Full Length Research Paper

ABSTRACT

The present paper reports an experimental work of the influence of initial substrate concentration on the adaptability of bacterial cells and the biodegradation kinetics of the substrate in a submerged aerobic fixed-film reactor, by studying some physicochemical parameters. The bioreactor used in this study is gotten from the biological aerated filter (BAF), but the used filter media is made of plastic of a large size than that used usually in BAF and with a high specific surface. For this purpose, various synthetic wastewaters were prepared based on a non-toxic substrate, in this case, glycerol, and some salts of nitrogen, phosphorus and some oligo-elements with different initial chemical oxygen demand (COD) of: 330 MgO2/L (S1), 480 MgO2/L (S2), 860 MgO2/L (S3) and 1120 MgO2/L (S4). Experiments have been carried out at laboratory scale in a cylindrical reactor, made of PVC (height of 1 m and diameter of 0.125 m). The pilot was filled by a Biocell® (PE05) packing fixed between two grids. The analysis of various physicochemical parameters, during biodegradation (COD, dissolved oxygen, pH, turbidity), showed that the performances of the submerged aerobic fixed-film reactor were influenced by the initial substrate concentration. In low concentrations, the adaptability of bacterial cells was easy and relatively quick. Biodegradation kinetics constants reached 0.407, 0.346, 0.341 and 0.232 d-1 respectively for synthetic wastewaters S1, S2, S3 and S4. It has been found that the physicochemical parameters could be used for monitoring the adaptability and the biodegradation process of the substrate. Turbidity was revealed as a good indicator for biofilm growth, mainly because of its decrease during the adaptation phase and its increase during the biodegradation phase. In the same time, the pH increased especially during biodegradation phase. In parallel, DO decreased gradually.

Key words: Submerged aerobic fixed-film reactor, adaptability, biodegradation kinetics, packing, synthetic wastewater, chemical oxygen demand (COD).

INTRODUCTION

Submerged aerobic fixed-film reactors are mainly used for carbonaceous, and ammonia removal in the aerobic treatment of urban wastewaters. They are also used in secondary or in tertiary treatment. Today, these bioreactors have several applications in industry (Mendoza-Espinoza et al., 1999; Chaudhary et al., 2003). They combine compactness and high removal efficiencies in a large range of hydraulic and organic load. In secondary treatment, aerobic biological degradation of organic matters in submerged aerobic fixed-film reactor is made in the presence of bacteria according to the reactions in Figure 1.

This degradation involves three reactions in the same time: the first one (Reaction 1) corresponds to an oxidation of organic matter with H2O and CO2 as byproducts, it releases also energy, necessary to bacterial cells maintenance and growth; it uses external organic matter (Exogenous process). The second one (Reaction 2) is related to multiplication of bacterial cells using organic matters. The third one (Reaction 3) uses biomass when the dissolved substrate becomes rare (Endogenous process) and bacteria cells use their own reserves. The kinetics of the endogenous process reaction is relatively low as compared to the exogenous processes.

The packing filling the reactor allows the development of biofilm by its colonization over the available surface area, in which bacterial cells adhere to each other. These adherent cells are frequently embedded within a self-produced matrix of extracellular polymeric substance (EPS) allowing the formation of biofilm (Horan, 2003; Harvey et al., 2011).

It is well known that the performances of bioreactors depends on biofilm growth, which could be influenced by several factors, among others: packing characteristics (Mendoza-Espinoza, 1999; Cheremisinoff, 2002; Prenafeta-Boldú et al., 2008), aeration conditions (Kassab et al., 2010; Jin et al., 2012; Albuquerque et al., 2012), substrate concentration and its nature in wastewater (Amrouche et al., 2011; Chen et al., 2012).

The submerged aerobic fixed-film reactor performances could be assessed by the biodegradation yield (Y). It is expressed as follows:

where: Y, Yield (%) removal of the substrate (in terms of BOD); L0, Initial organic load of the substrate, expressed in BOD (MgO2/L); L, final organic load of the substrate at time t, expressed in BOD (MgO2/L).

The removal performances could also be assessed by calculating biodegradation kinetics constants of organic pollution. In batch reactor, the most significant period in the growth cycle is the exponential growth phase, when the population of biomass is perfectly adapted to the substrate. The first-order model, neglecting endogenous respiration, provides accurate simulations of biodegradation kinetics. It can be written as follows (Cheremisinoff, 2002; Mara, 2003):

where:

t: time (d); kt: first-order BOD biodegradation kinetics constant expressed as (d-1) depending on the temperature according to the following expression:

where: first-order BOD biodegradation kinetics constant at T0, expressed as (d-1): temperature coefficient, equal to 1.032, this value is in the range of those given by Lesouef et al. (1992) and Queinnec et al. (2006).

T: Temperature of the synthetic wastewater expressed in °C; T0: Standard temperature at 20°C.

The integration of equation 2, taking into account equation 3, provide the expression of substrate degradation in time:

The linearization of this equation allows the determination of the constant using semi-logarithmic coordinates according to Equation 5.

This equation was used in this study. Glycerol substrate used is pure. So the COD will be considered almost equal to the BOD (Mara, 2003). Other physicochemical parameters such as conductivity, pH, dissolved oxygen and turbidity could be linked to the assessment of submerged aerobic fixed-film reactors performances (Mendoza-Espinoza et al., 1999; Akin et al., 2005; Albuquerque et al., 2012) and could give some explanations about the efficiency of this bioreactor against wastewater treatment. This work aimed to study the effect of initial concentration of the synthetic wastewater on the adaptability of bacterial cells on a submerged aerobic fixed-film reactor packing on surface area and the biodegradation kinetics; four tests were made with concentrations: 330 MgO2/L (S1), 480 MgO2/L (S2), 860 MgO2/L (S3) and 1120 MgO2/L (S4).

MATERIALS AND METHODS

Experimental setup

Experiments were carried out in a reactor operating in batch mode (Figure 2). It was a cylindrical column, with height of 1 m and diameter of 0.125 m, made of opaque PVC. It was filled with 5 L of the synthetic wastewater. The air was introduced at the bottom of the column through an air flow equal to 10 L/h, by a rectangular diffuser (8 × 1 cm).

The bioreactor was filled with Biocell® packing (Figure 2) with excellent physical characteristics (Table 1). It was supported by a grid placed just above the air sparger at the bottom of the column for maintaining the packing fixed. Another grid was used to fix this packing to avoid its flotation by the effect of crossing air bubbles.

Synthetic wastewaters preparation and experiments conduct

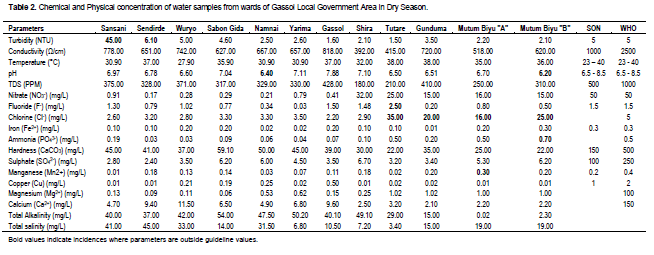

Synthetic wastewaters were prepared in COD/N/P ratio of 100/4/1 (EPA, 1997; Mara, 2003) (Table 2), using distilled water. Pure glycerol was the organic substrate. Salts of sodium nitrate (nitrogensource) and potassium phosphate (phosphorus source) and some oligoelements (FeSO4, MgSO4, MnSO4 and CaSO4) were also added to synthetic wastewaters prepared. Doses of oligoelements were low (Mara, 2003; Jin, 2012).

To initiate the adaptation, inoculation by bacterial flora was made in the reactor. This bacterium was extracted from soil (Mara, 2003; Horan, 2003). Table 3 illustrates the physicochemical characteristics of synthetic wastewaters.

Submerged aerobic fixed-film reactor performances monitoring

Chemical oxygen demand (COD) and turbidity were monitored using a photometer type Palintest 7000. pH and dissolved oxygen were measured using a Hach sensor 40d-HQ -Multi parameters, which can also measure the temperatures of water and air. The conductivity was measured by Orion model 125. For measuring the COD concentrations, samples from the bioreactor were filtered through filters having a pore size of 0.45 µm. For the other parameters, measurements were realized directly in samples.

RESULTS AND DISCUSSION

COD and biodegradation kinetics evolution

COD results are presented in Figure 3. According to the figure, the same appearance was shown in COD curves. In fact, it shows three principal phases. The first slow phase correspond to the adaptation of bacteria cells to the substrate and also to the hydraulic batch mode conditions (adaptation phase). The time of this adaptation increased with the initial concentration as notified by some authors (Amrouche et al., 2011; Dey et al., 2010). This time was 1 day for S1 and S2, 2.5 days for S3 and 3.5 days for S4. After this time, the substrate concentration manifested a slow decrease. The second phase corresponded to the removal of the substrate. This removal depended on initial concentration. In low COD concentration (330 MgO2/L), the time required was 3 days, moreover, this time was 4, 5 and more than 6 days, respectively for 480, 860 and 1120 MgO2/L.

The third phase manifested a deceleration of the substrate concentration decrease. The COD tended to stabilize at times, an endogenous respiration has probably triggered after an almost total removal of the substrate (Reaction 3).

The biodegradation kinetics constants could be determined by linearization of the equation 5 and plotting log (L/L0) against time as shown in Figure 4. Two different slopes of the glycerol biodegradation kinetics for each COD concentration removal have been noted. The first one was slight; it corresponded to the adaptation phase where a little part of substrate was consumed. The second slope was pronounced; it represented the biodegradation phase. The substrate removal was a function of the initial concentration of glycerol. Table 4 shows the values of biodegradation kinetics constants of degradation phase depending on the initial concentration. Biodegradation yields of these tests were illustrated in Table 5.

Both Tables 4 and 5 showed that the adaptability of bacterial cells (quantified by biodegradation kinetics constants and purifications yields) was better at a low initial concentration of glycerol. This adaptability behavior does not depend on the glycerol molecule (not toxic), unlike other tests where it is associated with the toxicity of the substrate when it becomes limited, as found by some authors (Duan, 2011; Marrot, 2006). This result is consistent with the study of Dey et al. (2010). Papadia et al. (2011), also highlighted the influence of the initial concentration of substrate on different biological treatment systems (trickling filter, activated sludge, bioflottation, flow jet aeration) working in continuous hydraulic regime. It has been shown that the increase of the organic load affected adversely the removal rate of the wastewater pollution. Silva et al. (2011) conducted tests to evaluate biodegradation kinetics of winery wastewaters in an aerobic batch, varying substrate concentrations (1, 3, 5 and 7 g/L). The evolution of COD removal efficiency presented a sharp drop of COD concentration at the beginning of the biodegradation curve, better for low concentrations, followed by a gentle drop.

Authors indicated that the adsorption, possibly occurring opposite intermediate adsorption of some compounds before biodegradation, is an important factor that may affect the biodegradation process and lead to exaggerated degradation slopes (Li et al., 2009). Matsuo et al. (2001) indicated that the initial concentration of the substrate influenced the properties of biofilm and its performance of purification. They indicated also that in the presence of heavily loaded waste water, a thick and less dense biofilm is formed; this caused a difficulty in the transfer of nutrient for the development of the bacteria inside the biofilm, unlike weakly charged wastewater.

Turbidity evolution

Turbidity results for the different synthetic solutions are presented in Figure 5. Results illustrated in Figure 4 shows that the turbidity followed the same trend for all initial concentrations tested, except for S1 (330 MgO2/L).The turbidity decreased at the beginning for S2, S3 and S4, and then, it increased to reach a maximum. But for S1, turbidity increased probably because of the quick adaptation of bacteria as mentioned above, inducing an increasing in biomass formation (Reaction 2).

The different synthetic wastewaters have different initial turbidities, from 10 to 30 NTU. This was due to the quantity of matters, especially from soil, added to each synthetic wastewater, despite the filtration of synthetic wastewaters. On the adaptation phase, turbidity decreased probably by physical interception and the adsorption and flocculation of biofilm due to extracellular polymeric substances (EPS) secreted by bacteria (Zhang and Liu, 2005; Hongyuan et al., 2013).

The increase of turbidity coincided with the beginning of the degradation phase. These two processes occurred at the same time according to the Reactions 1 and 2. This increase may be due to some factors: augmentation of biomass quantity, a part of which can be detached by abrasion of biofilm due to the air flow or by gases (CH4, N2, CO2, etc.) released by anaerobic/anoxic processes, generally produced when the thickness of biofilm became high. Turbidities reached a maximum, which depended on the initial concentration (Table 6).

Turbidity results confirm clearly those of COD, and allow the same conclusions concerning the behavior of batch bioreactor (Valentis, 1988; Kwok et al., 1998). So, the turbidity was a monitoring parameter which could characterize the stage of the biological process.

pH evolution

pH experimental results are presented in Figure 6. Figure 6 shows, at the beginning, an increase of pH for S1 and S2 tests, a slight decreased for S3 and a constant evolution for S4. After the adaptation phase, a pH increasing trend was observed for all tests. The pH behavior in test S1 could be probably explained by their rapid kinetics. It could be corroborated by COD and turbidity results of S1.

During biodegradation, the pH measured in synthetic wastewaters resulted from an equilibrium between bacterial cells catabolism process (CO2 formation from Reaction 1) and from the denitrification process (increase of pH), as reported by some researchers (Fabregas, 2004; Akin et al., 2005). It could also be affected by the stripping of CO2 (Cohen et al., 2004, Morales et al., 2013).

To explain pH behavior, the biofilm detachment caused a degradation of biomass protein. Akin et al. (2005) and Fabregas (2004) showed that this increase could be explained by the denitrification which occurred during anoxic phase in a SBR. The noted decrease of DO as shown above limited the oxygen transfer in the synthetic wastewater and promotes the conditions of the denitrification which occurred in the biological matter. The pH could be used to monitor the biological process. Its evolution depended on turbidity and the aeration of synthetic wastewater.

Dissolved oxygen evolution

DO results are illustrated in Figure 7. It has been clearly oxygen decreased continuously in S2 and S3 tests. Whereas, in S4 test, the observed initial DO was low (Table 7). DO increase before a decrease. This behavior can be explained by the viscosity of S4 synthetic wastewater, due to its high concentration (1120 MgO2/L), which prevents an efficient oxygen transfer (Stemmet et al., 2008; Kherbeche et al., 2013). But, during the adaptation phase a little part of substrate was consumed, so a DO increase was observed. After that, the DO decreased because of the substrate consumption by bacterial cells during biodegradation phase (Reaction 1).

The oxygen transfer could also be decreased because of the biological suspended matter, as reported by some authors (Rosenberger, 2003; Germain et al., 2007). It controlled both kLa20 and α-factor. Moreover, biological suspended matter accounted for the effects of the viscosity (Garcia-ochoa et al., 2000; Jin et al., 2001; Rosenberger, 2003). On the other hand, the α-factor was affected by the surfactants through EPS secreted by biological matter. Jimenez et al. (2014) showed a strong depression in bubble rise velocity and mass transfer in the presence of surfactants.

When transferring, oxygen must penetrate through the soluble microbial products (SMP) and then diffuse through the flock matrix (EPS) (Jimenez et al., 2014).

However, during biological process, the substrate could be transformed to some bio products which acted as surfactant agents, and affected the oxygen transfer (Garcia-ochoa et al., 2005; Painmanakul, 2005). So, the DO was correlated with the process biodegradation through its diminution during the process.

CONCLUSIONS

The main conclusions that could be drawn from this study are:

1. The various stages of the process of biological degradation occurring in a batch reactor are the adaptation, the degradation of the substrate and the endogenous respiration.

2. The biological kinetics presents two slopes, the first one is slight and corresponds to the adaptation phase, the second one is accentuated, it corresponds to the biodegradation phase.

3. When the substrate concentration is low, the duration of the adaptation phase is small and the elimination of the substrate is easy.

4. The tests gave excellent results in terms of the abatement rates: 94.2% (S1), 91.7% (S2), 91.8% (S3) and 79.5% (S4) which corroborated with calculated biological kinetics constants (0.407 d-1 (S1), 0.346 d-1 (S2), 0.341 d-1(S3), and 0.232 d-1(S4)). These results confirmed also the good adaptability at low concentrations of substrate.

5. The turbidity was revealed as a great indicator of bacteria metabolism. Its increase coincided with the beginning of the substrate degradation; several factors were acting in the same time: development of bacteria cells in which, a part was detached by abrasion due to the air flow or by the anaerobic/anoxic process occurring when the thickness of biofilm increased.

6. In the same time, the pH increased when the turbidity increased and dissolved oxygen decreased because of aerobic bacteria metabolism, striping of CO2 and increasing in viscosity due to some metabolites produced during biological reaction.

CONFLICT OF INTERESTS

The authors did not declare any conflict of interest.

REFERENCES

|

Akin B, Ugurlu A (2005). Monitoring and control of biological nutrient removal in a sequencing batch reactor. Process Biochem.40:2873-2878. Crossref |

||||

|

Albuquerque A, Makinia J, Pagilla K (2012). Impact of aeration conditions on the removal of low concentrations of nitrogen in a tertiary partially aerated biological filter. Ecol. Eng. 44:44-52. Crossref |

||||

|

Chaudhary DSVigneswaran S, Ngo H, Shim WG, Moon H (2003).Biofilter in Water and Wastewater Treatment. Korean J. Chem. Eng., 20:1054-1065. Crossref |

||||

|

Chen S, Hu W, Xiao Y, Deng Y, Jia J, Hu M (2012). Degradation of 3-phenoxybenzoic acid by a Bacillus sp. PLoS One.7: e50456. Crossref |

||||

| Cheremisinoff NP (2002). Handbook of Water and Wastewater Treatment Technologies. Elsevier. | ||||

|

Cohen Y, Kirchmann H (2004). Increasing the pH of wastewater to high levels with different gases CO2 stripping.Water Air Soil Pollut. 159:265-275. Crossref |

||||

| Dey S, Mukherjee S (2010). Performance and kinetic evaluation of phenol biodegradation by mixed microbial culture in a batch reactor. Int. J. water Environ. Eng. 2:40-49. | ||||

| Duan Z (2011). Microbial degradation of phenol by activated sludge in a batch reactor. Environ. Prot. Eng. 37:53-63. | ||||

| EPA (1997).Wastewater Treatment manuals - Primary, secondary and tertiary treatment. Environmental protection agency. | ||||

| Fabregas TV (2004). SBR Technology for wastewater treatment : suitable operational conditions for a nutrient removal. Thesis. | ||||

|

Garcia-ochoa F, Castro E, Santos V (2000). Oxygen transfer and uptake rates during xanthan gum production. Enzym. Microb. Technol. 27:680-690. Crossref |

||||

|

Garcia-ochoa F, Gomez E (2005).Prediction of gas-liquid mass transfer in sparged stirred tank bioreactors. Biotechnol. Bioeng. 92:761-772. Crossref |

||||

|

Germain E, Nelles F, Drews A, Pearcec M, Kraumeb M, Reida E (2007). Biomass effects on oxygen transfer in membrane bioreactors. Water Res. 41:1038-1044. Crossref |

||||

|

Harvey G, Hasibul H, Dipesh D, Charles M, Hung YT (2011). Biofilm Fixed Film Systems. Water. 3:843-868 Crossref |

||||

| Hongyuan L, Wenchao G (2013). Research on biological aerate filter with volcanic filter for pretreatment of micro-polluted source water in lower temperature. Afr. J. Microbiol. Res. 7:4794-4800. | ||||

| Horan N (2003). Handbook of Water and Wastewater Microbiology. Elsevier. | ||||

|

Jin B, Yu Q, Yan X, Van Leeuwen J (2001). Characterization and imporvement of oxygen transfer in pilot plant external air-lift bioreactor for mycelial biomass production. MicrobBiotechnol. 17:265-272. Crossref |

||||

|

Jin Y, Ding D, Feng C, Tong S, Suemura T, Zhang F (2012). Performance of sequencing batch biofilm reactors with different control systems in treating synthetic municipal wastewater.Bioresour. Technol. 104:12-18. Crossref |

||||

|

Kassab G, Halalsheh M, Klapwijk A, Fayyad M, Van Lier JB (2010). Sequential anaerobic-aerobic treatment for domestic wastewater - a review. Bioresour. Technol. 1013299. 101:3299-3310. Crossref |

||||

|

Kherbeche A, Milnes J, Jimenez M, Dietrich N, Hébrard G, Lekhlif B (2013). Multi-scale analysis of the influence of physicochemical parameters on the hydrodynamic and gas–liquid mass transfer in gas/liquid/solid reactors. Chem. Eng. Sci. 100: 515-528. Crossref |

||||

|

Kwok W, Picioreanu C, Ong S, Van Loosdrecht MC, Ng W, Heijnen J (1998). Influence of biomass production and detachment forces on biofilm structures in a biofilm airlift suspension reactor. Biotechnol. Bioeng. 58:400-407. Crossref |

||||

| Lesouef A, Payraudeau M, Rogalla F, Kleiber B (1992). Optimizing nitrogen removal reactor configurations by on-site calibration of the IAWPRC activated sludge model. Water Sci. Technol. 25:105-123. | ||||

|

Li WW, Li XD, Zeng KM (2009). Aerobic biodegradation kinetics of tannic acid in activated sludge system. Biochem. Eng. J. 43:142-148. Crossref |

||||

| Mara D (2003).Domestic Wastewater treatment in developing countries. | ||||

|

Marrot B, Barrios-Martinez A, Moulin P, Roche N (2006). Biodegradation of high phenol concentration by activated sludge in an immersed membrane bioreactor. Biochem. Eng. J. 30:174-183. Crossref |

||||

| Matsuo T, Hanaki K, Takizawa S, Satoh H (2001). Advances in Water and Wastewater treatment technology - Molecular technology, nutrient removal, sludge reduction and environmental health. | ||||

|

Mendoza-Espinoza L, Stephenson T (1999). A review of biological aerated filters (BAF) for wastewater treatment. Environ Eng Sci. 16:201-216. Crossref |

||||

|

Morales N, Boehler MA, Buettner S, Liebi C, Siegrist H (2013). Recovery of N and P from urine by struvite precipitation followed by combined stripping with digester sludge liquid at full scale.Water. 5:1262-1278. Crossref |

||||

| Painmanakul P (2005). Analyse locale du transfert de matière associé à la formation de bulles générées par différents types d'orifices dans différentes phases liquides Newtoniennes : étude expérimentale et modélisation. Thèse de Doctorat. | ||||

|

Papadia S, Rovero G, Fava F, Di Gioia D (2011). Comparison of different pilot scale bioreactors for the treatment of a real wastewater from the textile industry. Int. Biodeterior. Biodegradation. 65:396-403. Crossref |

||||

|

Prenafeta-Boldú FX, Illa J, van Groenestijn JW, Flotats X (2008). Influence of synthetic packing materials on the gas dispersion and biodegradation kinetics in fungal air biofilters. Appl. Microbiol. Biotechnol. 79:319-327. Crossref |

||||

|

Queinnec I, Ochoa J, VandeWouwer A, Paul E (2006). Development and calibration of a nitrification PDE model based on experimental data issued from biofilter treating drinking water. Biotechnol.Bioeng. 94:209-222. Crossref |

||||

| Silva F, Pirra A, Sousa J, Arroja L, Capela I (2011). Biodegradation Kinetics of winery wastewater from port wine production. Chem. Biochem. Eng. 25:493-499. | ||||

|

Stemmet CP, Bartelds F, Van Der Schaaf J, Kuster BFM, Schouten JC (2008). Influence of liquid viscosity and surface tension on the gas–liquid mass transfer coefficient for solid foam packings in co-current two-phase flow. Chem. Eng. Res. Des. 86:1094-1106. Crossref |

||||

| Valentis G (1988). Epuration par cultures fixées sur support géotextile. Ecole Nationale des ponts et chaussées. Thèse de Doctorat. | ||||

| Zhang T, Liu X (2005). Effect of bidosicai activated carbon filter on treatment of micro-polluted source water. China Water and Wastewater. 21:39-40. | ||||

Copyright © 2024 Author(s) retain the copyright of this article.

This article is published under the terms of the Creative Commons Attribution License 4.0