ABSTRACT

Golden berry (Physalis peruviana L.) has scientifically proven medicinal properties. This research was aimed to investigate the effect of alkaline ethyl oleate and sucrose solution pretreatments as well as drying temperature on the drying kinetics of golden berry. Based on this, golden berries were dipped in alkaline ethyl oleate solution (2% ethyl oleate + 4% potassium carbonate) at 25°C or in osmotic solution (40% sucrose) at 60°C. After those pretreatments, air drying characteristics of golden berry (P. peruviana L.) were investigated at 70, 75, 80 and 85°C with 1.5 m/s air flow rate. Also, golden berries were dried without pretreatment and taken as a control. The experimental data was fitted to Page model. Two statistical tools were used to quantify the goodness of fitting: the determination of coefficient and the reduced chi-square. Obtained effective diffusivity for pretreatment of alkaline ethyl oleate and sucrose solution and untreated samples varied between 1.94 to 3.19·10-9 m2/s, 1.21 to 2.93·10-9 and 1.66 to 2.67·10-9 m2/s respectively.

Key words: Physalis perviana L., alkaline ethyl oleato, osmotic dehydration, effective diffusivity, Page model

Physalis peruviana, is known as “Güvey Feneri” in Turkey, “Uvilla” in Ecuador, “Topotopo” in Venezuela and “Golden Berry” in English speaking countries. Generally, the fruit of P. peruviana is consumed fresh which provides an acid-sweet balance of fruit and vegetable salads. Also, the whole fruit can be dried and it can be consumed as a very nice raisin (Puente et al., 2011). Golden berry (P. peruviana L.) has scientifically proven medicinal properties such as anticancer, antimicrobial and antipyretic effects (Franco et al., 2007; Puente et al., 2011). The major objective in drying agricultural products is the reduction of the moisture content to a level which allows safe storage over an extended period (Doymaz, 2004). Golden berry is a highly perishable fruit that is a strong limiting factor on its commercialization. So that studies on drying of golden berry is thought as necessary and fulfill the requirement of industry.

Several fruits and vegetables, such as grapes, plums, apricots, peppers, tomatoes and physalis are covered naturally with a thin layer of wax. This outer layer offers benefits such as protection to the fruit or vegetable from environmental and external factors. The wax layer also affects the flow of moisture from inside of the fruit to its surface which is a crucial process in drying (Sagar and Suresh, 2010). Due to that, chemical dipping pre-treatments such as methyl ethyl ester emulsion or alkaline pretreatment have been used prior to the drying process. Prior to drying process, chemical dipping such as methyl and ethyl ester emulsions or alkaline pretreatment in aqueous solutions of sodium hydroxide, sodium chloride, potassium carbonate and calcium chloride have been used to overcome the wax barrier on fruits or vegetables.

Dipping waxy fruits for several seconds in solution of ethyl oleate or other suitable compound greatly reduces drying time. The effects of dipping solutions on various fruits and vegetables during drying are reported in literature (Riva and Peri, 1986; Doymaz and Pala, 2002). Before drying, fruits or vegetables are pretreated in various solutions such as calcium chloride (Al-Harahsheh et al., 2009), sodium chloride (McMinn and Magee,1999; Sacilik et al., 2006), and sodium chloride-sucrose (Azoubel et al., 2004) and then can be dried in different shapes such as halves, slices and quarters (Souza et al., 2007; Cernisev, 2010). However, no reports have been found detailing the effects of alkaline ethyl oleate solution or sucrose solution pretreatment on drying of golden berry in the literature. This study was aimed to investigate the effect of alkaline ethyl oleate and sucrose solutions on golden berry drying period, to calculate effective moisture diffusivity and to fit the experimental data with Page model.

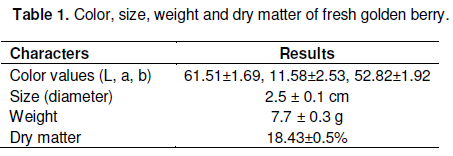

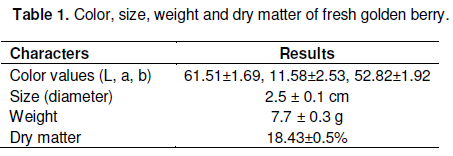

Mature golden berries were harvested in observation garden of Ataturk Central Horticultural Research Institute (Yalova, Turkey). Color, size, weight and dry matter of fresh golden berry were given in Table 1.

Dipping pretreatment

Golden berries were washed in fresh running water and divided in three sample groups. One sample group was dipped in alkaline ethyl oleate (AEO) solution which contained 2% ethyl oleate and 4% potassium carbonate at 25°C for 1 min. Other one sample group was dipped in 40% sucrose solution (SC) at 60°C. The AEO or SC volume to golden berry weight ratio were kept ratio 4:1. No pretreatment (NP) was applied to one sample group and dried as a control group.

Drying

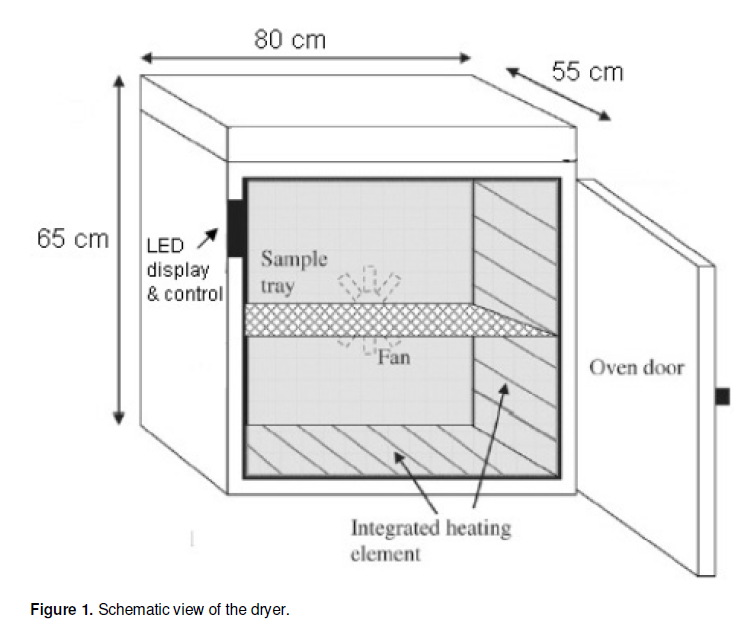

Drying experiments were performed in a laboratory scale hot-air dryer which was illustrated in Figure 1. This dryer was installed in the Food Technology Department of Ataturk Central Horticultural Research Institute; desired experiment conditions inside the dryer were obtained for at least 1 h prior to each run.

Pretreated and non pretreated sample groups were spread on a perforated tray. Drying runs of all sample groups were conducted at four temperatures (70, 75, 80 and 85°C) with fixed 1.5 m/s air flow both ascending and descending. Moisture loss was recorded automatically during drying by means of a digital balance (Nuve, model FN500S) with an accuracy of ±0.01 g. The drying was carried out to final moisture content reduced to 3%. Drying process was applied in triplicate.

Mathematical modeling of drying curves

The moisture ratio (MR) of samples was calculated using the following equation:

where Mt is the water content at any time (kg water/kg dry solid), M0 is the initial water content (kg water/kg dry solid), and Me is equilibrium water content of sample (kg water/kg dry solid). The values of Me are relatively small compared to Mt or M0, thus the error involved in the simplification is negligible (Diamante and Munro, 1993). In this study, Me was accepted as zero.

Obtained drying curves of the golden berries were fitted with Page model. This model is widely used to describe the drying characteristics of various vegetables and fruits such as kiwi fruit, pear, mango, potato, eggplant and cherry tomato (Diamante and Munro, 1993; Ertekin and Yaldiz, 2004; Simal et al., 2005; Goyal et al., 2006). The model is written as follows:

where k and n are drying constant.

Calculation of effective diffusivity and activation energy

The effective diffusivity (Deff) is also typically calculated according to Sobukola et al. (2007) by using the slope of Equation (3), namely, when natural ln (MR) versus time was plotted, a straight line with a slope k0 was obtained:

t: drying time (h)

L = average diameter of golden berry (m).

Analysis of drying process

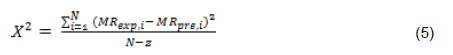

Page moisture ratio model was fitted to the drying data and the model parameters determined using non-linear regression analysis. The terms used to evaluate goodness of fit of the tested models to the experimental data were the coefficient of determination (R2) and the reduced chi-square (X2) between the experimental and predicted moisture ratio values. The reduced chi-square (X2) could be calculated as following:

where MRexp,i and MRpre,i were experimental and predicted moisture ratios, respectively, N was number of observations, and z was number of drying constants (Sarsavadia et al., 1999).

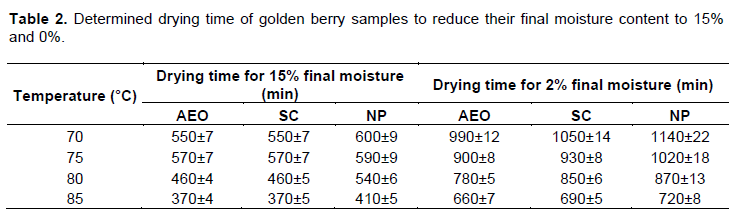

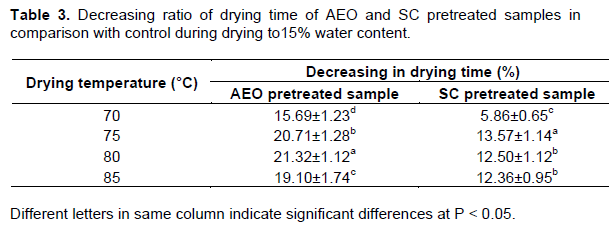

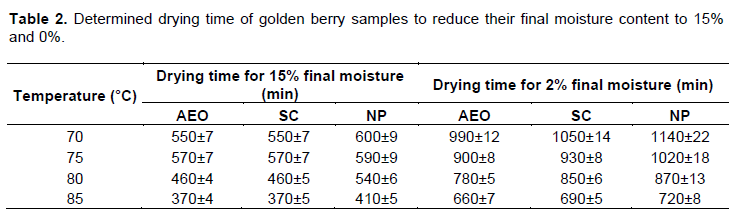

Effect of the pretreatments and drying temperatures on drying time of golden berry were given in Table 2. Moisture content of golden berry is reduced to 15% and after that 3% for evaluating and fitting of drying model. Increase in drying temperature was determined to be caused dramatic reduction on drying time. Similar results were given in literature for golden berry (Valdenegro et al., 2013), tomato (Cernisev, 2010) and grape (Doymaz, 2006). Drying times to reduce the final moisture content to 15% was investigated in the order NP>SC>AEO at all temperature levels in this study. Thus, it can be seen that the pretreatment using dipping immersion in AEO was more effective than sucrose solution in to reduce the drying time.

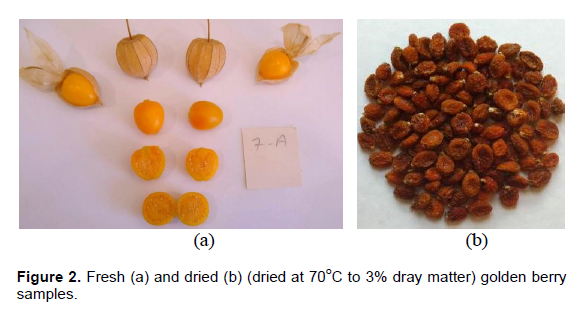

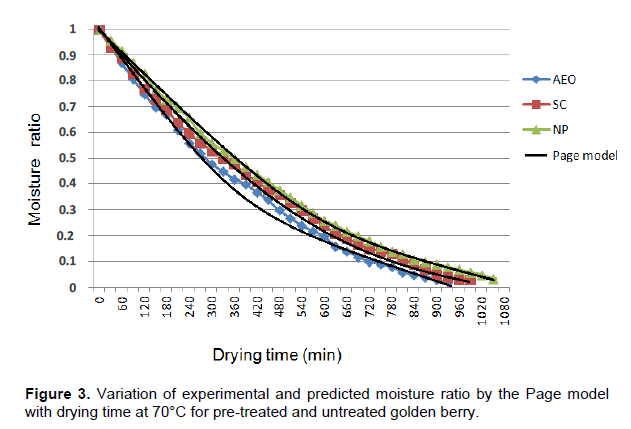

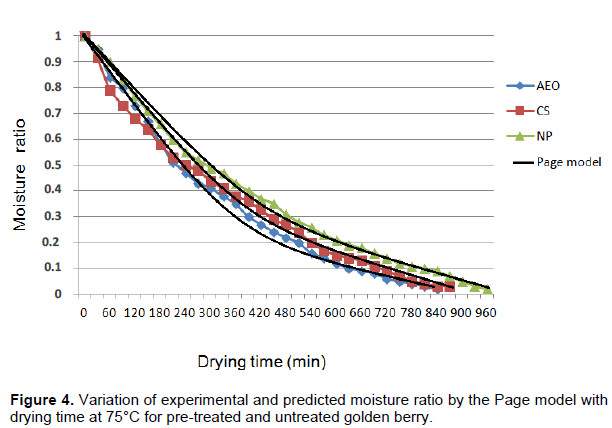

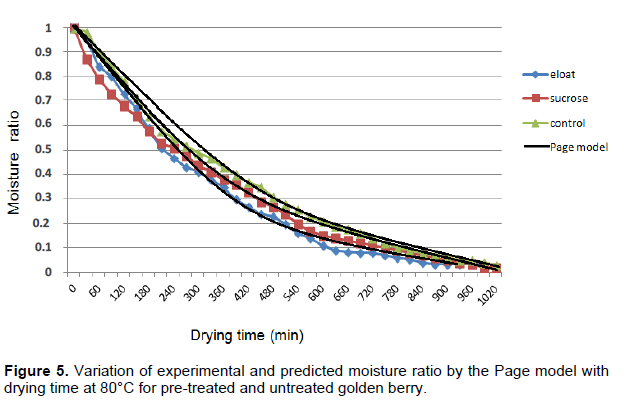

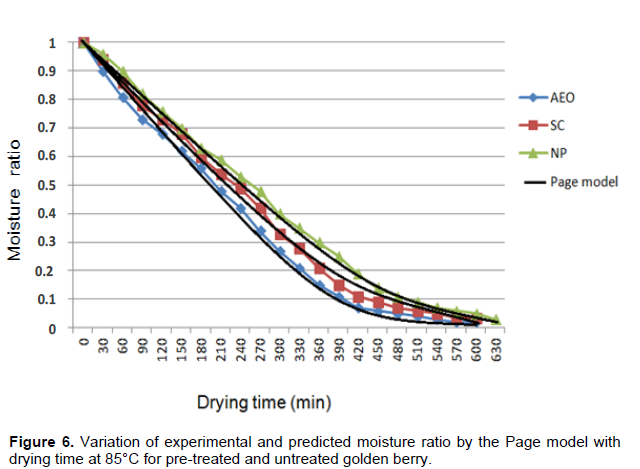

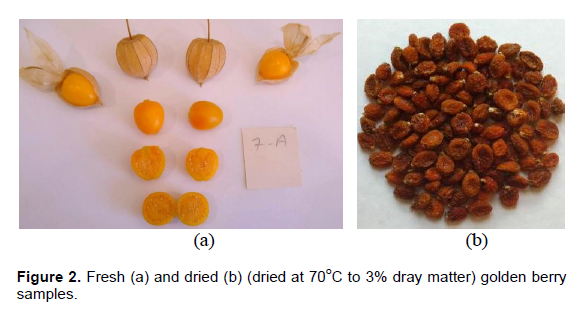

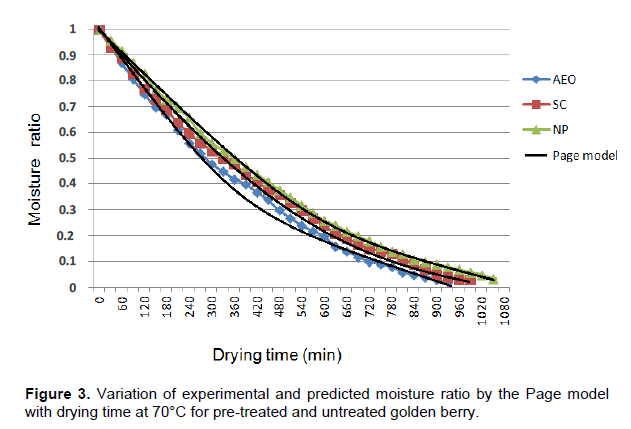

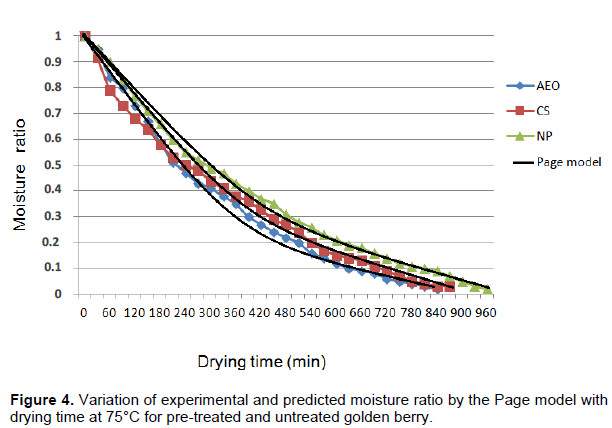

Fresh and dried golden berry samples were given in Figure 2. The effects of the pretreatments on the moisture ratio of the golden berry over drying time were shown in Figures 3 to 6. From these figures, pretreatment solution was detected as an important factor for the golden berry drying because it affected the drying time.

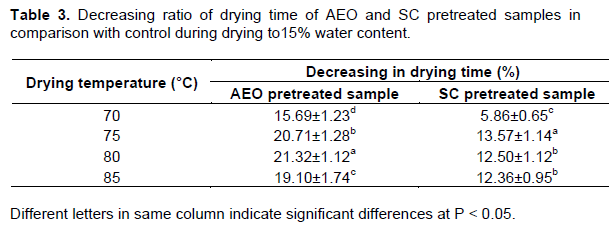

Hence, AEO and SC could decrease the drying time more than untreated samples to reduce the moisture content to 15% for all temperatures. Decreasing ratio of drying time of AEO and SC pretreated samples in comparison with control was given in Table 3. It can be seen that the increase in temperature used promoted a considerably reduction in drying time (Table 3).

Similar results were found for alkaline ethyl oleate in the air drying of grapes (Doymaz, 2006), red pepper (Doymaz and Pala, 2002), apricot (Doymaz, 2004). In this research osmotic pretreatment reduced the drying time less than results of some research such as golden berry (Castro et al., 2008), acerola fruit (Agnelli et al., 2005), apple (Sereno et al., 2001), melon (Telas et al., 2006) and tomato (Souza et al., 2007). Expectedly, during the initial stages of drying there was a rapid moisture removal from the product which later decreased with increase in drying time. Remaining quantity of water is bounded more strongly while its quantity decreased so that drying rates decreased when moisture content decreased. Under the monolayer moisture level, water is firmly bound to the solutes of the golden berry so that in this study water was hardly removed when remaining water were decreased. From Figures 3 to 6, it can be seen that the moisture ratio decreases continually with drying time. As expected, the drying air temperatures had statistically significant effect on the drying moisture content of golden berry.

The temperature influence was highest at 85°C air temperature, as expected. There was no constant rate drying period in these curves, all drying processes occurred in falling rate-drying period. During the falling drying rate period, the drying process of golden berry was mainly controlled by diffusion mechanisms. Similar results have been reported in the literature for various fruits and vegetables (Diamante and Munro, 1993; Azoubel et al., 2004; Lahsasni et al., 2004; Simal et al., 2005; Akanbi et al., 2006; Goyal et al., 2006).

Modeling of drying kinetics

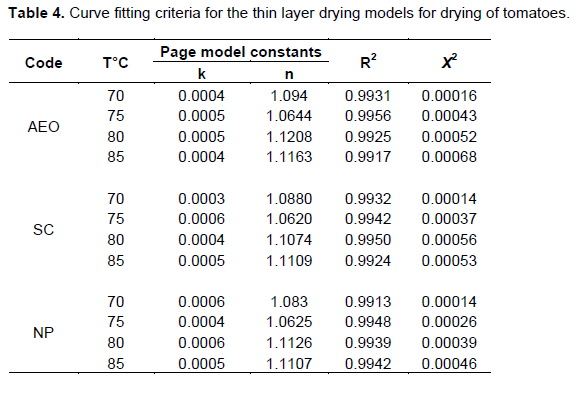

The obtained drying data were fitted by Page model. The results of statistical analysis for Page model were shown in Table 4. Acceptable R2 of greater than 0.98 were obtained for model fitted to all drying tests. The R2 ranged from 0.9917 to 0.9956 in Page model. The X2 value varied from 0.00014 to 0.00068.

Similar results about Page model have been reported by Sacilik et al. (2006). Figures 3 to 6 showed the variations of experimental and predicted moisture ratios by the Page model withdrying time. According to these figures, Page model showed good agreement with the experimental data obtained from the drying experiments. Similar results were reported in the literature for some vegetables and fruits (Doymaz and Pala, 2002; Azoubel et al., 2004; Lahsasni et al., 2004; Simal et al., 2005; Al-Harahsheh et al., 2009).

Calculation of effective diffusivity

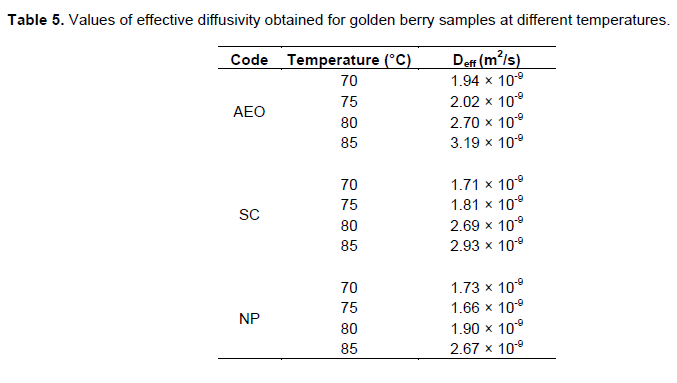

Modeling of drying kinetics, as well as acquiring data on desorption isotherm or diffusion coefficient, is needed by the industry to manage efficiently dehydration techniques and avoid energy misuse (Vegaâ€Gálvez et al., 2014). The calculated values of Deff for different temperatures were presented in Table 5. The effective diffusivity values of dried samples at 70 to 85°C were varied in the range of 1.94 to 3.19×10-9 m2/s for AEO pretreated samples, 1.71 to 2.93×10-9 m2/s for SC pretreated samples and 1.66 to 2.67×10-9 m2/s for untreated samples (control group).

Determined effective moisture diffusivity were similar with found by Vega-Gálvez et al. (2014) and higher than that found by Vásquez-Parra et al. (2013). The obtained values were in the suitable range for other similar sized products reported in the literature such as grape (Karathanos and Belessiotis, 1997). It can be seen that the values of Deff increased greatly with increasing temperature. Drying at 85°C gave the highest Deff values. Deff values for golden berries were different to those estimated by different authors for other vegetables: 3.72 to 12.27×10-9 m2/s for tomatoes dried from 45 to 75°C (Akanbi et al., 2006); 2.02×10-9 m2/s for hot air drying of paprika at 60°C (Ramesh et al., 2001); 0.87 to 1.0×10-9 m2/s for cherry tomato dried from 40 to 60°C (Varadharaju et al., 2001); 1.79 to 4.45×10-9 m2/s for apple slices at 60°C (Velic et al., 2004); 2 to 4.2×10-10 m2/s for garlic slices dried from 50 to 90°C (Madamba et al., 1996). Some of these values were lower than and some of these similar with estimated Deff values of golden berry in this research. In these dyring kinetic studies of foods Deff values were determined at different levels because of different drying parameters such as temperature and relative humidity, dried material and used drying equipments.

Alkaline ethyl oleate and sucrose solutions were used as pretreatment for golden berry drying process affected strongly the characteristics of the dried product. Pretreated golden berry with alkaline ethyl oleate solution dried faster than untreated samples. Drying curves of golden berries showed a falling rate drying period; did not showing a constant rate drying period. Page exponential model was considered as appropriate for explaining the drying features of golden berries.

Golden berry has a small size like chery tomato so that it has higher diffusion coefficient than other fruits and vegetables which have bigger size. In addition, high core content and different texture structure of golden berry may cause increase on diffusion coefficient when compared with other fruits and vegetables during same drying conditions such as temperature and relative humidity. AEO and SC pretreatment could reduce the drying time of golden berry so that energy could be saved.

Authors disclose that there is no financial/relevant conflict of interests.

This research was carried out in “Nutrient Content Determination and Conformity Investigation for Drying of Some Golden berry (Physalis peruviana L.) Types” project which was supported by Republic of Turkey Ministry of Food, Agriculture and Livestock.

REFERENCES

|

Agnelli ME, Marani CM, Mascheroni RH (2005). Modelling of heat and mass transfer during (osmo) dehydrofreezing of fruits. J. Food Eng. 69(4):415-424.

Crossref

|

|

|

|

Akanbi CT, Adeyemi RS, Ojo A (2006). Drying characteristics and sorption isotherm of tomato slices. J. Food Eng. 73:141-146.

Crossref

|

|

|

|

|

Al-Harahsheh M, Al-Muhtaseb AH, Magee TRA (2009). Microwave drying kinetics of tomato pomace: Effect of osmotic dehydration. Chem. Eng. Process. 48:524-531.

Crossref

|

|

|

|

|

Azoubel MP, Elizabeth F, Murr X (2004). Mass transfer kinetics of osmotic dehydration of cherry tomato. J. Food Eng. 61:291-295.

Crossref

|

|

|

|

|

Castro AM, Rodriguez L, Vargas EM (2008). Dry gooseberry (Physalis peruviana L) with pretreatment of osmotic dehydration. Revista de la Facultad de Química Farmacéutica 15:226-231.

|

|

|

|

|

Cernisev S (2010). Effects of conventional and multistage drying processing on non-enzymatic browning in tomato. J. Food Eng. 96:114-118.

Crossref

|

|

|

|

|

Diamante LM, Munro PA (1993). Mathematical modeling of the thin-layer solar drying of sweet potato slices. Sol. Energy 51:271-276.

Crossref

|

|

|

|

|

Doymaz I (2004). Drying kinetics of white mulberry. J. Food Eng. 61:341-346.

Crossref

|

|

|

|

|

Doymaz I (2006). Drying kinetics of black grapes treated with different solutions. J. Food Eng. 76:212-217.

Crossref

|

|

|

|

|

Doymaz I, Pala M (2002). Hot air drying characteristics of red pepper. J. Food Eng. 55:331-335.

Crossref

|

|

|

|

|

Ertekin C, Yaldiz O (2004). Drying of eggplant and selection of a suitable thin layer drying model. J. Food Eng. 63:349-359.

Crossref

|

|

|

|

|

Franco L, Matiz G, Calle J, Pinzon R, Ospina L (2007). Antiinflammatory activity of extracts and fractions obtained from Physalis peruviana L. Calyces. Biomedica 27:110-115.

Crossref

|

|

|

|

|

Goyal RK, Kingsly ARP, Manikantanl, MR, Ilyas SM (2006). Thin-layer drying kinetics of raw mango slices. Biosyst. Eng. 95:43-49.

Crossref

|

|

|

|

|

Karathanos VT, Belessiotis VG (1997). Sun and artificial air drying kinetics of some agricultural products. J. Food Eng. 31:35-46.

Crossref

|

|

|

|

|

Lahsasni S, Kouhila M, Mahrouz M, Mohamed L, Agorram B (2004). Characteristic drying curve and mathematical modeling of thin-layer solar drying of prickly pear cladode (Opuntia ficus indica). J. Food Process. Eng. 27:103-117.

Crossref

|

|

|

|

|

Madamba PS, Driscoll RH, Buckle KA (1996). The thin-layer drying characteristics of garlic slices. J. Food Process. Eng. 29:75-97.

Crossref

|

|

|

|

|

Mcminn WAM, Magee TRA (1999). Studies on effect of surfactant, blanching and osmotic pretreatments on the convective drying of potatoes. Drying Technol. 22:419-433.

Crossref

|

|

|

|

|

Puente LA, Pinto-Mu-oz CA, Castro ES, Cortés M (2011). Physalis peruviana Linnaeus, the multiple properties of a highly functional fruit: A review. Food Res. Int. 44:1733-1740.

Crossref

|

|

|

|

|

Ramesh MN, Wolf W, Tevini D, Jung G (2001). Influence of processing parameters on the drying of spice paprika. J. Food Eng. 49:63-72.

Crossref

|

|

|

|

|

Riva M, Peri C (1986). Kinetics of sun and air drying of different varieties of seedless grapes. J. Food Technol. 21:199-208.

Crossref

|

|

|

|

|

Sacilik K, Keskin R, Elicin AK (2006). Mathematical modelling of solar tunnel drying of thin layer organic tomato. J. Food Eng. 73:231-238.

Crossref

|

|

|

|

|

Sagar VR, Suresh KP (2010). Recent advances in drying and dehydration of fruits and vegetables: a review. J. Food Sci. Technol. 47:15-26.

Crossref

|

|

|

|

|

Sarsavadia PN, Sawhney RL, Pangavhane DR, Singh SP (1999). Drying behavior of brined onion slices. J. Food Eng. 40:219-226.

Crossref

|

|

|

|

|

Sereno AM, Moreira R, Martinez E (2001). Mass transfer coefficients during osmotic dehydration of apple in single and combined aqueous solutions of sugar and salt. J. Food Eng. 47(1):43-49.

Crossref

|

|

|

|

|

Simal S, Femenia A, Garau MC, Rossello C (2005). Use of exponential, Page's and diffusional models to simulate the drying kinetics of kiwi fruit. J. Food Eng. 66:323-328.

Crossref

|

|

|

|

|

Sobukola OP, Dairo OU, Sanni LO, Odunewu AV, Fafiolu BO (2007). Thin layer drying process of some leafy vegetables under open sun. Food sci. Technol. Int. 13:35-40.

Crossref

|

|

|

|

|

Souza JZ, Medeiros MFD, Magalhaes MMA., Rodrigues S, Fernandes FAN (2007). Optimization of osmotic dehydration of tomatoes in a ternary system followed by air-drying. J. Food Eng. 83:501-509.

Crossref

|

|

|

|

|

Teles UM, Fernandes FA, Rodrigues S, Lima, AS, Maia GA, Figueiredo RW (2006). Optimization of osmotic dehydration of melons followed by airâ€drying. Int. J. Food Sci. Tech. 41(6):674-680.

Crossref

|

|

|

|

|

Valdenegro M, Almonacid S, Henríquez C, Lutz M, Fuentes L, Simpson R (2013). The effects of drying processes on organoleptic characteristics and the health quality of food ingredients obtained from goldenberry fruits (Physalis peruviana). Sci. Rep. 2:1-7.

|

|

|

|

|

Varadharaju N, Karunanidhi C, Kailappan R (2001). Coffee cherry drying: A two-layer model. Drying Technol. 19:709-715.

Crossref

|

|

|

|

|

Vásquez-Parra JE, Ochoa-Martínez CI, Bustos-Parra M (2013). Effect of chemical and physical pretreatments on the convective drying of cape gooseberry fruits (Physalis peruviana). J. Food Eng. 119: 648-654.

Crossref

|

|

|

|

|

Vegaâ€Gálvez A, Puenteâ€Díaz L, Lemusâ€Mondaca R, Miranda M, Torres MJ (2014). Mathematical modeling of thinâ€layer drying kinetics of cape gooseberry (Physalis peruviana L.). J. Food Process. Preserv. 38:728-736.

Crossref

|

|

|

|

|

Velic D, Planinic M, Tomas S, Bilic M (2004). Influence of airflow velocity on kinetics of convection apple drying. J. Food Eng. 64:97-102.

Crossref

|

|