ABSTRACT

This work aimed to investigate the impact of Instant Controlled Pressure Drop (DIC) treatment on the technological quality of Gluten-Free Bread (GFB) based on Rice-Field bean Formula (RFF). Two DIC factors were used as independent parameters of a Design of Experiments (DoE); X1: DIC temperature ranged from 100 to 165°C which was rigorously correlated with the dry saturated steam pressure ranged between 0.1 and 0.7 MPa, and X2: the processing time ranged from 20 to 60 s. The main response (Y) was the specific Volume (Vsp) of the GFB. The statistical analysis was performed using the Response Surface Methodology (MSR) to study and optimize the DIC treatment effect on technological quality (Vsp) of the GFB. The breads crumb was characterized by image analysis. The GFB optimum from RFF was obtained with DIC steam pressure of 0.3 MPa (temperature of 132.5°C) for a short treatment time of 20 s. It provided the highest Vsp of 2.7 ± 0.04 cm3/g with an improvement of 10.20% than the GFB control and a great total number of alveoli. Hence, DIC treatment was an effective improvement mean of technological quality of GFB based on RFF for celiac patients.

Key words: Instant controlled pressure drop (DIC), rice-field bean formula, gluten-free bread, design of experiments (DoE), specific volume, crumb structure.

Celiac disease (CD) is considered as one of the most widespread gastro-intestinal diseases. It is a stateof

autoimmune response to gluten proteins in a genetically predisposed subject, characterized by nutriment malabsorption caused by the atrophy of intestinal mucosa (Lionetti and Catassi, 2011; Lebwohl et al., 2018). It touches approximately 1% of the world’s population with a great variation between countries (Makharia et al., 2011; Do Nascimento et al., 2017). Currently, the only treatment for CD is exclusively dietetic: a lifetime strict gluten-free diet, which entails removing any source of gluten containing in wheat, barley and rye and to substitute them by other gluten-free cereals such as rice and corn (O’Shea et al., 2014).

Bread is the basic consumed food in the world. However, its manufacture based on gluten-free ingredients remains difficult with a lower quality than the conventional wheat bread (Benatallah et al., 2012), due to the absence of the gluten, which is a great challenge for cereal researchers on gluten-free bread making (Masure et al., 2016). Many studies carried out for answering this problem were based on substituting the gluten by adding specific ingredients and additives like starches (Bourekoua et al., 2016; Bourekoua et al., 2018), proteins (Phongthai et al., 2016), enzymes (Mohammadi et al., 2015; Calle et al., 2020) and hydrocolloids (Benatallah et al., 2012).

Furthermore, the National Council of Food (CNA) (2009) of France highlighted the interest of the use of physical treatments in food industry in which these treatments could modify the chemical, functional, molecular, and structural properties of the raw materials used in the production of various foods. Among these physical treatments, the Instant Controlled Pressure Drop (French: Détente Instantanée Contrôlée- DIC) technology, which was defined in 1988, as a high temperature-short time stage usually carried out by establishing high-pressure dry saturated stream-high temperature (usually between 0.1-0.7 MPa relating with 100-165°C) during 5-60 s. This ends by an instant pressure-drop towards a vacuum of about 0.005 MPa and an instant cooling, at a rate ΔP/Δt higher than 0.5 MPa s-1 (Allaf and Vidal, 1989).

This thermo-mechanical treatment method has been used in many industrial applications such as drying and texturing of plants (Louka and Allaf, 2002; Albitar et al., 2011; Nguyen, 2015), microbiological decontamination (Setyopratomo et al., 2009), extraction volatile compounds and essential oils (Kristiawan et al., 2004; Besombes et al., 2010), and steam treatment of cereals (Habba and Allaf, 1997; Duong et al., 2008; Pilatowski et al., 2010).

However, the effect of Instant Controlled Pressure Drop (DIC) treatment on the quality of GFB has never been previously studied. Therefore, this study aimed to investigate and optimize the effect of DIC treatment on the technological quality (specific volume) of GFB based on RFF, with the objective of improving the situation of celiac patients.

Raw materials

White long rice grain (Oryza sativa) from Basmati variety obtained from India and field bean seeds (Vicia faba minor) obtained from an Egyptian Company (Elamir Company, Egypt) were used in our study. Rice and field bean seeds were ground by a laboratory mill (Moulinex, France); thereafter, the flours obtained were sieved manually with 200-μm seive. The Gluten-Free Formula (GFF) used was based on the mixture of rice and field bean flour with a ratio 2/1 (w/w). The soft wheat flour was used for the control bread. Additional ingredients were used such as bakery freeze-dried yeast, Saccharomyces cerevisiae (S.I. Lesaffre, France) and salt (ENASel, Algeria). All these raw materials were purchased from an Algerian local market.

Chemical composition of flours

Chemical composition of rice and field bean flours was determined following the ISO methods for moisture (ISO 712: 2009) and ash content (ISO 2171: 2010), and the AACC methods (1995) for protein (AACC 46-10) and lipid content (AACC 30-10) in three replications. Total carbohydrates content was evaluated by subtracting the total percentage of the other components from one hundred.

Instant controlled pressure drop (DIC) treatment of gluten-free formula

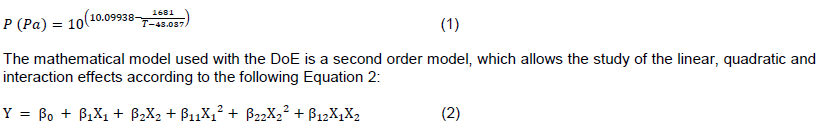

In the present study, DIC equipment used for the GFF treatment was a laboratory scale DIC unit (manufactured and provided by ABCAR-DIC Process, La Rochelle, France) (Figure 1). It consists of 11-L processing vessel with heating jacket, where samples are set and treated, a 1.6 m3-vacuum tank with cooling water jacket, a water ring vacuum pump, a steam generator with a thermally isolated storage tank and a specific condensed steam trap; a large-section pneumatic valve that assures an “instant” connection between the vacuum tank and the processing vessel that can be opened in less than 40 ms (Allaf, 2013).

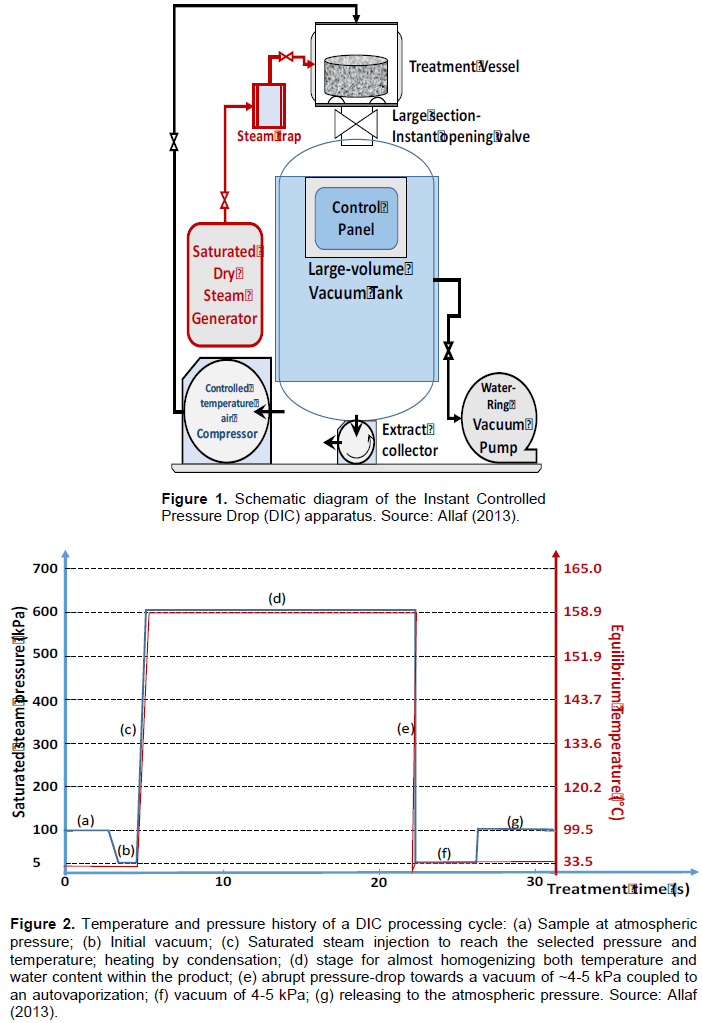

DIC treatment of the different GFF samples, starts by placing 180 g of sample within a bag of coffee-type filter and positioning it in the treatment vessel at atmospheric pressure (Figure 2-phase a). After closing it, an initial vacuum stage (about 5 kPa =0.005 MPa) was established (Figure 2-phase b) in order to remove the air presented in the vessel and, thus to assure close contact between the surface of the sample and the saturated dry steam to be injected just after (Figure 2-phase c). As demonstrated by Allaf and Allaf (2014), the use of dry saturated steam allows a subsequent hugely-fast heating by condensation. In our case, dry saturated steam pressure ranged between 0.10 and 0.70 MPa according to a specific design of experiments (DoE) we adopted based on the know-how of the research team, the literature, and a preliminary series of trials. This allowed the treatment temperature to be between 100 and 165°C. This stage (Figure 2-phase d) of 20 to 60 s ends by an abrupt pressure-drop towards a vacuum (5 kPa = 0.005 MPa) (Figure 2-phase e) obtained by opening the pneumatic large-section instant valve. Finally, the atmospheric pressure was restored in the treatment vessel (Figure 2-phase g) and the sample was recovered.

Design of experiments (DoE)

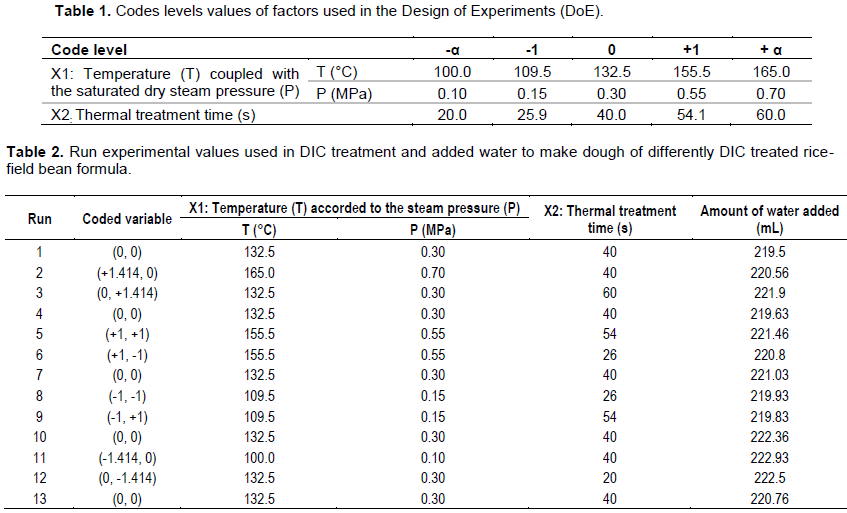

In order to study the effect of DIC operating parameters on the Vsp of GFB based on RFF, a specific DoE was carried out. It was a 5-level (-α, -1, 0, +1, +α) DoE with two factors; X1: DIC temperature (T) coupled with the dry saturated steam pressure (P) and X2: the thermal treatment time (t) (Table 1). In this case, DoE included 13 trials: 2n=22=4 factorial points (-1,-1), (-1,+1), (+1,-1) and (+1,+1); 2×n=2×2=4 star-points (-α,0), (0,-α), (0,+α), and (+α,0); and 5 replicates for the center-point (0,0) were added. DIC treatment experiments were carried out in random using the operating conditions done in Table 2. The saturated dry steam pressure (expressed in Pa) applied in the current DIC range was accorded to the temperature level (T) (expressed in K) following the Equation 1:

Optimization

The DIC treatment optimization consisted of defining the highest value of the studied response (Vsp). For that, the response surface of the Vsp of GFB from RFF was represented versus DIC factors (X1 and X2) of the couple (temperature-time). To confirm the optimized result computed by the MSR, a second experiment series was performed including selected couples of temperature-time inside and outside the optimal delimited zone, in which the Vsp of the obtained GFB was determined.

Bread making process

In bread making test, the GFF used was based on rice and field bean flour with a ratio 2/1 (w/w) aimed to obtain a better nutritional balance of essential amino-acids (FAO, 1982; Benatallah et al., 2012).

For the 13 samples of treated DIC rice-field bean formula and the untreated formula, the amount of water added to each sample depended on its moisture content and it was calculated so that all the dough samples had the same final water content (70 g of water for 100 g of dough) (Table 2). So, preliminary tests allowed defining the hydration levels of manufacturing GFB as ranged between 219.5 and 222.93 mL of water for 100 g of rice/field bean flour. As for the control dough with soft wheat, preliminary tests based on obtaining the best Vsp of bread helped to retain an optimal hydration level of 61 mL of water for 100 g of wheat flour.

The bread recipe used consisted of 66.66 g of rice flour, 33.33 g of field bean flour, 2 g of salt, 2 g of instant freeze-dried yeast (Saccharomyces cerevisiae) and the amount of water suitable for each sample (Table 2). These ingredients were mixed for 15 min twice, with a 5-min break, in a kneader (HEIDOLPH RZR 2020, Germany) at 25°C. The resulting dough was divided in lumps (45 g) and put into a silicon mold (9×4.7×3 cm3), and then proofed at 37°C in wet atmosphere for 45 min in a fermentation cabinet (MEMMERT, France). The baking tests were performed in an electric oven (SAMSUNG, Germany) at 230°C in wet atmosphere for 55 min for GFB based on DIC-treated rice-field bean formula, 22 min for the control GFB and 15 min for the control wheat bread.

Gluten-free bread quality evaluation

After 60 min post-baking, GFB characterization was carried out by the determination of Vsp and the image analysis of bread crumb structure.¶

Volume was determined by the rapeseed displacement method according to the AACC Approved Method 10.05 (AACC, 2000). Vsp of bread expressed in "cm3/g" was calculated by dividing its volume (V) by its mass (M).

According to Gonzales-Barron and Butler (2006), image analysis of bread crumb was performed using Image J software (version 1.43, National Institutes of Health, USA). Slices of bread (1 cm thick) were scanned using a flatbed scanner (Epson stylus SX 105) with a resolution of 300 dots per inch. The parameters recorded were the number of cells, the average surface and cells circularity (shape).

Statistical analysis

Statistical analysis of the design of experiments (DoE) was performed with MINITAB 17 software (Minitab Inc., PA State College, USA) and the response surface was traced using STATISTICA version 10 software (Stat Soft, France). The K-means test was applied to classify (regroup) the different types of breads. A coefficient of determination (R2) was computed and the model adequacy was tested by separating the residual sum of squares into pure error and lack-of-fit. The significance level was set at 0.05.

Chemical composition of raw materials

The chemical composition results of rice and field bean flour used, expressed in percentage (based on dry basis), are given in Table 3. Rice flour was characterized by high carbohydrates (92.71%), lower protein (6.37%), fat (0.33%) and ash (1.37%) contents compared to field bean flour. The calculation of GFF composition based on rice and field bean flour with a ratio 2/1 indicated improvement in protein (14.05%), fat (0.88%), and ash (1.45%) contents due to the incorportion of field bean flour. The results obtained are in agreement with those reported for GFB made with rice/field bean flour with 2/1 (w/w) by Benatallah et al. (2012) and Bourekoua et al. (2016). Thus, the incorporation of legumes flours in gluten-free products enhances their nutritional quality (Lamacchia et al., 2014).

Model fitting

According to Goupy (2013) and Granato and de Araújo Calado (2014), the calculation of R2 coefficient is used to measure the DoE empirical model quality and the lower lack-of-fit indicated the adequacy of the model. The statistical analysis of the effect of DIC operating parameters (X1: the steam temperature coupled with the pressure, and X2: the thermal treatment time) on the Vsp (Y) of GFB indicated that the fitting model was adequate due to the reasonable value of R2 (0.73) and a non-significant lack-of-fit test (0.55).

Effect of DIC treatment on specific volume of gluten-free breads

The Vsp is one of the most important visual characteristics of bread, strongly influencing consumer choice, and it is the key-parameter for the bread quality evaluation (Hager and Arendt, 2013). The parameters of the statistical empirical model of the Vsp of GFB versus DIC factors are summarized in Table 4. It was observed that only the linear effect of DIC processing time X2 was significant with the value 0.033, based on the p value relative to 0.050 (p Ë‚ 0.05), whereas, the other terms were not significant (p > 0.05).

The effect of DIC operating parameters X1 and X2 on Vsp of GFB based on RFF is shown as response surface in Figure 3. It shows that the Vsp values varied from 1.2 to 2.8 cm3/g. Moreover, the highest Vsp was lower than that of the wheat bread control (3.03 ± 0.10 cm3/g), but it was higher than that of the GFB control from untreated formula (2.45 ± 0.04 cm3/g). The highest values of the Vsp were recorded for a wide range of temperature and steam pressure, coupled with a short treatment time, also for low temperature and steam pressure, and a long treatment time.

Optimization results

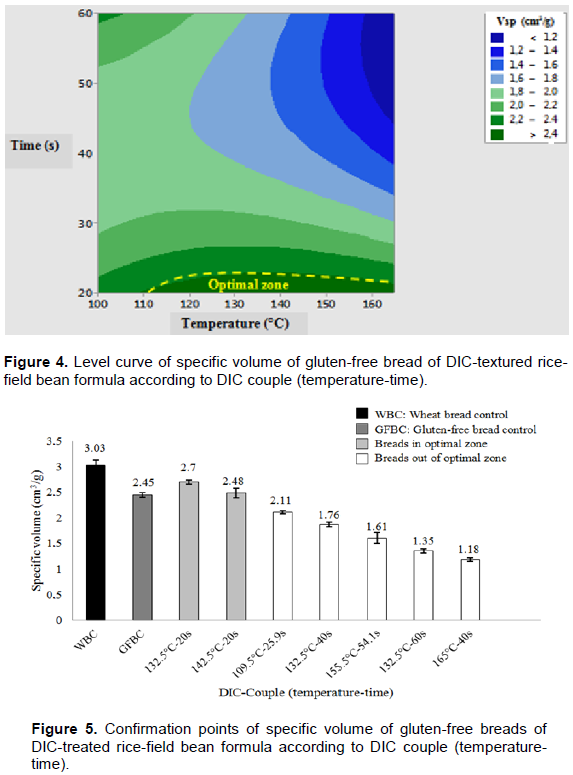

The level curve of the Vsp of GFB of DIC-treated rice-field bean formula according to couple (temperature-time) is illustrated in Figure 4. It shows that the highest Vsp values of GFB situated in the optimal zone, in which the Vsp values were higher than 2.4 cm3/g, include temperature that ranged from 110 to 165°C, steam pressure from 0.15 to 0.7 MPa, and low treatment time from 20 to 22 s.

Figure 5 represents the confirmation points selected inside and outside the optimal delimited zone of the Vsp of GFB based on DIC-treated rice-field bean formula. All the GFB presented lower Vsp than that of the wheat control bread (3.03 ± 0.10 cm3/g). Obviously, this is due to the absence of structural protein "gluten" in the raw material used in our study (Gallagher et al., 2004). Kawamura-Konishi et al. (2013) demonstrated the inability of rice proteins to form a three-dimensional viscoelastic network similar to that of wheat gluten, which results in low gas retention thus giving bread with low Vsp.

The k-mean classification indicates that the GFB obtained from the treated DIC-rice-field bean formula at 132.5°C (steam pressure of 0.3 MPa) for 20 s giving the highest Vsp of 2.7 ± 0.04 cm3/g would belong in the same class of wheat bread control. In addition, ¶this GFB showed an improvement of Vsp with a gain of 10.20% compared to the GFB control (2.45 ± 0.04 cm3/g). Therefore, it is considered as the optimum GFB of our present study. On the other hand, the GFB of DIC-treated rice-field bean formula at 142.5°C/0.39 MPa for 20 s gave a Vsp of 2.48 ± 0.09 cm3/g. This increase in Vsp of GFB of DIC-treated rice-field bean formula with these conditions compared to the GFB control, would probably be explained by the effect of DIC treatment on the properties of rice flour, which was the basic ingredient used in our GFF. According to Habba and Allaf (1997), Duong et al. (2008), and Pilatowski et al. (2010), the DIC treatment improved and controlled the rice quality compared to the untreated rice sample. Therefore, the Vsp improvement of GFB of DIC-treated rice-field bean formula could be explained by the DIC impacts in terms of texturing, expanding, and instant cooling. Indeed, the instant pressure-drop towards a vacuum causes an abrupt water autovaporization of the treated sample, inducing a modification of its structure as well as a significant cooling. In addition, Delgado-Rosas et al. (2006) showed that the DIC treatment applied to a maltodextrin powder effectively generates a porous structure with alveoli in the treated sample compared to the untreated one.

According to Prameswari et al. (2018), there is a relationship between the amount of water added during bread making procedure and the ability of flour to absorb water; consequently, the characteristics of bread were affected. Therefore, in our present study, the increase in Vsp of GFB optimum compared to the GFB control could be related to the amount of water added during dough preparation, in which the DIC-treated rice-field bean formula required higher water quantity. Our results are corroborated by those of Setyopratomo et al. (2009), who found that the water holding capacity of DIC-treated cassava flour was greater than that of untreated flour. They explain their results by the microstructure change of the treated sample, as the total pore volume and the specific surface. Therefore, the higher amount of water added had a positive effect on the Vsp of GFB based on DIC-treated Rice-Field bean Formula.

On the other hand, the structure of rice flour starch can be affected and modified by the DIC treatment as reported by Onyango (2016), for which this physical treatment (DIC) is one of the methods used to synthesize the physically modified starch. In addition, Onyango (2016) indicated that the damaged starch content of physically treated flours was higher than that of untreated flours, and therefore their water absorption capacity increased, which could be the reason of the Vsp improvement of the GFB optimum.

Also, it should be noted that the field bean flour incorporated in our GFF has improved the protein content (14.05%) than that of rice flour (6.37%) as previously indicated. According to Verni et al. (2019), field bean flour is characterized by a high protein content (26-39%) of good quality, and its mixture with cereal proteins allows a good balanced amino acid composition. Therefore, we can explain the Vsp improvement of GFB by the positive effect of DIC treatment on protein structure and properties of field bean flour compared to that of untreated formula.

Concerning the points selected outside the optimal delimited zone, the Vsp values recorded are lower than the wheat control and also than the GFB control. They ranged from 1.18 ± 0.04 cm3/g to 2.11 ± 0.03 cm3/g for the couple temperature/pressure-time: 165°C/0.70 MPa - 40 s and 109.5°C/0.15 MPa - 25.9 s, respectively. Therefore, the increase in temperature (increase in steam pressure) and time of DIC treatment causes the decrease of Vsp of GFB of RFF. It is possible to observe that, for the same temperature (same steam pressure), the increase in treatment time causes the decrease of Vsp of GFB. For example, the Vsp was 1.76 ± 0.04 cm3/g for the conditions 132.5°C/0.3 MPa and 40 s, whereas for 60 s it became 1.35 ± 0.03 cm3/g. In addition, the decrease of Vsp is generated by the increase in temperature (increase in steam pressure) for the same treatment time. For instance, for a treatment time of 40 s and a temperature of 132.5°C/0.3 MPa, the Vsp was 1.76 ± 0.04 cm3/g, whereas at 165°C/0.7 MPa, it decreases to 1.18 ± 0.03 cm3/g. These decrease in Vsp values could be explained by the intense negative effect of severe DIC conditions treatment (temperature/pressure-time) applied on the GFF of rice and field bean flour.

Structural characteristics of bread crumb

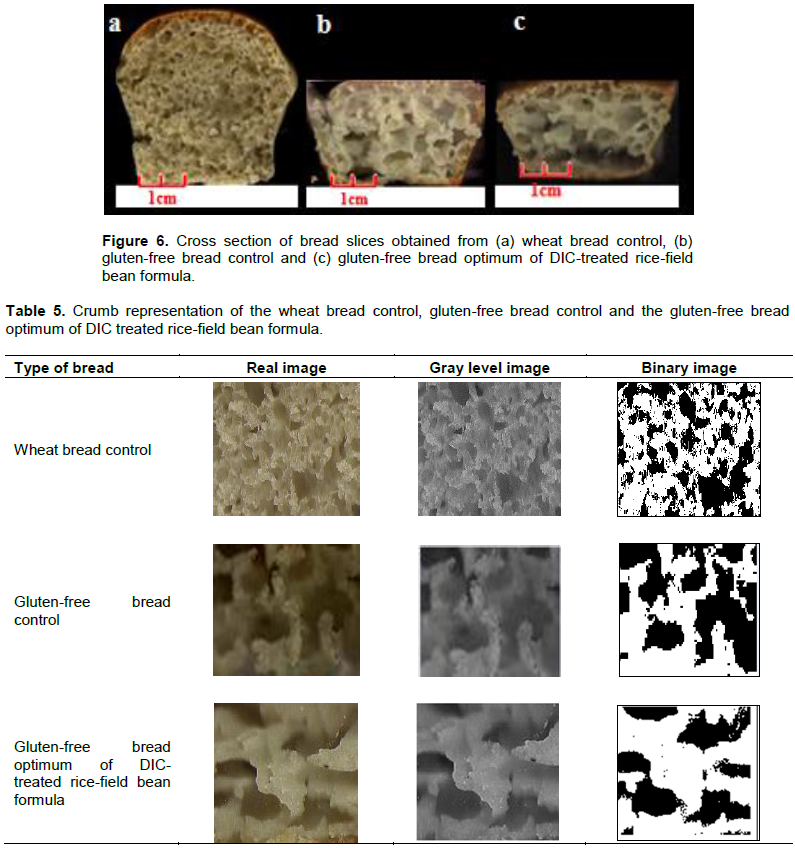

The crumb appearance of the GFB optimum of DIC-treated rice-field bean formula compared to wheat bread control and GFB control is shown in Figure 6. Our GFB optimum has a well-developed crumb and alveolar structure including a majority of large alveoli close to that of GFB control, in opposite, the wheat bread control presents a homogeneous alveolar distribution of small size.

Image analysis results of breads crumb revealed that the alveoli total number of GFB optimum of DIC treated rice-field bean formula (28 alveoli) was greater than that of GFB control (14 alveoli), but it remains inferior than the wheat control bread (110 alveoli). Concerning the average size, our breads presented the following values, 0.81, 0.19, and 0.096 for GFB optimum, GFB control and wheat bread control, respectively. In this case, the cells average size of GFB optimum was higher than that of the GFB control and the wheat bread control. Therefore, the DIC treatment of our GFF based on RFF facilitated the air bubbles creation and also favored their development during fermentation. This might be due to the water absorption capacity of treated formula during dough preparation as already mentioned above, as well as the sudden drop of pressure toward vacuum and the rapid autovaporisation of moisture sample during DIC treatment, which could modify the texture and the functional behavior of the material. Indeed, those breads have all a circular alveoli shape, with the values close to 1. Consequently, the DIC treatment did not affect the roundness values of the GFB optimum than the GFB control. According to Table 5, the crumb alveoli of our GFB optimum and that of GFB control are more open compared to the wheat bread control.

Our study confirmed the considerable contribution of Instant Controlled Pressure Drop (DIC) treatment in the improvement of the technological quality of GFB based on RFF. After performing statistical validation of the obtained model, the effect of DIC operating parameters on the Vsp of GFB was analyzed. The optimization results obtained by the Response Surface Methodology showed the optimal zone including a wide range of temperature between 110 and 165°C corresponding to steam pressures of 0.15 and 0.7 MPa, respectively, and low treatment time ranging from 20 to 22 s. After bread making test, k-means classification indicated that the GFB obtained from DIC treated Rice-Field bean Formula at 132.5°C (steam pressure 0.3MPa) during 20 s is categorized in the same class of wheat bread control, and it is considered as the GFB optimum of DIC treated Rice-Field bean Formula, which gave the highest Vsp of 2.7 ± 0.04 cm3/g with a gain of 10.20% compared to the GFB control (2.45 ± 0.04 cm3/g). Based on the results of image analysis of bread crumb, the alveoli total number of our GFB optimum of RFF treated with DIC was greater than that of the GFB control. On the other hand, the field bean flour incorporation has improved the nutritional quality of our GFF used in bread making by increasing its protein content. This work carried out in the present study deserved to be completed by in-depth analyzes to have more comprehensive results.

The authors have not declared any conflict of interests.

The authors thank Professor Allaf Karim and Besombes Collete of ABCAR-DIC PROCESS SAS, Laboratory of Engineering Science for Environment, University of La Rochelle, France for providing a set of DIC equipment.

REFERENCES

|

American Association of Cereal Chemists (AACC) (1995). Approved methods of the American Association of Cereal Chemists. 9th ed. St. Paul, USA. AACC. Available at:

View

|

|

|

|

American Association of Cereal Chemists (AACC) (2000). Approved methods of the American Association of Cereal Chemists. 10th ed. St. Paul, U.S.A.: AACC. Available at:

View

|

|

|

|

|

Albitar N, Mounir S, Besombes C, Allaf K (2011). Improving the drying of onion using the instant controlled pressure drop technology. Journal of Drying Technology 29(9):993-1001.

Crossref

|

|

|

|

|

Allaf K, Vidal P (1989). Feasibility study of a new process of drying/swelling by instantaneous decompression toward vacuum. Gradient Activity Report, University of Technology of Compiegne UTC N° CR/89/103, industrial SILVA-LAON Partner.

|

|

|

|

|

Allaf T (2013). Application de la Détente Instantanée Contrôlée pour l'Eco-Extraction des Produits Naturels: Intensification & Combinaison. Thèse de doctorat, Université d'Avignon et des pays de Vaucluse, France. Available at:

View

|

|

|

|

|

Allaf T, Allaf K (2014). Closing Remarks: Instantaneity and Autovaporization. In: Allaf T., Allaf K, editors. Instant Controlled Pressure Drop (D.I.C.) in Food Processing, From Fundamental to Industrial Applications. Food Engineering Series. Springer, NY. pp. 177-178.

Crossref

|

|

|

|

|

Benatallah L, Zidoune MN, Michon C (2012). Optimization of HPMC and water addition for a gluten-free formula with rice and field bean based on rheological properties of doughs. International Review of Chemical Engineering-Rapid Communications 4(5):474-481.

|

|

|

|

|

Besombes C, Berka-Zougali B, Allaf K (2010). Instant Controlled Pressure Drop extraction of lavandin essential oils: Fundamentals and experimental studies. Journal of Chromatography A 1217(44):6807-6815.

Crossref

|

|

|

|

|

Bourekoua H, Benatallah L, Zidoune MN, Rosell CM (2016). Developing gluten-free bakery improvers by hydrothermal treatment of rice and corn flours. LWT-Food Science Technology 73:342-350.

Crossref

|

|

|

|

|

Bourekoua H, RóżyÅ‚o R, Benatallah L, Wójtowicz A, Åysiak G, Zidoune MN, Sujak A (2018). Characteristics of gluten-free bread: quality improvement by the addition of starches/hydrocolloids and their combinations using a definitive screening design. European Food Research and Technology 244(2):345-354.

Crossref

|

|

|

|

|

Calle J, Benavent-Gilb Y, Rosell CM (2020). Development of gluten free breads from Colocasia esculenta flour blended with hydrocolloids and enzymes. Food Hydrocolloids 98:105243.

Crossref

|

|

|

|

|

Delgado-rosas M, Sobolik V, Allaf K (2006). Texturation de la poudre de maltodextrine par détente instantanée contrôlée. Sciences des Aliments. International Journal of Food science and Technology 26(1):103-111.

Crossref

|

|

|

|

|

Do Nascimento AB, Rataichesck Fiates GM, Teixeira E (2017). We want to be normal! Perceptions of a group of Brazilian consumers with coeliac disease on gluten-free bread buns. International Journal of Gastronomy and Food Science 7:27-31.

Crossref

|

|

|

|

|

Duong TC, Al Haddad M, Rezzoug Z, Laurent Lefevre L, Allaf K (2008). Dehydration by successive pressure drops for drying paddy rice treated by instant controlled pressure drop. Drying Technology 26(4):443-451.

Crossref

|

|

|

|

|

Food and Agriculture Organization (FAO) (1982). Les graines de légumineuses dans l'alimentation humaine. Etude FAO: Alimentation et nutrition 2ème édi, Rome. Italie.

|

|

|

|

|

Gallagher E, Gormley TR, Arendt EK (2004). Recent advances in the formulation of gluten-free cereal based products. Journal of Food Science and Technology 15(3-4):143-152.

Crossref

|

|

|

|

|

Gonzales-Barron U, Butler F (2006). A comparison of seven thresholding techniques with the k-means clustering algorithm for measurement of bread crumb features by digital image analysis. Journal of Food Engineering 74(2):268-278.

Crossref

|

|

|

|

|

Goupy J (2013). Introduction aux plans d'expériences. 5ème édi. Dunod, Paris, France. Available at:

View

|

|

|

|

|

Granato D, de Araújo Calado VM (2014). The use and importance of design of experiments (DOE) in process modelling in food science and technology. In: Mathematical and Statistical Methods in Food Science and Technology, 1-18. Wiley, Hoboken.

Crossref

|

|

|

|

|

Habba A, Allaf K (1997). Instrumental measurement of the cooked rice texture, comparative study between the viscoelastograph and the texturometer, First European Congress Chemical Engineering, Florence, Italy.

|

|

|

|

|

Hager AS, Arendt EK (2013). Influence of hydroxypropylmethylcellulose (HPMC), xanthan gum and their combination on loaf specific volume, crumb hardness and crumb grain characteristics of gluten-free breads based on rice, maize, teff and buckwheat. Food Hydrocolloids 32(1):195-203.

Crossref

|

|

|

|

|

ISO (2009). Method 712: Cereals and cereal products. Determination of moisture content. Available at:

View

|

|

|

|

|

ISO (2010). Method 2171: Cereals, pulses and by-products. Determination of ash yield by incineration. Available at:

View

|

|

|

|

|

Kawamura-Konishi Y, Shoda K, Koga H, Honda Y (2013). Improvement in gluten-free rice bread quality by protease treatment. Journal of Cereal Science 58(1):45-50.

Crossref

|

|

|

|

|

Kristiawan M, Sobolik V, Allaf K (2004). Etude comparative d'extraction de l'huile essentielle des fleurs d'ylang-ylang. In: Proceedings 16èmes rencontres scientifiques et technologiques des industries alimentaires et biologiques - AGORAL. Montpellier, France. AGORAL -Montpellier, France.

|

|

|

|

|

Lamacchia C, Camarca A, Picascia S, Di Luccia A, Ginafrani C (2014). Cereal based gluten-free food: how to reconcile nutritional and technological properties of wheat proteins with safety for celiac disease patients. Nutrients 6(2):575-90.

Crossref

|

|

|

|

|

Lebwohl B, Sanders DS, Green PHR (2018). Celiac disease. The Lancet 391(10115):70-81.

Crossref

|

|

|

|

|

Lionetti E., Catassi C (2011). New clues in celiac disease epidemiology, pathogenesis, clinical manifestations, and treatment. International Reviews of Immunology 30(4):219-231.

Crossref

|

|

|

|

|

Louka N., Allaf K (2002). New process for texturing partially dehydrated biological products using Controlled Sudden Decompression to the vacuum. Application on potatoes. Journal of Food Science 67(8):3033-3038.

Crossref

|

|

|

|

|

Makharia GK, Verma AK, Amarchand R, Bhatnagar S, Das P, Goswami A, Bhatia V, Ahuja V, Datta Gupta S, Anand K (2011). Prevalence of celiac disease in the northern part of India: a community based study. Journal of Gastroenterology and Hepatology 26(5):894-900.

Crossref

|

|

|

|

|

Masure HG, Fierens E, Delcour JA (2016). Current and forward looking experimental approaches in gluten-free bread making research. Journal of Cereal Science 67:92-111.

Crossref

|

|

|

|

|

Mohammadi M, Azizi MH, Hosseini H, Tirang RN, Mortazavian AM (2015). Development of gluten-free bread using Guar gum and Transglutaminase. Journal of Industrial and Engineering Chemistry 21:1398-1402.

Crossref

|

|

|

|

|

National Council of Food (CNA) (2009). Avis sur le développement des nouvelles technologies dans la fabrication, le conditionnement et la conservation des denrées alimentaires: conséquences, responsabilité des opérateurs et acceptabilité sociale. Avis n° 65:3-19. Available at :

View

|

|

|

|

|

Nguyen TH (2015). Etude expérimentale et modélisation du procède de séchage des végétaux. Thèse de doctorat, Université de La Rochelle. France. Available at:

View

|

|

|

|

|

Onyango C (2016). Starch and modified starch in bread making: A review. African Journal of Food Science 10(12):344-351.

Crossref

|

|

|

|

|

O'Shea N, Arendt E, Gallagher E (2014). State of the art of gluten-free research. Journal of Food Science 79(6):1067-1076.

Crossref

|

|

|

|

|

Pilatowski I, Mounir S, Haddad J, Duong TC, Allaf K (2010). The Instant Controlled Pressure Drop Process as a New Post-harvesting Treatment of Paddy Rice: Impacts on Drying Kinetics and End Product Attributes. Food Bioprocess Technology 3:901-907.

Crossref

|

|

|

|

|

Phongthai S, D'Amico S, Schoenlechner R, Rawdkuen S (2016). Comparative study of rice bran protein concentrate and egg albumin on gluten-free bread properties. Journal of Cereal Science 72:38-45.

Crossref

|

|

|

|

|

Prameswari IK, Manuhara GJ, Amanto BS, Atmaka W (2018). Effect of water volume based on water absorption and mixing time on physical properties of tapioca starch-wheat composite bread. Journal of Physics: Conference Series 1022:012029.

Crossref

|

|

|

|

|

Setyopratomo P, Fatmawati A, Allaf K (2009). Texturing by Instant Controlled Pressure Drop (DIC) in the production of cassava Flour: Impact on Dehydration Kinetics, Product physical properties and Microbial Decontamination. Proceeding of the Word Congress on Engineering and Computer Science 1:1-6.

|

|

|

|

|

Verni M, Coda R, Rizzello CG (2019). The use of faba bean flour to improve the nutritional and functional features of cereal-based foods: Perspectives and future strategies. In book: Flour and breads and their fortification in health and disease prevention. Academic Press 37:465-475.

Crossref

|

|