ABSTRACT

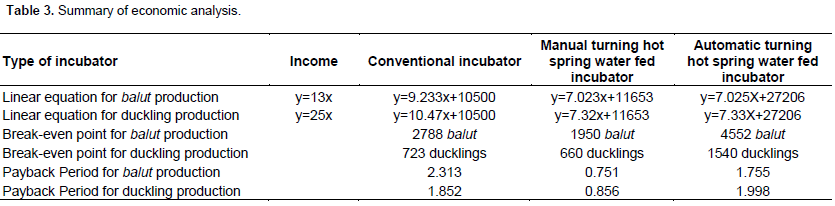

The economic analysis of a manual and automatic turning hot spring incubator developed at the University of the Philippines-Los Baňos, Laguna Province, Philippines, was studied by comparing its performance with the conventional electrical incubator. This research can help small-scale farmers by reducing operational cost and increasing profitability. To determine the feasibility, undiscounted and discounted measures were used. For undiscounted measures, the break-even point (BEP) and payback period (PBP) for the conventional electrical incubator, manual and automatic turning hot spring incubator were 2788, 1950 and 4552 balut; and 2.31, 0.751 and 1.755 years for balut production; 723, 660 and 1540 ducklings; and 1.852, 0.856 and 1.998 years for duckling production, respectively. For the discounted measures, benefit-cost ratio (BCR), net present value and internal rate of return (IRR) for the conventional electricity incubator were 1.07, 1.36 and 1.20; ₱4176.88, ₱34359.81 and ₱22357.39; and 7.16, 36.44 and 20.35, respectively, for balut production and 1.15, 1.44 and 1.16; ₱6264.42, ₱28320.29 and ₱12740.51; and 15.15, 43.78 and 15.88, for ducklings production, respectively. Finally, the outcome of this research can be adopted by balut producers that have access to hot spring. The hot spring manual turning incubator was the most feasible incubator for balut production than the conventional incubator.

Key words: Hot spring incubator, conventional, manual, automatic, ducklings, economic analysis, balut.

At present, there are more than 1.3 billion people worldwide that do not have access to electricity and most of them are concentrated in Africa and Southern Asia (Fontaine et al., 2016). Due to the unequal demand and supply of electricity, people are finding alternative means of energy source. However, geothermal energy is free and environment friendly source of thermal energy. The geothermal energy is already in the form of heat. It can be used as alternative source of heat in agricultural and industrial processes. One of the agricultural applications of heat is incubation of poultry eggs. About 80% of the total duck production in the world is concentrated in Asia (Chang et al., 2006). The ducks are raised alongside rice farming and fish farming in Asia. In Laguna Province, ducks are raised in the range of 800 to 45,000 heads (Atienza et al., 2015). In the Philippines, the duck industry is dominated by balut (partially hatched embryos) production and by smallholder production that accounts for more than 75% of total duck output (Dagaas and Chang, 2004). Balut is fertilized duck egg that has been incubated for a period of 14 to 18 days then steamed or cooked for about 20-30 min for human consumption (Magat, 2015).

These duck eggs are usually incubated in conventional electrical incubators. With the demand and availability of electricity,

balut producers are faced with a problem of continuous electricity By the end of the first quarter of the 21th century, the supply of oil will reach its peak and will begin to decline as predicted by energy experts. The increase in the demand and reduction in the supply will lead to a significant increase in the price of oil (

Fanchi, 2005). Diversification of fuel sources is imperative to address the energy security, climate change and sustainable development issues; therefore, it is essential to address the energy crisis through the extensive utilization of abundant renewable energy resources, such as biomass, biogas, wind, hydro, solar and geothermal energy (Bhutto et al., 2011). Geothermal energy is the energy contained as heat in the Earth’s interior (Barbier, 2002). It energy refers to the heat within the Earth that generates geological phenomena on a planetary scale (Dickson et al., 2013). Geothermal energy is one of the oldest, most versatile and also most common form of utilization of renewable energy (Abbas et al., 2014).

Los Baňos City is located between the northern part of Mt. Makiling and north shore of Laguna de Bay. It is in Laguna Province, Philippines. In the province of Laguna, which is located in Luzon Island, Philippines, tourism development is expected to increase the demand for groundwater resources. Los Baňos lacks major commercial core. In 2014, there were 42 hot spring resorts registered in Los Baňos. Because of the hot spring resorts, Los Baňos is also recognized as a tourist destination. Mostly, the hot springs found were located in the barangays (villages) of Lalakay, Tadlac, Bambang and Baybayin. Groundwater is significant for domestic, commercial and industrial uses in urban and rural development. Groundwater is often tapped as water supply because of its quality, reducing the costs of treatment as compared to surface water sources and its reliability, especially during drought or extended dry periods (Jago-on et al., 2017).

By replacing the electrical heater with hot spring heat exchanger, the operational cost of the hot spring incubator (manual and automatic turning) was less than the conventional electricity incubator (locally manufactured in the Philippines). The hot spring heated the air through a heat exchanger and maintained optimum incubating temperature within the incubator. This research addressed issues such as replacing conventional source of energy with non-conventional, renewable or alternative source. The non-conventional, renewable or alternative source of heat lowered the operational cost of incubating duck eggs which increases the profits of small scale farmers in Los Baňos, Laguna, Philippines. This deemed it necessary to test and evaluate the economic feasibility of a small scale hot spring incubator (Figure 1) and compared the manual and automatic turning hot spring incubator with the conventional electricity incubator.

Experimental set-up

A potential site was located and tested to obtain the conditions of the site such as the flow rate of the hot spring to the surface, temperature of the hot spring, ambient temperature and the wet bulb temperature. The potential site selected was located at Baranggay Malinta, Los Baños with coordinates 14° 10’ 55.91” N and 121° 13’ 36.49” E. The small-scale hot spring incubator (manual and automatic turning) with capacity of 165 duck eggs was designed, tested and evaluated for economic feasibility for balut and duckling production in Los Baňos, Laguan Province, Philippines. Economic analysis of the hot spring incubator was evaluated on two settings: (a) manual turning hot spring incubator and (b) automatic turning hot spring incubator. These two settings of the hot spring incubator were compared with the (c) conventional electrical incubator which was locally manufactured in the Los Baňos area.

Separate test was conducted at a local balutan (a place where baluts are produced) to compare the performance of the conventional incubator with the hot spring incubator at two different settings (manual and automatic turning). The test consists of three replicate and sampling on the candling of duck eggs in the incubator including the entire population. All the duck eggs in the incubator were first candled to evaluate the fertile and infertile three days after being placed in the incubator. The second candling was 19 days after the duck eggs were placed in the incubator to evaluate the balut, penoy and dead egg embryos (balutability). For the hatchability, the hatched and unhatched eggs were evaluated 28 days after incubation. The test and evaluation on the performance was based on the data collected on the total number of fertile eggs, balut incubated, penoy, dead egg embryos and duck eggs hatched.

Descriptive statistics was used to determine the mean, maximum and minimum of the performance parameter. The parameters for evaluate were fertility duck eggs used for the experiment, balutability and hatchability. The economic analysis for the feasibility of the research was also conducted using undiscounted (break-even point-BEP and the payback period-PBP) and discounted measure (benefit-cost ratio-BCR, net present value-NPV and internal rate of return-IRR) to select the most feasible incubator for balut and duckling production in Los Baňos, Laguna Province, Republic of the Philippines. The assumptions, rates and prices were based on the actual setting of the research samples which were collected from duck framers, actual transportation cost, rates and the local market in Los Baňos.

Parameters of evaluation

Balutability: Balutibility is the percentage of number of fertile eggs to successfully incubate for the period of the 18 day period divided by the number of fertile eggs. The fertile eggs were the eggs which embryo developed at three days after placing in the incubator at first candling. The equation used for the computation of the balutability as described by was:

Where B is the balutability in %.

Hatchability: Hatchability is the percentage of fertile eggs to hatch divided by the total number of fertile eggs. The equation used for the computation of hatchability is:

Where H is the hatchability in %.

Electricity consumed per day: Electricity consumed per day is amount of electricity consumed in a day (24 h) as shown in Equation 3.

Electricity consumed = final reading - initial reading (4)

Electricity consumed per day is amount of electricity consumed in a day (24 h) in kW/day.

Economic analysis

The economic analysis took into consideration, the estimated cost of the hot spring incubator when on automatic set-up and manual set-up. The results of the balutability, hatchability and electrical consumption of the incubator were used to analyze the feasibility of the study by comparing the hot spring incubator with the conventional incubator. The economic analysis also took into consideration, the actual prices in the market at the time of the study. The economic analyses used were break-even point (BEP) and payback period (PBP) for undiscounted measure and benefit-cost ratio (BCR) and internal rate of return (IRR) for discounted measure.

Undiscounted measures incubators worth

1. Break-even point: The break-even point is the point where neither profit nor loss is incurred. The incubator with the lowest break-even point was selected as the best (Resurreccion et al., 2006).

Annual fixed cost + unit available cost (x) = unit benefit (5)

Where x is the number of units for break-even point.

2. Payback period: The payback period is the period for recovering the initial investment cost plus the operation cost or the initial investment divided by the average annual net benefits. The incubator with the shortest payback period is the preferred (Resurreccion et al., 2006).

Where n is the number of yields per year.

Discounted measure on incubators worth: The discounted measures involve translating the future values of cash flow into present worth. Discounted measures of economic analysis are more preferred than the undiscounted ones.

1. Benefit-cost ratio (BCR): For the discounted measure of benefit-cost ratio, the investment is said to be profitable if it is equal to 1 or greater than 1 (BCR≥1). The equation of the benefit–cost ratio can be expressed as (Miller and Levy, 1998):

Where BCR is the benefit cost ratio; r is the rate of interest in %; B is the income at a particular time, ₱; C is the cost at a particular time, ₱; and i is a particular period in year.

2. Net present value (NPV): Net present value is computed by finding the difference between the present worth of benefit stream less the present worth of cost stream. The NPV was computed using Equation 9 (Resurreccion et al., 2006):

3. Internal rate of return: The internal rate of return criterion indicates that an investment should be carried out if that rate of discount would not make the present value of all revenues less at all cost, equal to zero, to be higher than an appropriate interest rate (Turvey, 1963). It is the maximum interest that a project can pay for the use of resources if the project is to recover its investment and operating cost and still break-even. The internal rate of return was computed using interpolation in Equation 10 (Resurreccion et al., 2006):

Where, IRR is the internal rate of return; LIR is the lower interest rate in %; HIR is the higher interest rate in %; NPV is the net present value.

Performance of hot spring incubator

The average temperature of the hot spring was 41.49°C with the maximum and minimum temperatures of 41.45 and 41.54°C, respectively. The analysis of variance revealed that the temperature of the hot spring was significantly stable. The temperature and relative humidity recorded during the incubation period were within the maximum and minimum range recommended for duck egg incubator-temperature range of 37.5 to 39.7°C with the relative humidity of 45 to 70% (Paras, 2011). Due to several reasons beyond the scope of this research, the candling of the duck eggs was conducted 3 days after being placed in the incubator before manually sorting the fertile eggs from the infertile one. Candling is the process for sorting infertile eggs from fertile ones or observing the development of the egg. The average fertility of the duck eggs placed in the hot spring incubator was 87.79%.

The same batch of eggs were used for balut (incubation for 19 days) and hatching. The average balutability and hatchability were 99.31 and 62.5%, respectively as shown in Table 1. For the conventional electrical incubator, the fertility was 95.56% while the balutability and hatchability were 100 and 67% respectively. The electrical consumption of the incubator was 6.3 kW-hour and that consumed per day was 0.225 kW-hour/day. At this power rating, the electricity estimated to incubate a duck egg was 0.382 kW. On the other hand, the automatic turning consumed 5.01 kW–hour over the period of 22 days with the power rating of 9.48 W and that consumed per day was 0.288 kW. At this power rating, the electricity estimated to incubate a duck egg for the period of 28 days was 0.387 kW/egg.

Feasibility of hot spring incubator

For the assumption, all data collected were based on the actual prices of items and rates at the time of the research as shown in Table 2. Considering the hot spring incubator (manual and automatic turning hot spring incubator), the fertility, balutability and hatchability were 87.79, 99.31 and 62.5%, respectively, with the capacity of conventional electricity incubator of 90 eggs and the capacity of the hot spring incubator of 165 eggs.

Feasibility using undiscounted measures

The economic analysis of the conventional, manual turning and automatic turning hot spring water fed incubator at the break-even points were at 2788, 1950 and 4552 balut when used for balut production and 723, 660 and 1540 ducklings when used for hatching, while the payback period were 2.313, 0.751 and 1.755 years for balut production and 1.852, 0.856 and 1.988 years for duckling production, respectively, as shown in Table 3. When comparing the manual and automatic turning hot spring water fed incubator with the conventional incubator economically, it is clear that the hot spring manual turning incubator is the best of the three incubators since it is has the lowest break even and the shortest payback period.

The two setting of incubators (manual and the automatic turning hot spring incubators) and the conventional electricity incubator were all feasible considering the payback period. For both balut and ducklings production, the manual turning hot spring incubator was the most feasible with the payback period of 0.751 and 0.856 year, respectively. The break-even point analysis revealed manual turning hot spring incubator as the incubator with the minimum break-even point of 1950 balut and 660 ducklings. By further analyzing the beak-even point by batch placed in the incubator as compared to pieces as shown in Table 4, the manual turning incubator used for balut production is the most feasible with the minimum break-even point at 12 batches of duck eggs in the incubator as compared to the manual turning hot spring incubator with break-even point at 19 batches for duckling production as shown in Table 4.

Feasibility using discounted measures

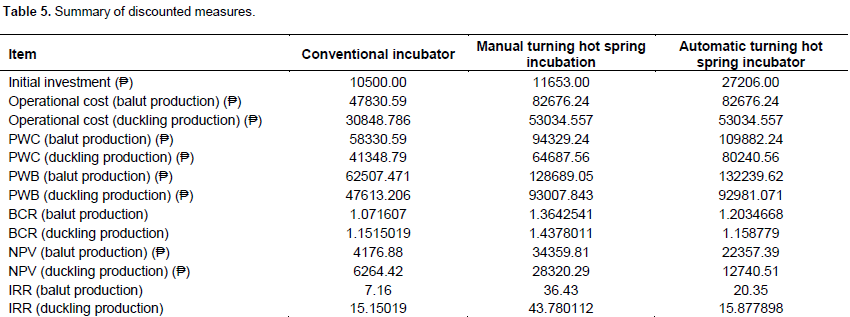

The discounted measure is the most reliable because it is a function of three components: (a) a risk free rate, (b) a general risk premium covering both equity risk and industry risk, and (c) a factor for company-specific risk (Larrabee and Voss, 2012). For feasibility of the discounted measures (benefit cost ratio and the internal rate return) used, the rate on agricultural loan was considered. The interest rate was 21%. All otherassumptions were similar to that of the undiscounted measures. The estimated life of the conventional electricity incubator and the hot spring incubator (manual turning and automatic turning) was five (5) years. No labor was taken into consideration, because the research focus on small scale farmers and all values in Table 5 are present value. For the benefit-cost ratio (BCR) of balut production, the conventional electricity incubator, manual and the automatic turning hot spring incubators were 1.07; 1.36 and 1.20, while the BCR for duckling production were 1.15; 1.44 and 1.16, respectively. The BCR showed that all the incubators are feasible since BRC≥1. The maximum BCR for balut and duckling production were 1.36 and 1.44, respectively, for the manual turning hot spring incubator for duck eggs.

For the net present value (NPV) of balut production, the conventional electricity incubator, manual and the automatic turning hot spring incubator were 4176.00; 34359.81 and ₱ 22357.39, while the NPV for duckling production were 6264.42; 28320.29 and ₱ 1240.51, respectively. The NPV revealed that all the incubator were economically feasible since NPV≥0. The maximum NPV for balut and duckling production were 34359.81 and ₱ 28320.29, respectively, for the manual turning hot spring incubator for duck eggs. For the internal rate of return (IRR) of balut production, the conventional electricity incubator, manual turning hot spring incubator and the automatic turning hot spring incubator were 7.16, 36.43 and 20.35, while the IRR for duckling production were 15.15, 43.78 and 15.88, respectively. The IRR is the most useful discounted measure for project worth. The maximum IRR for balut and duckling production were 36.43 and 43.78, respectively.

The low break-even point and payback period were 1950 balut and 0.751 year, respectively for balut production using the manual turning hot spring incubator. Based on the analysis of the undiscounted measures, the most feasible to invest in the development of a large scale hot spring incubator with manual turning for duckling production was shown. Using the discounted measures of economic analysis, the maximum benefit-cost ratio, maximum net present value and maximum IRR were 1.44; ₱ 34359.81 and 43.79, respectively using the manual turning hot spring incubator. The hot spring manual turning incubator can also be used on a small scale for hatching and replacement of ducks to sustain production without buying ducklings and it can also be used for balut production. The developed manual turning hot spring incubator with no temperature control device is highly recommended for low cost operations of duckling and balut producers. It can also be built on a large scale for commercial purposes in Los Baňos, Laguna, Republic of the Philippines. Based on the flow rate of hot spring, only 0.447 L/s was used and the total flow rate of the hot spring was more than 1 L/s by combining the flow rate of the three. On a full scale extraction of hot spring for incubation, the incubator can have the capacity of more than 4000 eggs per outlet which could result in the total capacity of 12000 eggs.

The authors have not declared any conflict of interests.

The authors thank the Ministry of Agriculture, Republic of Liberia; the Agricultural Sector Rehabilitation Program (ASRP) in Liberia for funding this research. They also extend their thanks to the University of the Philippines-Los Baňos (UPLB) and finally, the Central Agricultural Research Institute (CARI).

REFERENCES

|

Abbas T, Bazmi AA, Bhutto AW, Zahedi G (2014). Greener energy: Issues and challenges for Pakistan-geothermal energy prospective. Renew. Sustain. Energy Rev. 31:258-269.

Crossref

|

|

|

|

Atienza M, Rodriguez DPGM, Babilonia DR, Guimary M, Rebancos C (2015). Food safety study of duck eggs produced along Laguna Lake areas, Philippines. J. Nutr. Food Sci. S3:005.

|

|

|

|

|

Barbier E (2002). Geothermal energy technology and current status: an overview. Renew. Sustain. Energy Rev. 6(1):3-65.

Crossref

|

|

|

|

|

Bhutto AW, Bazmi AA, Zahedi G (2011). Greener energy: Issues and challenges for Pakistan-Biomass energy prospective. Renew. Sustain. Energy Rev. 15(6):3207-3219.

Crossref

|

|

|

|

|

Chang HS, De Castro N, Malabayabas ML, Dagaas C, Ranola Jr R, Lambio A (2006). Duck Marketing in the Philippines: Issues and Opportunities. Anim. Husb. Agric. J. 40:16-30.

|

|

|

|

|

Dagaas CT, Chang HSC (2004). The Philippine duck industry: issues and research needs (No. 12904).

|

|

|

|

|

Dickson MH, Fanelli M (2013). Geothermal energy: utilization and technology. Routledge. Hoboken, NJ: Taylor and Francis.

|

|

|

|

|

Fanchi JR (2005). Energy in the 21th Century. World Scientific Publishing Co. Pte. Ltd. 256p.

|

|

|

|

|

Fontaine JM, Dargnies C, Delalande A (2016). Developing Social Business Initiatives for Access to Energy, A Key Success Factor for Sustainability: The Awango Project. SPE International Conference and Exhibition on Health, Safety, Security, Environment and Social Responsibility. P 423.

Crossref

|

|

|

|

|

Jago-on KAB, Siringan FP, Balangue-Tarriela R, Taniguchi M, Reyes YK, Lloren Lloren R, Peňa MA, Bagalihog E (2017). Hot spring resort development in Laguna Province, Philippines: Challenges in water use regulation. J. Hydrol. Reg. Stud. 11:96-106.

Crossref

|

|

|

|

|

Larrabee DT, Voss JA (2012). Valuation techiniques- discounted cash flow, earings quality measures of value added and real options. Wiley 624p.

|

|

|

|

|

Magat M (2015). BaluT: FerTIlIZed duCk eGGs and TheIr role In FIlIPIno CulTure. Food Folklore Reader. P 122.

|

|

|

|

|

Miller TR, Levy DT (1998). The benefits and costs of brief alcohol interventions. Landover, Md: Pacific Institute for Research and Evaluation; 1998. Working paper.

|

|

|

|

|

Turvey R (1963). Present value versus internal rate of return- An essay in the theory of the third best. Econ. J. 73(289):93-98.

Crossref

|

|