ABSTRACT

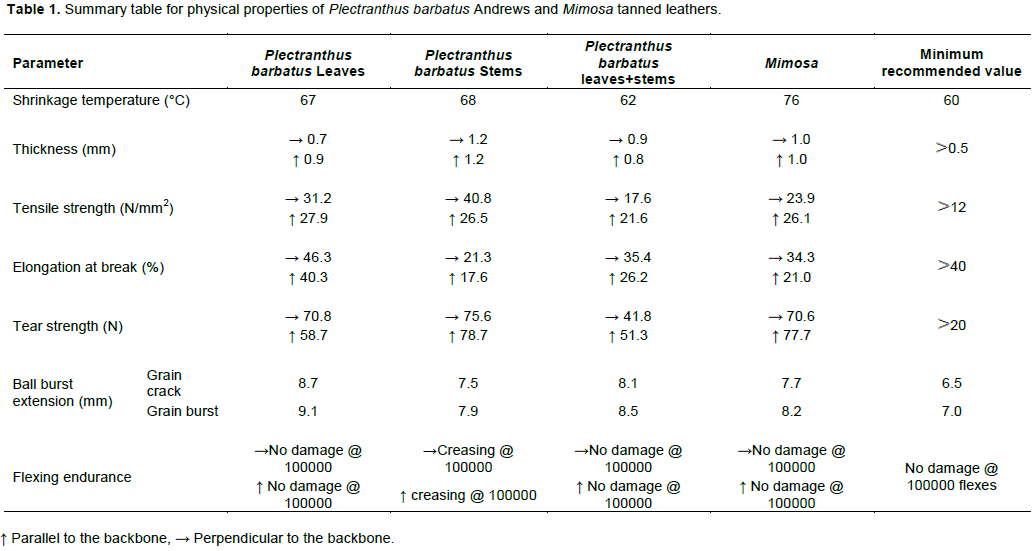

This study was designed to assess the potential use of Plectranthus barbatus Andrews, a plant growing locally in Kenya as a vegetable tanning agent. The aim was a deliberate attempt to adopt green chemistry and provide cheap locally available eco-friendly tanning materials. Anova statistical test (α<0.05) was used to compare the physical properties of leather tanned with three kinds of liquors made from the plant and the following mean values were recorded: Shrinkage temperature of 61.5 to 67.5°C; Grain crack range of 7.5 to 8.7 mm; Grain burst range of 7.9 to 9.1 mm; tear strength of 41.8 to 78.2 N with percentage (%) elongation of 68.4 to 75.9%; tensile strength of 17.6 to 40.8 N/mm2 with % elongation of 15.9 to 42.2% and thickness of 0.7 to 1.2 mm. The study concluded that P. barbatus Andrews leaves have adequate tannin content of hydrolysable type required for tanning. Furthermore, the brown colour of the leather produced is unlikely to undergo saddening as usually observed in Mimosa because of relative stability of hydrolysable tannins to light.

Key words: Shrinkage temperature, distension, pelts, tannins, vegetable tanning, pyrogallol.

Conversion of hides and skins into leather involves modification and partial purification of collagen in the beamhouse followed by stabilization through introduction of tanning agents that cross-link its fibres to prevent decomposition and confer versatility. Although chrome tanning is popular in industrial production of leather, the residual chrome in tannery waste pollutes the environment with oxidation of chrome (iii) to carcinogenic chrome (vi) in leather articles (Graf, 2001).

Consequently, there is growing concern on human health and environmental risk posed by accumulation of severely high levels of toxic chrome in underground and surface water due to seepage and direct flow from tannery effluent (Hossain and Bhuiyan, 2010). Vegetable tanning has been identified as an alternative to chrome (Covington, 2011) which has move towards green tanning chemistry and eco-labeling. However, vegetable tanning is not as widely used as chrome in Kenya due to the high cost of Mimosa, which is the only available vegetable tanning agent for commercial tanning. There is also limited knowledge and information about indigenous plants that may have potential use as vegetable tanning agents in Kenya.

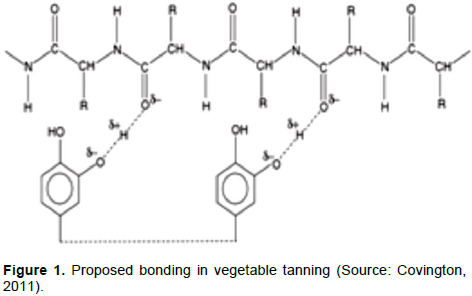

Plectranthus barbatus Andrews belongs to the largest family Lamiaceae of the order Lamiales, which has herbs and shrubs with distinct four sided stems and blue raceme inflorescence (Mariya et al., 2013). The entire plant is aromatic with leaves and roots having different odours (Lukhoba et al., 2006). It is an indigenous plant growing in many parts of Kenya mainly used for herbal medicine and establishment of land demarcations. The plant was identified as a potential candidate for study due to its resistance to fire, a salient characteristic of plants that are rich in tannins (Katie et al., 2006). The tannin content of P. barbatus Andrews crude extracts were determined using the hide powder method which was found to be 20 and 8% in leaves and stems respectively (D. Obiero, University of Nairobi, Kenya, unpublished results). Plants have since prehistoric times been utilized in organic tanning molecules and the pelt collagen react to form leather. The leather produced has improved physical characteristics performance for instance tear and tensile strength, shrinkage temperature, distension, flexing endurance, feel, handle and opacity (Covington, 2011). These alterations are thought to occur when polyhydroxyl groups in tannin molecules form bonds with the functional groups on the polypeptide chain especially –COOH (Covington, 2011). The proposed bonding in vegetable tanning is either through hydrogen bonds, ionic bonds or covalent bonds (Covington, 2011). Separately, Haslam (2007) contemplated of preferential binding in gap region of the quarter stagger structure of skin collagen. Figure 1 illustrates theoretical cross-linking of vegetable tannins with polypeptide chain.

Generally, leather tests are divided into three main classes: physical/ mechanical tests of strength, moisture related tests and chemical analysis (Thorstensen, 1993). These properties have variations depending on the various factors but most importantly the type of tanning agent. In contemporary leather science shrinkage temperature has been used to measure tanning activity although, some studies argue that the shrinking and tanning reactions are independent (Covington, 2011).

Furthermore, in vegetable tanning, shrinkage tempe-rature is not of commercial importance (Thorstensen, 1993), rather the suitability and performance in intended use. For instance, pyrogallol tanning is coupled with deposition of a pale-colored sediment called 'bloom' (ellagic acid) which when deposited in the leather contributes to its colour and improves its solidarity, wearing properties and resistance to water (Covington, 2011). Leather by nature is an inconsistent material (Thorstensen, 1993) hence independent leather testing and analysis becomes important before use use (Sterlacci, 2010) especially when a new tanning material is proposed.

Duplicates of bated goat pelts were tanned in separate drums for each category of liquor prepared by dissolving ground dried leaves, stems and a mixture of leaves and stems of Plectranthus barbatus Andrews sourced from Nyamira County in Kenya. Control pair of pelts was tanned with Mimosa for purposes of comparison. All tannery chemicals and reagents were of recommended standards and high quality. Standardized equipment and machinery were used in the measurement of leather physical properties.

Ground P. barbatus Andrews leaves, stems combined with leaves, stems and Mimosa were dissolved in warm water in separate containers to yield 5% extracts before 150% floats of resultant liquors in regards to the weight of the bated pelts that were put into drums. The pairs of bated pelts were then immersed in the respective floats and drums run at an initial uniform speed of 8 rev/min for 6 h. Tanning progress was monitored by checking change of liquor colour and penetration through the pelt cross-section3% addition of the extracts was made carefully then run for 1 h before the pelts were left to stand overnight, completely immersed in the liquor.

Penetration of the extracts was inspected by cutting a small piece in the neck region of the pelt and colour uniformity through the pelt cross-section was used to establish completion of tanning. Additions of subsequent reduced percentages of extract concentrations were made and drums run until each tannage was complete and thereafter fixation was done with 1% formic acid. All the P. barbatus Andrews tanned leathers were further re-tanned in the same respective 5% extracts liquors after they had been horsed up for one day and later hang dried in the air for one day in order to improve colour, handle and weight. The dried leathers were then fatliquored with 4% vegetable oil followed by toggle drying.

Each processed leather sample was labeled, then sampling and measurement of the following physical parameters was done according to the official methods of International Union of Leather Technologists and Chemists Societies (IULTCS) (2001): Shrinkage temperature was measured on SATRA STD 114 (IUP/16), flexing endurance on Bally Flexometer Model 2184 (IUP/20), thickness (IUP/4), tear strength and tensile strength on Instron 1011(IUP/8; IUP/6) and distension test on Lastometer STD 104- SATRA test equipment (IUP/9). Data analysis was done using ANOVA statistical test (α<0.05).

P. barbatus Andrews leaves, stems and a com-bination of leaves and stems tannages produced brown, black and brown coloured leathers respectively. All other results are recorded in Table 1. The thickness of the leathers was a significantly different (p=0.0) among the four types of leathers with Mimosa tanned leathers having the highest mean value of 1.1 mm followed by P. barbatus Andrews stem extract tanned leathers at 1.0 mm while leaves extract tanned leather was the thinnest at 0.7 mm with an overall coefficient of variation of 38.6%. Earlier work has reported Acacia nilotica tanned leathers of West African dwarf goats and Sahelian goats with values above 0.98 and 0.87 mm respectively which were also reported for Lori goat breed of Iran (Salehi et al., 2013).

The mean shrinkage temperature of raw goat skins used in tanning was 55°C therefore P. barbatus Andrews leaves tannage recorded a rise in 12°C and stems tannage managed an increase in 13°C which was the highest. The mixture of leaves and stems showed a minimum elevation of 7°C in regard to this parameter and this was thought to have been due to unfavorable interactions between soluble compounds in the two components. Comparatively natural valonia tanned kidskins leather reported a mean shrinkage temperature of 65.66°C (Afsar and Sekeroglu, 2008) and hence the observations made in this study were not inconsistent with earlier studies on hydrolysable tanning materials. Other previous studies show that shrinkage temperature of leather tanned with condensed tannins (Mimosa) is between 80 to 85°C and for hydrolysable tannins (sumac) the shrinkage temperature is <80°C (Covington, 2011). Divi-divi and myrobalan tannages (hydrolysable) both have a shrinkage temperature of 68°C and quebracho and wattle tannages (condensed) produce leather with a shrinkage temperatures of 76 and 78°C respectively (Covington, 2011).

However, it is assumed that the shrinking reaction is independent of the stabilizing effect because the enthalpy of denaturation is independent of stabilizing chemistry (Covington et al., 1989). Hydrothermal stability depends on the chemistry of bonding with hydrogen bonding conferring only moderate rise in shrinkage temperature; this may be assumed to be the case with P. barbatus Andrews tannage. No similar work has been done with P. barbatus Andrews in previous studies and consequently the comparison is only strictly based on materials with similar type of tannins (hydrolysable) though not exactly the same.

The higher the grain bursting height, the greater the softness achieved in the leather (Jianzhong et al., 2003) and results of tested leathers indicated good softness with no significant difference (p=0.18) among the three forms of P. barbatus Andrews tanned leathers. Leaves tannage gave the best outcome of 9.1 mm and comparatively De-Britol et al. (2002) also recorded that, the minimum recommended bursting height of good leather is 7.0 mm.

Leathers tanned with P. barbatus Andrews stems had the highest tear strength of 80.0 N that was 0.5 N higher than the strength tested in Mimosa tanned leather. Leaves and stem mixture tanned leather showed the lowest tear strength of 39.0 N whereas leather tanned with P. barbatus Andrews leaves liquor had a measured tear strength value of 47.3 N. There was a significant difference (p=0.0) between the tear strength means of the four tannages however, the difference is between P. barbatus Andrews leaves combined with stems and Mimosa, combined leaves and stems and stems (p=0.0), stems and Mimosa (p=0.0), leaves and Mimosa (p=0.0) and leaves compared with stems (p=0.0) tannages. There was no significant difference (p=0.12) between P. barbatus Andrews leaves and combined leaves and stem tanned leathers. Related studies show that Acacia nilotica tanned leathers have tear strength of 40 N, semi-chrome 47 N and Bureau of Indian Standards (BIS) which gives a value of 30 N (Musa and Gasmelseed, 2013).

No significant difference (p=0.6) was seen among P. barbatus Andrews tannages that is; leaves, leaves combined with stems and stems alone in regard to tensile strength. Stem tannage showed the highest tensile strength of 48.5 N/mm2 while leaves tannage recorded the lowest value of 43.2 N/mm2. When compared with Mimosa which had a mean tensile strength of 25.0 N/mm2 there was no significant difference (p=0.2) among the four tannages. Previous research on A. nilotica tanned goat skins recorded a tensile strength of 23.5 N/mm2 and BIS sets the value at 19.6N/mm2 (Musa and Gasmelseed, 2013).

The percentage elongation at break values, among the P. barbatus Andrews tanned leathers revealed no significant difference (p=0.5) with a mean of 22% and a maximum value of 50% posted by both P. barbatus Andrews leaves and leaves combined with stems tannages. When this property was compared with Mimosa which had a highest value of 53% and a mean % elongation value of 28%; which was the highest among the four types of leathers, the statistical analysis showed no significant difference (p=0.5) among them. Comparatively leathers produced by tanning goat skins with Acacia nilotica pods by Sudan rural tanners had a percentage elongation value of 41% and semi-chrome giving a value of 58% with BIS range between 40 to 65% (Musa and Gasmelseed, 2013).

The leather tanned with P. barbatus Andrews stems was brittle but when it was re-tanned with additional 20% offer, it showed improvement in the flexing endurance since it completed the 100,000 dry flexes with minimum creasing and change in colour. All other categories had good feel and recommended flexibility but it is important also to remember that several factors such as breed, age at slaughter, nutrition and environment also influence the physical properties of leather (Yusuff et al., 2013). For this reason it is therefore expected that these properties will vary considering studies done in different parts of the world. Results of flexing endurance of Acacia nilotica tanned goats skins in Nigeria from three breeds: West African dwarf, Sahelian and Sokoto red goats showed that 5.83% of the samples subjected to flexometer test showed emergence of cracks however there was no significant difference (p>0.05) among them (Yusuff et al., 2013).

The colours produced by the three P. barbatus Andrews tannages were notably different with leaves tannage and the mixture of leaves and stems yielding brown leathers while the stems tannage gave rise to black leathers. Undyed vegetable tanned leather will show varying shades of brown, yellowish brown or reddish brown (Mongkholrattanasit et al., 2011). Catechols produce red, pink and dark brown leathers while pyrogallols produce paler tans (Covington, 2011). The brown colour of the leather produced is unlikely to suffer saddening as usually observed in Mimosa because of relative stability of hydrolysable tannins to light (Covington, 2011).

This study concluded that P. barbatus Andrews leaves have adequate tannin content required for tanning and this plant can produce leather with quality comparable with conventional Mimosa tanned leathers. It was recommended that leaf extracts from P. barbatus Andrews can be used for tanning light leathers and also re-tanning. Leaves sourced from Nyamira County in Kenya can be used in rural tanning however, commercial production of the plant should be, encouraged through intercropping especially in small holder farming communities in order to boost their income.

The authors have not declared any conflict of interests.

This research work was funded by the National Commission for Science, Technology and Innovation (NACOSTI).

REFERENCES

|

Afsar A, Sekeroglu O (2008). An investigation about the effect of oxazolidine on modified valonia extract tanning. African Journal of Biotechnology 7(20):3737-3742.

|

|

|

|

Covington AD (2011) Tanning Chemistry. The Science of Leather. The Royal Society of Chemistry, Cambridge UK. pp. 281-314.

|

|

|

|

|

Covington AD, Hancock R A, Ioannidis I A (1989). Study of neem bark tannins for the leather industry. Journal of the Society of Leather Technologists and Chemists 73(1):1.

|

|

|

|

|

De-Britol ALF, Prasad S, Muniz ACS (2002). Re-tanning of goat skin using aldehyde after utilization of trivalent chromium salt. Journal of The American Leather Chemists Association 97:1-18.

|

|

|

|

|

Graf D (2001). Formation of Cr (vi) traces in chrome tanned leather: Causes, prevention and latest findings. Journal Of The American Leather Chemists Association 96(5):169-179.

|

|

|

|

|

Haslam E (2007). The details on the mechanisms and structure-reactivity relationship of vegetable tannins. Journal of the Society of Leather Technologists and Chemists 81(2):45.

|

|

|

|

|

Hossain MA, Bhuiyan (2010). Investigation of possible sources of heavy metal contamination in lagoon and canal water in the tannery industrial area in Dhaka, Bangladesh. Environmental Monitoring and Assessment 175 (1-4):633-649.

Crossref

|

|

|

|

|

IULTCS (2001). The IULTCS official methods of analysis for leather. The Society of Leather Chemists and Technologists.

|

|

|

|

|

Jianzhong Ma, Lingyun Liu, Chunhua Xu (2003). Protein re-tanning and filling agent from vinyl monomer graft modification of chrome shavings hydrolysate. Journal of the Society of Leather Technologists and Chemists 88(1):1-5.

|

|

|

|

|

Katie EF, Thorington RW, Katherine E (2006). Squirrels the animal answer guide. Baltimore: Johns Hopkins University Press. P.91.

|

|

|

|

|

Lukhoba CW, Simmonds MS, Paton AJ (2006). Plectranthus: A review of ethnobotanical uses. Journal of Ethnopharmacology103:1-24.

Crossref

|

|

|

|

|

Mariya P, Radha A, Suresh KD (2013). On the high value medicinal plant, Coleus forskohlii Briq. Hygeia Journal for Drugs and Medicines 5(1):69-78.

|

|

|

|

|

Mongkholrattanasit R, Krystufek J, Wiener J, Studnickova J (2011). Natural dye from Eucalyptus leaves and application for wool fabric dyeing by using padding technique. INTECH Open Access Publisher.

Crossref

|

|

|

|

|

Musa AE, Gasmelseed GA (2013). Application of Acacia nilotica ssp. nilotica (powder) as alternative vegetable re-tanning material. Forest Products Journal 3(2):112-117.

|

|

|

|

|

Salehi M, Lavvaf A, Farahvash T (2013). Skin quality and physical properties of leather based on sex, age and body parts of goats reared on Sub-humid hill country. Iran. Journal of Applied Animal Research3(4):853-857.

|

|

|

|

|

Sterlacci F (2010). Leather Fashion Design. Laurence King Publishing Ltd London. pp. 160-166.

|

|

|

|

|

Thorstensen TC (1993). Practical Leather Technology 4th Edition: Krieger Publishing Company. pp. 147-171,318-324.

|

|

|

|

|

Yusuff AT, Adesiyun AA, Fayeye TR (2013). Effect of tanning on the physical properties of leathers from three Nigerian goat breeds. International Journal of Phytofuels and Allied Sciences2(1):125-134.

|

|