor) included: using clean material for collecting the seed shell (0.435), winnowing under normal atmospheric condition and packaging in air-tight containers (0.766), containers for packaging should be free of any unfavorable flavor (0.541) and storing processed melon in a normal room temperature (0.589).

Research question 2

What are the strategies for improving the neatness of the melon seed processed (shelled) mechanically?

The data presented in Table 3 shows that the strategies for improving the neatness of melon seeds processed mechanically in Southeastern Nigeria. They were grouped into three factors: Factor 1 (Hygienic factor); Factor 2 (Biological factor) and Factor 3 (Handling/distributive factor).

Under factor 1 (Hygienic factor), the specific strategy variables that could be employed for enhancing the neatness of melon seeds processed mechanically in southeastern Nigeria included: processing only ripe pod of melon (0.750), washing melon seeds thoroughly with clean water (0.522), keeping the grinding machine clean to avoid impurities in the processed melon (-0.472) and observing personal hygiene such as wearing apron, covering head and washing hands before processing (0.522).

The identified strategies under factor 2 (Biological factor) included: keeping to the normal fermentation period to prevent over fermentation to avoid germination (0.530), testing for moisture content before processing (0.429) and shelling melon appropriately with the correct machine (0.497) while the specific strategy variables for enhancing the neatness of melon seed processed mechanically under factor 3 (Handling/distributive factor) included: keeping to the washing period to avoid melon seeds soaking water (0.567), winnowing immediately and packaging in an air-tight container for sale (0.423) and market-processed melon in a clean environment (0.660).

The findings of this study on the strategic factors for enhancing the flavor of melon seeds processed mechanically agreed with the findings of Weimer (2007) on improving the flavour of cheese where the author found that mechanical, physical and chemical factors significantly influenced the processing of cheese flavour. In addition, the study also found that milk, salt and other ingredients had positive effects on flavour of processed cheese.

The findings of this study also corroborated with that of FAO (2009) on meat and meat products in human nutrition in developing countries. The findings of the study showed that mechanical refrigeration and hygiene practices were important in processing and improving the flavor of processed meat products. Chilled" meat is hygienic and usually stored at temperatures around 1 to +4°C when it keeps well. Oscar and Parker (2007) claimed that meat could keep for 10 weeks if slaughtered/cut under strict hygienic conditions, packaged using modern packaging techniques and stored in cool (1 to 0°C) environment under carbon dioxide or nitrogen or in a vacuum. The findings of this study on the factors for enhancing the neatness of processed melon supported that of Mahmud (2004) on socioeconomic factors influencing meat value chain in Kano State where the author found that hygiene, neatness and distributive approach were determinants of acceptability of meat products.

In Southeastern Nigeria, the concerns about the use of technology were real. Processed (shelled) melon seeds had poor flavour and the neatness was not guaranteed. Seed moisture content was found to be the main predictor of shelling efficiency while speed uniquely predicts percentage seed damage. Based on the findings of this study, the following recommendations were therefore made:

1). Agricultural extension agents should utilized the identified skills with their corresponding factor loading in melon processing to make women melon processors improve in their processing of melon.

2). The Government through Agricultural Development Programme (ADP) should utilize the findings of this study to organize awareness training programme to all the farmers to enable them improve their processing and marketing strategies of melon seeds.

3). Appropriate machine should be redesigned for the women for more efficiency of processing.

SUGGESTION FOR FURTHER RESEARCH

1). Further research could be replicated in other geopolitical zones in Nigeria.

2). Proficiency improvement needs of Women farmers for effective mechanical processing of melon South Eastern Nigeria.

3). Finding out the training skills required by trainers for helping women farmers to manage their resources in melon production effectively.

The authors have not declared any conflict of interests.

REFERENCES

|

Ashley B, Amber S, Anthony F (2006). Education by Nation: Multivariate analysis.

|

|

|

|

Brande YM, Adam NM, Jamare BO, Azmi Y (2012). Physical and Mechanical Properties of "Egusi Melon Fruit. Int. J. Agric. Res. 7:494-499.

|

|

|

|

|

Egunjobi JK, Adebisi AA (2004). Cumeropsis Mannii PROTA 2i regetable/legumes (CD-Rom) PRO Mageningen Netherlands.

|

|

|

|

|

Encyclopedia Britannica (2014). Agribusiness: Agriculture. Available at:

View.

|

|

|

|

|

Food and Agricultural Organization (FAO) (2009). Meat and meat products in human nutrition in developing countries. Rome.

|

|

|

|

|

Food and Agriculture Organisation (FAO) (2015). Agricultural Development: The Importance of Agribusiness.

|

|

|

|

|

Kaiser HF (1974). An Index of Factorial Simplicity. Psychometrika. 39:31-36

Crossref

|

|

|

|

|

Kessler CA (2006). "Divisive Key–Factors Influencing Farm Households Soil and Water Conservation Investment". J. Appl. Geogr. 26:40-60.

Crossref

|

|

|

|

|

Mahmud TA (2004). Socioeconomic factors influencing meat value chain in Kano State. J Food Sci. 5(3):90-103.

|

|

|

|

|

Merriam Webster (2015). beta.merriam-webster.com/dictionary/agribusiness. Merriam-webster incorporated.

|

|

|

|

|

Ojiel G, Oluba O, Ogunlowo A, Eidangbe G, Orole R (2007). Compositional Studies of Colocynthrus citrullus (Egusi Melon) Seed. The Int. J. Nutr. Wellness 6(1):35-40.

|

|

|

|

|

Oscar AS, Parker K (2007). Physical, chemical and biological changes in foods caused by thermal processing. J. Appl. Sci. 5(3):177-185.

|

|

|

|

|

Shittu SK, Ndrika VO (2012). Development and Performance Tests of a Melon (egusi).

|

|

|

|

|

Van der Vossen HAM, Denton OA, El-Tahir IM (2004). Citrullus lanatus (Thumb); Matsum and Nakai. In: Grubben G.J.H. and Denton O.A. (Eds). Plant Resources of Tropical Africa 2. Vegetables. PROTA Foundation, Wageningen. The Netherlands.

|

|

|

|

|

Weimer BC (2007). Improving the flavour of cheese. University of California, Davis, USA.

Crossref

|

|