ABSTRACT

The physical properties of pineapple pomace are important in designing and fabricating equipment and structures for handling, transporting, processing and storage. The study was conducted to investigate some physical properties of pineapple pomace at various moisture levels. The experiment was used to evaluate the physical properties at different pineapple pomace/cassava flour ratio mash (5:1, 6:1 and 7:1) and the moisture content of the mash (12.36, 15.66, 19.58, 22.70 and 26.26%). In the same moisture range, the bulk density increased from 427 to 679 kg/m3. The coefficient of friction of pineapple pomace flour and cassava at various mixing ratio increased linearly (p<0.05) for all the surfaces and varied with structural surface in the moisture range of 12.36 to 26.26% (dry basis). The maximum and minimum values of coefficient of friction were obtained on the surface of wood and stainless steel respectively. Pineapple pomace moisture content effect was statistically significant (p<0.05) on all properties investigated while baseline data were generated for the development of necessary handling and processing equipment. The results encourage value addition to the industrial waste while reducing environmental pollution.

Key words: Designing, processing, mash, surface, steel.

Pineapple is the world's most popular non-citrus tropical and subtropical fruit known for its excellent sensory attributes and nutritional composition (Azevedo et al., 2007). It shows great potential for the processing industry due to its high contents of vitamins C and A. The residues from its processing called pineapple pomace constitute heterogeneous mixture of husks and skins, accounting for 4 to 12% and 15 to 25%, respectively of the total mass of pineapple produced (Mantovani et al., 2004; Rogério et al., 2007). Traditionally, cassava is mostly used as human food but it is also an important raw material in its various forms for many textile, paper, and pharmaceutical industries; battery manufacturers need starch and its derivatives. The substitution of wheat or maize flour partially with cassava flour and production of cassava chips and pellets for animal feed are other areas of utilization with some potential significant in Nigeria.

The present methods of handling and processing the pineapple pomace are very slow and full of drudgery with a lot of wastage. Therefore, it is necessary to develop better means of processing the pineapple pomace into useful products using suitable machines and equipment. Knowledge of its physical properties is very useful to machine design. The increased awareness of the nutritive and economic benefits pineapple pomace provides in livestock production must be taken into consideration to avoid potential market saturation. Most of the investigations show that the physical properties of agricultural products are moisture dependent. Although most research work in the field of the coefficient of friction of agricultural materials is related to grains, some literature was found regarding the static coefficient of friction, adhesion coefficient, and cohesion coefficient of forage materials. Coefficients of friction of grains and forage materials are significantly affected by material moisture content. Several researchers (Sadiku and Bamgboye, 2014; Aviara et al., 2012; Oduntan et al., 2010; Dash et al., 2008; Naderiboldaji et al., 2008; Afzalinia and Roberg, 2007; Owolarafe et al., 2005) studied the physical properties of different agricultural products for the above purpose. Therefore, in order to increase supply, it is necessary to modernize production techniques and optimize processing conditions (Audu et al., 2004). To achieve this, adequate information on the properties of pineapple pomace is required for the design of equipment for its. No work however, appears to have been carried out on the moisture dependence of physical properties of this important fruit pomace. Data of physical properties of pineapple pomace were required as input to the design calculations of the process equipment of this materials. Therefore, this study investigated the influence of moisture content on the properties of pineapple pomace for future design of processing equipments.

Sample preparation

The fresh pineapple pomace sample, rich in water (about 90%) was obtained from a juice processing plant (Funman Agricultural Products Ind. Ltd, Moor Plantation Ibadan). Two groups of 250g sub-samples of the pineapple pomace were used for the determination of the proximate. Analyses of the samples were carried out in triplicate according to AOAC standardized procedures and the average values of the observation were documented.The pineapple pomace was dried in a fluidized bed dryer (Fexod AS 230, Nigeria) at temperature of 65°C to avoid changes in the functional properties and proteins with air velocity of 5.0 m/s in a forced convection thin layer dryer with thickness of between 10 and 15 mm. The dried samples were ground to powder through a screen plate in the disc mill (Model 206, Fexod disc mill, Nigeria).

Experimental procedure

Samples of the pineapple pomace and cassava flour as a binder were ground separately with a 3 mm screen disc mill (Model 206, Fexod disc mill, Nigeria). Particle size distribution of the ground samples was determined separately according to ASABE Standard S269.3 (ASABE, 2003). Hundred gram of the material was placed on the top sieve of nest of successively smaller sieves. The set consists of six test sieves and a pan with aperture sizes ranging from 0.1 to 2 mm (Endecotts Limited, London). The nest of test sieves was clamped on a shaker for 10 min after which the mass of material retained on each sieve was measured on a digital scale (Model Ultra – 75, U.S.A). Cumulative weight of each fraction was obtained as percentage of total mass of the sample.

Bulk densities of the wet pineapple pomace, dried pineapple pomace and cassava flour were determined as recommended by ASABE S269.4 (ASABE, 2003). A container was filled with pomace using a funnel, without compacting the content. The material was leveled with the top surface of the container and weighed. The mash bulk densities were obtained from the ratios of the measured masses of samples in the container to the volume of the container. Five measurements of each experimental run were taken to obtain the average values and standard deviations.

The moisture content of the pineapple pomace and cassava flour was determined separately using the oven method as described in Equation 1 (ASABE, 2003). Moisture cans were weighed on an electronic weighing machine (Model Ultral-75, U.S.A) and recorded.

MC = [(Wi - Wf)/ Wi]100% (1)

Where, MC = moisture content; Wi = initial weight; Wf = final weight.

The coefficient of sliding friction of the samples was determined on four various surfaces (polished wood, mild steel, galvanized steel and stainless steel) at different pineapple pomace and cassava flour ratio. The incline plane was gently raised and the angle of inclination at which the sample start to slide was read off the protractor with sensitivity of one degree. The tangent of the angle was recorded as the coefficient of friction.

The static angle of repose of the samples was determined using a cylindrical container open at both ends and placed on a flat surface (Aviara et al., 1999). It was filled from the top with samples. The cylinder was then lifted up gradually allowing the sample to flow and form pile. The angle of repose was calculated from the measurements of the vertical depth and radius of spread of the sample. This was replicated five times.

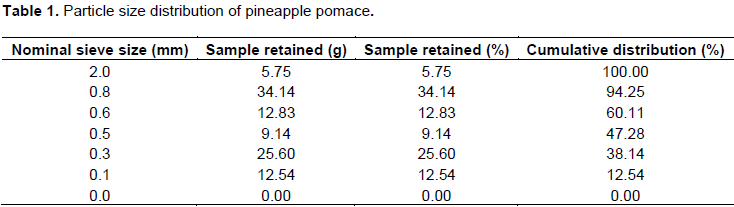

Particle size distribution

The particle size distribution of the pineapple pomace sample after grinding is shown in Table 1. It is apparent that a large part of the pomace flour was retained on the 0.6 and 0.8 mm nominal sieve size which was about 50% of the total sample. Some samples are quite fine on the 0.1 mm sieve size. Similar results had been observed in the particle size determination of peanut pomace (Fasina, 2008). The result shows that pineapple pomace particles have larger diameter which might affect the texture and uniformity of the product. According to Frame (1994), larger particles of material have less contact area with the barrel of the extruder during the period when are convey along the screw and are less affected by the barrel temperature than fine particles.

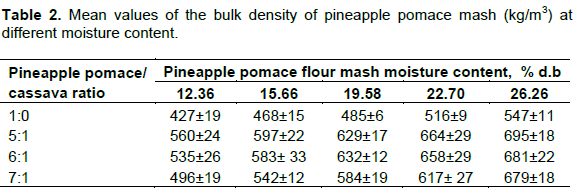

Bulk density

The variation of pineapple pomace/cassava flour mash ratio bulk density with moisture content is shown in Table 2. The bulk density of pineapple pomace/cassava flour mash ratio at 1:0, 5:1, 6:1 and 7:1 increased from 427 to 547kg/m3, 560 to 695 kg/m3, 535 to 681 kg/m3 and 496 to 679 kg/m3 as their moisture contents increased from 12.36 to 26.26% (db) respectively which indicated low bulk density. From this table, it can be seen that the bulk density of the pineapple/cassava mash ratio is lower at higher pineapple pomace inclusion rate of 7:1 than that of higher cassava flour inclusion rate of 5:1 within a similar moisture range.

The relationship existing between pineapple pomace/ cassava flour bulk density and moisture content can be expressed with the following equations:

1:0

1:0= 8.24

M+ 329.47;

R2 = 0.9829

5:1

5:1= 9.66

M + 442.43;

R2 = 0.9976

6:1

6:1= 10.55

M+ 414.06;

R2 = 0.9743

7:1

7:1= 13

M+ 331.45;

R2 = 0.9910

Where:

1:0,

1:0, 5:1,

5:1, 6:1,

6:1, 7:1

7:1 - bulk densities (kg/m

3) of pineapple pomace/cassava flour mash ratio 1:0, 5:1, 6:1 and 7:1 respectively.

M = moisture content (%)

A similar observation was made by Kumar et al. (2010) as they studied the bulk density of fruit pomace. Frame (1994) reported that a high volumetric capacity screw is required for the design of extruder with low bulk density material for their conveying volume rather than pumping ability. It was reported that actual length of feed zone on the screw shaft depends on the bulk density of the pineapple pomace (Frame, 1994).

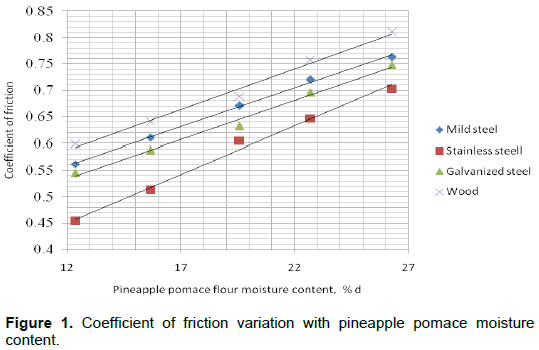

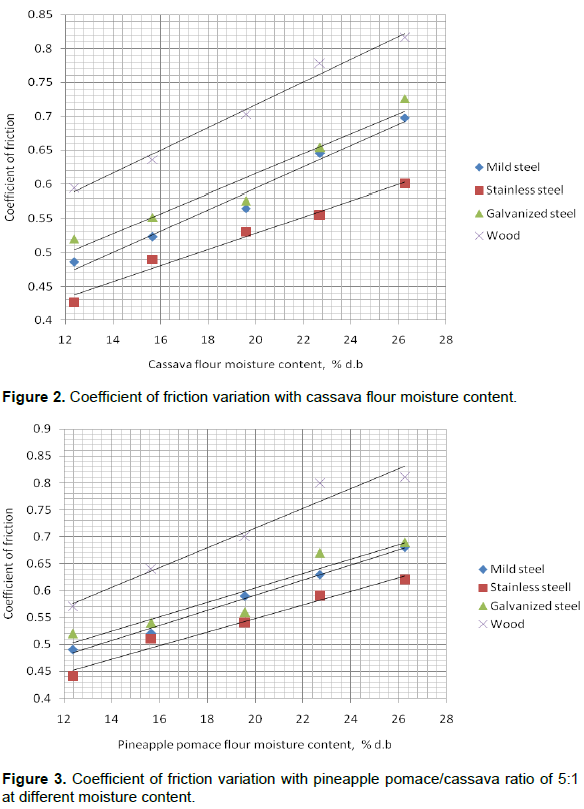

Coefficient of sliding friction

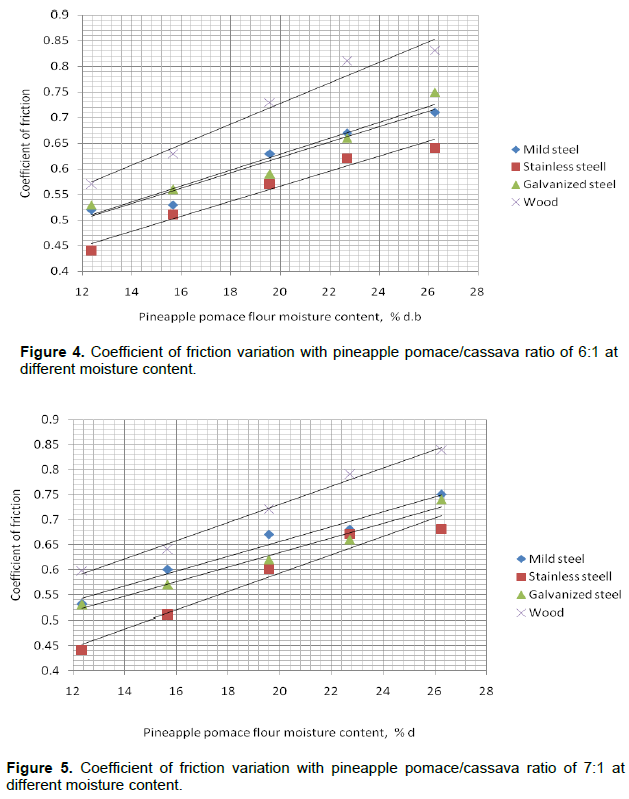

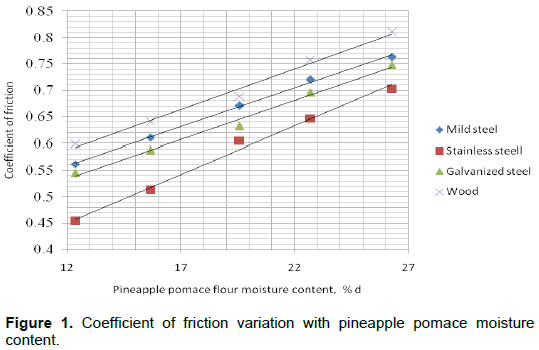

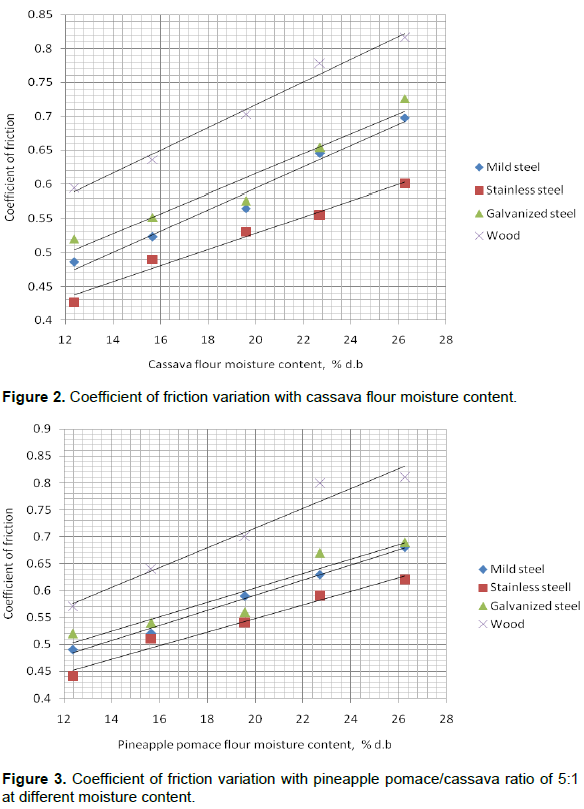

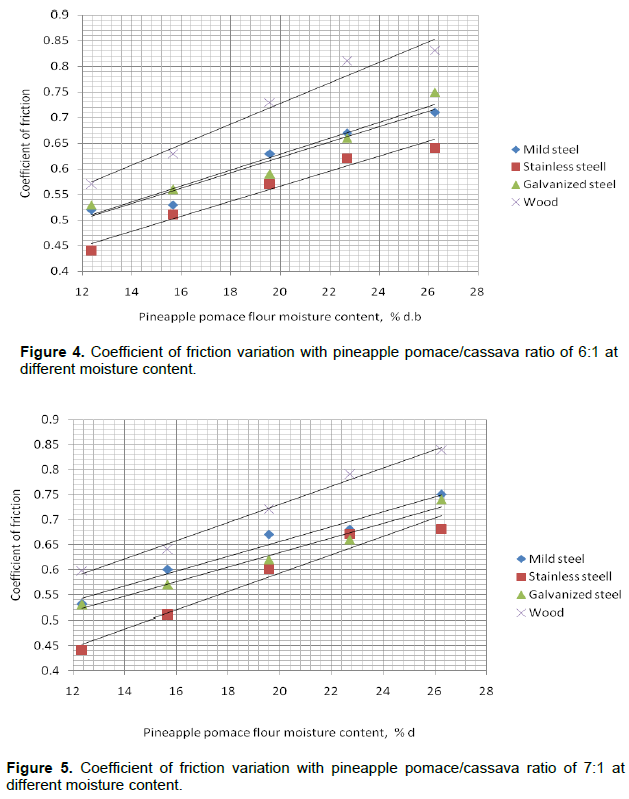

The mean results obtained for frictional properties of pineapple pomace flour and cassava flour at different inclusion ratio on four structural surfaces at different moisture levels (12.36 to 26.26%) are given in Figures 1 to 5. The effect of moisture content on the coefficient of friction for the inclusion ratio of pineapple-cassava on mild steel, stainless steel, galvanized steel and wood surfaces are significant. Coefficient of friction followed an increasing trend with increasing moisture content as shown in all the figures.

The result indicated that coefficient of friction was greater on the wood surface and galvanized steel than mild and stainless steel. The value obtained for pineapple pomace sample was higher than that of cassava flour (Figures 1 and 2). This showed that pineapple pomace flour was not smooth as cassava flour. Figures 3 to 5 showed that coefficient of friction increased with pineapple pomace inclusion rate. The coefficient of friction of pineapple pomace flour and cassava at various mixing ratio increased linearly (P<0.05) for all the surfaces and varied with structural surface in the moisture range of 12.36 to 26.26% (db). The maximum value of 0.81and 0.82 were obtained on the surface of wood for pineapple pomace and cassava flour res-pectively. Minimum value of 0.45 and 0.43 were obtained on the surface of stainless iron sheet for pineapple pomace and cassava flour respectively. This result was in good agreement with the results reported for alfalfa and similar materials in the literature (Shinners et al., 1991; Ling et al., 1997; Mani et al.,2003; Afzalinia and Roberge, 2007). Zhang et al. (1994) found that the coefficient of friction of wheat on a corrugated steel surface increased with an increase in moisture content. Ling et al. (1997) stated that the static and sliding coefficients of friction of wood ash increased with an increase in ash moisture content. Chandrasekar and Viswanathan (1999) showed that the coefficient of friction of arabica and robusta (coffee) parchments on various surfaces increased with an increase in moisture content in the range of 9.90 to 30.6% (wb). Aviara et al. (1999) reported a range of 0.41 to 0.98 for the coefficient of static friction of guna seeds in the moisture range of 4.70 to 39.3% (db). The relationship between the coefficient of friction and moisture content can be expressed for different structural surfaces were linear using the following equations:

fmp= 0.014M + 0.382; R2 = 0.948

fsp= 0.018M + 0.232; R2 = 0.934

fgp= 0.014M + 0.547; R2 = 0.99

fwp= 0.015M +0.402; R2 = 0.988

fmc= 0.015M + 0.218; R2 = 0.975

fsc = 0.011M+ 0.291; R2 = 0.977

fgc = 0.014M + 0.322; R2 = 0.937

fwc = 0.016M + 0.380; R2 = 0.987

Where fmp, fsp, fgp, fwp, fmc, fsc, fgc, fwc - the static coefficients of friction of pineapple pomace and cassava on mild sheet, stainless sheet, galvanized sheet and wood respectively. M - moisture content (%)

Similar findings were reported for baobab fruit pulp powder (Adekunle et al., 2013). The frictional properties are useful in designing partitions, lining materials and in bulk transportation of agricultural products in trucks (Jahromi et al., 2008). However, the coefficient of static friction of agricultural materials depends on the moisture content of produce at the time of testing (Dutta et al., 1988).

The following conclusions were drawn from the results of this research:

(1) The particle size distributions of the dried pineapple pomace sample after grinding have larger diameters.

(2) The bulk density of pineapple pomace/cassava flour mash at inclusion ratio indicated low bulk density. Low bulk density will increase the packing density; reduce the cost of transport and storage space. High efficient machine can be developed with low bulk density.

(3) The highest coefficient of static friction and angle of repose for pineapple pomace flour and cassava at various mixing are on wooden surface and the lowest on stainless sheet surface and therefore, stainless it could be used to minimize abrasion damages and for the construction of processing machine to improve efficiency.

(4) The results encourage value addition to the industrial waste and reduce environmental pollution.

The authors have not declared any conflict of interests.

REFERENCES

|

American Society of Agricultural and Biological Engineers (ASABE) Standard S269.4. (2003). Cubes, pellets and crumbles-definitions and methods for determining density, durability, and moisture content. St. Joseph, M1.

|

|

|

|

Afzalinia S, Roberge M. (2007). Physical and mechanical properties of selected forage materials.Canadian Biosystems Engineering. Canada 49:2.23-2.27.

|

|

|

|

|

Audu I, Oloso A. Umar B (2004). Development of concentric cylinder locust bean dehuller. Agric. l Eng. Int. CIGR J. Sci. Res. Dev. 6:1-11.

|

|

|

|

|

Aviara NA, Gwandzang M I, Haque M A (1999). Physical properties of guna seeds. J. Agric. Eng. Res. 73:105-111

Crossref

|

|

|

|

|

Aviara NA, Onuh OA, Ehiabhi SE (2012). Influence of moisture content and loading orientation on some mechanical properties of Mucuna flagellipesnut. Res. Agr. Eng. 58:66-72.

|

|

|

|

|

Azevedo P, Souza C, Silva B, Silva V (2007). Water requirements of pineapple crop grown in a tropical environment, Brazil. Agric. Water Manage. 88:201-208.

Crossref

|

|

|

|

|

Bamgboye AI, Adejumo OI (2010). Thermal properties of Roselle seed. Int. Agrophys. 24:85-87.

|

|

|

|

|

Chandrasekar V, Viswanathan R (1999). Physical and thermal properties of coffee. J. Agric. Eng. Res. 73(3):227-234.

Crossref

|

|

|

|

|

Dash A K, Pradhan R C, Das L M, Naik S N (2008). Some physical properties of simarouba fruit and kernel. Int. Agrophys. 22: 111-116.

|

|

|

|

|

Dutta SK, Nema VK, Bhardwaj RK (1988). Physical properties of gram. J. Agric. Eng. 39:259-268.

Crossref

|

|

|

|

|

Jahromi MK, Mohtasebi SS, Jafari, ARM, Rafiee S (2008). Determination of some physical properties of date fruit (cv.Mazafati). J. Agric. Technol. 20:1-9.

|

|

|

|

|

Ling Q, Wilhoit JH, Flood CA (1997). Static and kinetic friction coefficients of wood ash on stainless steel. ASAE Paper No. 976020. St. Joseph, MI: ASABE.

|

|

|

|

|

Mantovani JR, Corrêa MCM, Cruz MCP, Ferreira ME, Natale W (2004). Use of fertilizante de resíduo da indústria processadora de goiabas. J. Braz. Fruitcult. 26:339-342.

|

|

|

|

|

Owolarafe OK, Olabige MT, Faborode MO (2005). Physical and mechanical properties of two varieties of fresh oil palm fruit. J. Food Eng. 78:1228-1232.

Crossref

|

|

|

|

|

Naderiboldaji M, Khadivikhub A, Tabatabaeefar A, Ghasemi VM, Zamani Z (2008). Some physical properties of sweet cherry (Prunusavium L.) fruit. American- Eurasian J. Agric. Environ. Sci. 3:513-520.

|

|

|

|

|

Sadiku OA, Bamgboye AI (2014). Moisture dependent mechanical and thermal properties of Locust bean (Parkiabiglobosa). Agric Eng. Int: CIGR J. 16(1):99-106.

|

|

|

|

|

Oduntan OB, Koya OA (2015). Effect of speed, die sizes and moisture contents on durability of cassava pellet in pelletizer. Res. Agric. Eng. 61:35-39

Crossref

|

|

|

|

|

Zhang Q, Britton MG, Kieper RJ (1994). Interactions between wheat and a corrugated steel surface. Trans. ASAE 37(3):951-956.

Crossref

|

|