ABSTRACT

In sugar cane crop fertigation management systems, about 500 m3 ha-1 of diluted vinasse is applied annually by cycle, promoting nutrient recycling and supply to the soil, especially that of potassium (K). With the increase of sugar cane areas with subsurface drip irrigation, hydraulic characterization related to vinasse intermittent application is important, in order to verify uniformity flow in drippers. The aim of this study was to hydraulically characterize performance and orifice position of different dripline models subjected to intermittent vinasse application, in order to verify flow disorders. The experiment conducted was in a test bench in the Biosystem Engineering Department - ESALQ/USP. The experimental design was completely randomized, with 10 repetitions. Four dripline models (Hydrolite HY 0.65, Hydrolite HY 1.0, Drip Net PC DN 0.6 and Drip Net PC DN 1.6) and 13 consecutive weekly assessment periods were used as treatments. At the same time, dripline orifice position influence (upward and downward) was assessed in two (Hydrolite HY 0.65 and Drip Net PC DN 0.6) of the four dripline models in the respective periods (2x2x13 factorial = Two models, two orifice positions and 13 periods/weeks). Ten drippers from each model were randomly selected, in order to monitor flow. Vinasse application was conducted daily during four hours, with dripline product rest for 20 h, and flow reading at every 168 test h (weekly). HY models (0.65 L h-1) with drippers positioned upwards and downwards, and upwards HY (1.0 L h-1) and DN (1.6 L h-1) showed flow variation coefficient (VC) lower than 5%, which is rated as excellent. The other models showed VC lower than 10%, which was classified as good, enabling vinasse use in the 2:1 concentration in driplines.

Key words: Flow variation coefficient. clogging. fertigation. dripping. potassium. vinasse.

Brazil produced about 27 million cubic meters of ethanol from sugarcane (Saccharun spp) in the 2010/2011 season, generating approximately 337 billion cubic meters of vinasse as a byproduct (Unica, 2012). Sugar cane fertigation with vinasse is used by most plants, as it partly or totally replaces potassium fertilization for crops, providing increases of this nutrient in the soil and in the plant shoot (Brito et al., 2005; Silva et al., 2014). Vinasse fertigation is an economically viable alternative to the producer and a strategic alternative for the country, since 90% of potassium fertilizers are imported (Anda, 2012).

Vinasse is an ethanol distillation byproduct with approximately 97% water. The solid fraction consists mainly of organic matter and minerals, in which potassium (K) is the most abundant, accounting for about 20% of the elements. This element is taken as the limiting factor to define the vinasse dose to be applied per hectare in soils cultivated with sugar cane (Marques, 2006).

Vinasse can replace some of mineral fertilizer nutrients. Its in natura use through fertigation has positive effects on plantation yield and longevity due to sugar production increase per hectare, which is more pronounced as the number of cuts increases (Có Júnior et al., 2008; Barbosa et al., 2013).

Vinasse composition knowledge is important for guidance regarding the dose to be applied in the soil, in order to meet legislative requirements through proper application in agricultural areas. Application cost particularly depends on the system, which should be related to characteristics and needs of each production unit.

In a survey conducted in plants from the state of São Paulo, it was observed that vinasse has large chemical composition variability. However, in general, organic matter amounts were high, followed by potassium, sulfur, calcium, nitrogen, magnesium and phosphorus. In addition, high oxygen chemical and biochemical demand was also observed (Elias and Nakahodo, 1995).

Glycerol, lactic acid, ethanol, acetic acid, fructose, glucose, sucrose, galactose, acetate, oxalate, citrate and others are the organic components found in the highest ratios in sugar cane vinasse (Decloux and Bories, 2002; Parnaudeau, 2008; Doelsch et al., 2009). Vinasse may also contain phenolic compounds, cellulose and hemicellulose (Benke et al., 1998).

In sugar cane fertigation management systems, around 500 m3 ha-1 vinasse is applied per crop cycle (annual). Application is carried out via self-propelled irrigation systems equipped with a large sprinkler, which has a flow rate of m3 h-1 (Silva, 2006).

Tasso et al. (2007), while studying different residue types, sewage sludge + KCl and vinasse + urea doses regarding ratoon cane total recoverable sugar (TRS) changes, found higher TRS amounts in the treatments that received two residues that were not associated, compared to treatments that received the two residues in association.

From an environmental point of view, residue application in the soil, in a total area, causes its dilution, suggesting this application form. On the other hand, when considering residue use in agriculture, nutrient use and the beneficial effects that such products could eventually promote in the soil are of primary interest. Thus, through these principles, it can be stated that the application has advantages regarding residue agricultural efficiency as fertilizer (Có Júnior et al., 2008).

However, although studies show vinasse benefits in sugar cane and other crops (Barbosa et al., 2013; Silva et al., 2014), vinasse distribution uniformity in the area is necessary to avoid soil saturation, especially of K, as well as to provide nutrients in the product in appropriate quantities and under the law (CETESB, 2005).

Thus, this study aimed to hydraulically characterize four dripper models in relation to vinasse intermittent application, in order to check flow disorders.

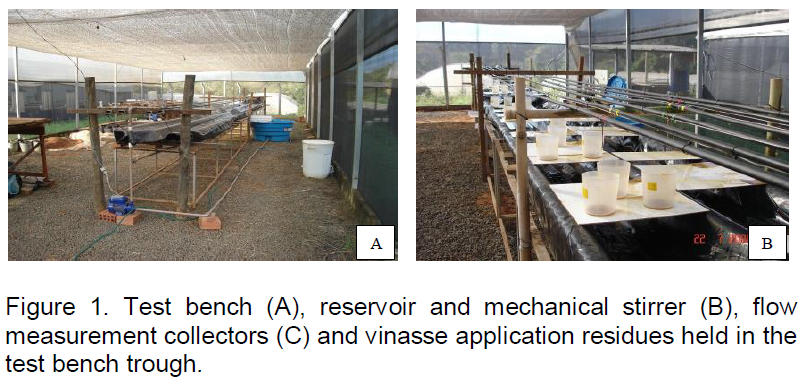

The study was conducted in a hydraulic test bench installed in the greenhouse from the Biosystem Engineering Department of ESALQ/University of São Paulo, located in Piracicaba, SP. Test benches had dimensions of 13 m x 1.5 m (Figure 1A).

The experimental design was completely randomized, with 10 repetitions. On a sideline, 10 drippers were randomly selected for repetition composition. Four dripline models (Hydrolite HY 0.65, Hydrolite HY 1.0, Drip Net PC DN 0.6 and Drip Net PC DN 1.6) and 13 consecutive weekly assessment periods were used as treatments. At the same time, drip line orifice position influence (upward and downward) was assessed in two (Hydrolite HY 0.65 and Drip Net PC DN 0.6) of the four drip line models in the respective periods (2x2x13 factorial = two models, two orifice positions and 13 periods/weeks). The flow of all drippers was collected in a graduated container (Figure 1B). Vinasse application was performed daily for 4 h, with the dripline product rest for 20 h and flow reading at every 168 test h (weekly).

Bench pressurization was conducted by a KSB, Hydrobloc P1000 model pump. The system was connected to a PVC tank with 500 L capacity equipped with a mechanical agitator, in order to homogenize vinasse. Therefore, organic matter decantation from the bottom of the reservoir was avoided. Bench operation regarding the start and stop time was conducted with the aid of a digital controller, which strictly obeyed application schedules.

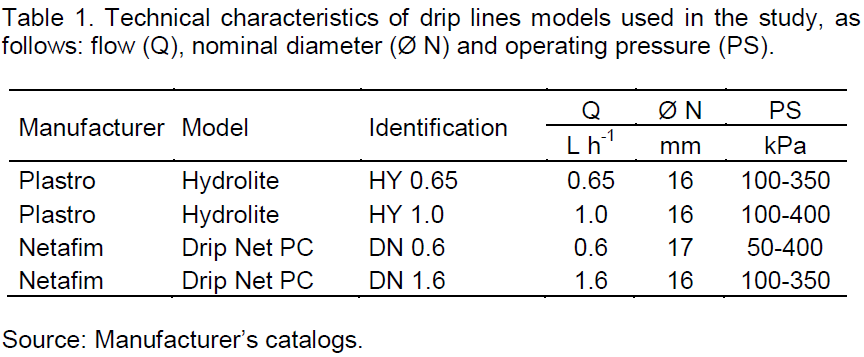

A pressure plug was installed before the input that connects driplines, allowing for pressure adjustment and, if necessary, adjustment to the pre-established pressure of 150 kPa. In order to measure working pressure, a digital manometer with 0-700 kPa reading range was used. The list of drip lines that were used in the study, and their technical features, is found in Table 1.

Emitter spacing in the drip line, as well as flow rates and pipe diameters, were adopted according to technical recommendation. However, dripper separation for bench testing was not conducted, avoiding differences related to amendments and emitter proximity influence by providing similar conditions to the field. The vinasse used in the study was obtained from Costa Pinto plant, COSAN Group, located in Piracicaba, SP. Vinasse was applied in the 2:1 concentration. Previously, vinasse chemical analysis was conducted according to the methodology proposed by Malavolta et al. (1989), resulting in the following values: pH=4.60; Electric conductivity (EC)=8.27 dS m-1; K=3.195 mg L-1; Ca=523 mg L-1; Na=59 mg L-1; NO3-=426 mg L-1 and S=890.37 mg L-1.

The vinasse was obtained at the plant fortnightly and applied to the test bench using a trough system that captured the product after it passed the driplines. Afterwards, the product was routed back to the collection tank, thus, keeping a closed circuit. A 100 mesh disc filter was used and a ¾’ shut-off valve was coupled in the main line to control the application. Driplines were joined at the beginning and at the end by ¾’ shut-off valves and PVC connections supported by devices that allowed for maintaining 0.15 m spacing between horizontal lines and 0.50 m spacing above the trough system.

Firstly, 36 h irrigation was conducted with the four dripper models under study, where two dripper models (Hydrolite HY 0.65 and Drip Net PC DN 0.6) had drip lines with orifices downwards and upwards. The other two models (Hydrolite HY 1.0 and Drip Net PC DN 1.6) were installed on the test bench with orifices faced only upwards, thus, consisting of an irrigation system with six driplines.

Application was conducted daily at an interval of 4 h with the product resting on the line for 20 h, and pressure was measured during each application. A certified precision scale (OHAUS) with an accuracy of 0.01 g was used to weigh each container with the applied solution. Flow reading procedure for each dripper consisted of system pressurization (150 kPa), plastic container positioning (1 L) under their respective drippers with five-second delays, sequential recipient withdrawal after 5 min with 5 s delays, weighing (gravimetric method) and data tabulation, with flow values expressed in L h-1 (Figure 1).

After the data was tabulated, mean flow, flow variation coefficient and water distribution uniformity were calculated using equations 1 to 3.

Variance analysis showed significant effects (p <0.01) for dripper model, assessment time and interaction between

the two factors (Table 2). The variation coefficient was 3.60%, which is considered low (Pimentel-Gomes, 1990), showing good data accuracy.

From a practical point of view, emitter mean flow can be considered a good parameter to assess changes regarding emitter proper functioning, which may be caused both by clogging problems (Cararo et al., 2006; Ribeiro and Paterniani, 2008) or by damage to the emitter internal structure caused by chemical action (Souza et al., 2006; Coelho and Teixeira, 2009), hindering flow uniformity (Frizzone et al., 1998).

It was observed in Table 3 that the different models under study, regardless of dripper orifice positioning, showed no significant flow reduction due to vinasse application. This was probably due to vinasse acid constitution and its fluidity (particulate matter), which prevented its sedimentation in the dripper pre-filter chamber, maze and orifice, as was also observed by Lelis Neto (2012).

Therefore, observing other aspects, such as the chemical characteristic of the applied product and the solution volume to which the emitter was exposed become important, as they may contribute to clogging (Lelis Neto, 2012) and application non-uniformity (Frizzone et at., 1998) along with the water passage orifice diameter.

The Hydrolite model, with the exceptions of the second (168 h) and seventh (1008 h) assessment weeks, showed higher flows than the Drip Net model until the ninth assessment week. In the last three weeks, the opposite behavior occurred, that is, the Drip Net model showed higher flow than Hydrolite.

Regarding orifice position, downwards orifice flow only occurred in the seventh and the ninth weeks. Meanwhile, the upwards orifice had higher flow in the tenth assessment week. However, in periods with significant differences, except for the first week, in which the Hydrolite model showed a 14.8% higher flow than Drip Net, flows did not differ much, with total flow values lower than 8.5%.

It was observed in Table 4 that, in the HY model, the applied vinasse volume was the highest among all dripper models tested models. However, this value was lower than the volume generally used in the field, which is about 500 m3 ha-1 (Lelis Neto, 2012), contributing to clogging non-occurrence for this drip line during the study period.

There are different emitter classifications regarding flow uniformity, of which the Abnt (1986) standard may be cited, which classifies flow uniformity with CVF up to 10% as good. It was observed in Figure 2 that, for the different dripline models under study, regardless of dripper orifice position (downwards or upwards), there were no CV values (%) higher than 10%, allowing for classifying them as well, according to Abnt (1986), and as adequate, according to Asae (1999).

Except for the DN model (0.6 L h-1) with drippers positioned downwards, all others showed water distribution uniformity values higher than 90% throughout the experiment (Figure 3).

All drippers evaluated did not undergo significant flow reduction, and were classified as little sensitive to clogging by vinasse application. Flow values low variation

indicated that, regardless of dripper arrangement (downwards or upwards), they were classified as good (Abnt, 1986) and appropriate (Asae, 1999).

The authors have not declared any conflict of interests.

The authors sincere thanks go to the Ministry of Science and Technology (MCT), to the National Council for Scientific and Technological Development (CNPq), to the Higher Education Personnel Improvement Coordination (CAPES), to the São Paulo State Research Support Foundation (FAPESP), to the Goiás State Research Support Foundation (FAPEG) and to FINEP for the financial support to this research.

REFERENCES

|

ABNT (1986). Associação Brasileira de Normas Técnicas. Emissores para sistemas de irrigação localizada – avaliação das características operacionais. PNBR 12: 02 – 08 – 02. São Paulo. 7 p.

|

|

|

|

ANDA (2012). Associação Nacional para Difusão de Adubos. Disponível em:

View.

|

|

|

|

|

ASAE Standards (1999) Standards engineering practices data: EP405.1. Design and installation of microirrigation systems. St. Joseph, Mich: Am. Society Agric. Eng. Dec. pp. 879-883.

|

|

|

|

|

Barbosa EAA, Arruda FB, Pires RCM, Silva TJA da, Sakai E (2013). Cana-de-açúcar fertirrigada com vinhaça via irrigação por gotejamento subsuperficial em três ciclos de cana-soca. Rev. Bras. Engenharia Agríc. Ambient. 17(6):588-594.

|

|

|

|

|

Benke MB, Mermut AR, Chatson B (1998). Carbon-13 CP/MAS NMR and DR-FTIR spectroscopic studies of sugarcane distillery waste. Can. J. Soil Sci. 78(1):227-236

Crossref

|

|

|

|

|

Brito FL, Rolim MM, Pedrosa EMR (2009). Efeito da aplicação de vinhaça nas características de solos da zona da mata de Pernambuco. Rev. Bras. Ciênc. Agrárias 4(4):456-462.

|

|

|

|

|

Cararo DC, Botrel TA, Hills DJ, Leverenz HL (2006). Analysis of clogging in drip emitters during wastewater irrigation. Appl. Eng. Agric. St. Joseph 22(2):251-257.

Crossref

|

|

|

|

|

CETESB (1999). Companhia de Tecnologia de Saneamento Ambiental – CETESB. Norma técnica: P4.230 - Aplicação de lodos de sistema de tratamento biológico em áreas agrícolas – critérios para projeto e operação. São Paulo 32p.

|

|

|

|

|

CETESB (2005). Companhia de Tecnologia de Saneamento Ambiental – CETESB. Norma técnica: P4.231 - Vinhaça – critérios e procedimentos para aplicação no solo agrícola. São Paulo 17p.

|

|

|

|

|

Có Júnior C, Marques MO, Tasso Júnior LC (2008). Efeito residual de quatro aplicações anuais de lodo de esgoto e vinhaça na qualidade tecnológica da cana-de-açúcar. Rev. Engenharia Agríc. Jaboticabal 28(1):196-203.

|

|

|

|

|

Coelho RD, Teixeira MB (2009). Chemical damages of chlorine and acid applications on compensating drippers. ASABE Annual International Meeting, Reno, Nevada. P 95542.

|

|

|

|

|

Doelsch E, Masion A, Cazevieille P, Condom N (2009). Spectroscopic characterization of organic matter of a soil and vinasse mixture during aerobic or anaerobic incubation. Waste Management, Amsterdam 29(6):1929-1935.

Crossref

|

|

|

|

|

Decloux M, Bories A (2002). Stillage treatment in the French alcohol fermentation industry. International Sugar Journal, London 104 (1247):509–517.

|

|

|

|

|

Elias Neto A, Nakahodo T (1995). Caracterização físico-química da vinhaça - projeto nº 9500278. Relatório Técnico. Piracicaba: Seção de Tecnologia de Tratamento de Águas do Centro de Tecnologia Copersucar, 1995. 26 p.

|

|

|

|

|

Parnaudeau V, Condom N, Oliver R, Cazevieille P, Recous S (2008). Vinasse organic matter quality and mineralization potential, as influenced by raw material, fermentation and concentration processes. Biorecource Technology, Essex 99(6):1553-1562.

Crossref

|

|

|

|

|

Frizzone JA, Vieira AT, Paz VP da S, Brotel TA (1998). Caracterização hidráulica de um tubo gotejador. Revista Brasileira de Engenharia Agrícola e Ambiental. Campina Grande 2(3):278-283.

|

|

|

|

|

Lelis Neto JA (2012). Aplicação de vinhaça via gotejamento subsuperficial e seus efeitos nos perfis de distribuição iônico e atributos físicos e químicos de um Nitossolo. 138p. Tese (Doutorado) – Escola Superior de Agricultura "Luiz de Queiroz", Piracicaba.

|

|

|

|

|

Malavolta E, Vitti GC, Oliveira SA (1989). Avaliação do estado nutricional das plantas: princípios e aplicações. Piracicaba: Associação Bras. para a Pesqui. da Potassa e do Fosfato. pp. 135-139.

|

|

|

|

|

Marques MO (2006). Aspectos técnicos e legais da produção, transporte e aplicação de vinhaça. In: Segato SV, Pinto AS, Jendiroba E, Nóbrega JCM (Org.). Atualização em produção de cana-de-açúcar. Piracicaba: Editoral, p. 369-375.

|

|

|

|

|

Pimentel-Gomes F (1990). Curso de estatística experimental. 13.ed. Piracicaba: Nobel 468p.

|

|

|

|

|

Ribeiro TAP, Paterniani JES (2008). Microaspersores entupidos devido a problemas de ferro na água. Rev. Ciênc. Rural Santa Maria 38(5):1456-1459.

Crossref

|

|

|

|

|

SAS (1999). Statistical Analyses System. The SAS system for Windows Version 8. 5 ed. Cary 88p.

|

|

|

|

|

Silva AJN da, Cabeda MSV, Carvalho FG de, Lima JFWF (2006). Alterações físicas e químicas de um Argissolo amarelo sob diferentes sistemas de uso e manejo. Rev. Bras. Engenharia Agríc. Ambient. Campina Grande 10(1):76-83.

|

|

|

|

|

Silva APM da, Bono JAM, Pereira FAR de (2014). Aplicação de vinhaça na cultura da cana-de-açúcar: Efeito no solo e na produtividade de colmos. Rev. Bras. Engenharia Agríc. Ambient 18(1):38-43.

|

|

|

|

|

Sousa DMG, Lobato E (2004). Calagem e adubação para culturas anuais e semiperenes. In: Sousa DMG, Lobato E (Eds). Cerrado – Correção do Solo e Adubação, 2.ed. Planaltina-DF, EMBRAPA – CPAC. pp. 283-316.

|

|

|

|

|

Souza JAA de, Cordeiro EA de, COSTA EL da (2006). Aplicação de hipoclorito de sódio para recuperação de gotejadores entupidos em irrigação com água ferruginosa. Rev. Bras. Engenharia Agríc. Ambient. Campina Grande 10(1):5-9.

|

|

|

|

|

Tasso Júnior LC, Marques MO, Franco A, Nogueira G de A, Nobile FO de Camilotti F, Silva AR da (2007). Produtividade e qualidade de cana-de-açúcar cultivada em solo tratado com lodo de esgoto, vinhaça e adubos minerais. Rev. Engenharia Agríc. Jaboticabal 27(1):276-283.

|

|

|

|

|

UNICA (2012). UNIÃO DA INDÚSTRIA DE CANA-DE-AÇÚCAR. Disponível em:

View.

|

|