The aim of this study was to identify the storage conditions that warrant the optimum quality of the butter of P. butyracea. An experimental design was set up to study the effects of kernel boiling, the packaging material and the storage duration on the colour, saponification value and unsaponifiable fractions, acid and peroxide values and the iodine index of the butter of P. butyracea. The quality parameters of the butter vary significantly according to the storage conditions of the kernels. For all samples, the acid value increased significantly during the storage varying from 0.08 to 0.99 mg KOH/g and from 0.08 to 0.91 mg KOH/g for the kernels boiled and dried and for the kernels dried directly without boiling respectively. The peroxide value of the butter remains quite stable during the first 6 months of storage. The most significant modification occur between 6 and 12 months where an increasing from 3.82 to 15.20 meq O2/kg was recorded for this parameter. The highest values of acid and peroxide value ​​were observed in butter extracted from the kernels stored in basket. The iodine index, the saponification and unsaponifiable content of the butter were affected in various extent. Overall, the kernels boiled prior to drying, stored in jute bag for a duration less than six months provided a butter with optimum quality characteristics.

Traditional foods contribute to food security of millions of poorest people in Africa and to the preservation of the biological diversity of forest resources (Vantomme, 1999).

Pentadesma butyracea Sabine (Clusiaceae) is a ligneous forest species of multipurpose uses. It is widely distributed in Africa from Guinea-Bissau to the West of the Democratic Republic of Congo. The plant is known as “tallow tree” or “butter tree” in English, “arbre à suif” or “arbre à beurre” in French, “Krinda” in Côte d'Ivoire, “Abotoasebie” in Ghana, “Agnuhé” in Gabon and “Kpangnan” or “Sesseido” in Benin.

P. butyracea is found in the centre and northern part of Benin in forest galleries and along water ways (Avocèvou-Ayisso et al.,

2011; Natta et al.

2010). The fresh kernels consumed like kola (Sinsin and Sinadouwirou 2003) are rich in edible butter similar to shea butter (Tchobo et al., 2007). The

P. butyracea butter is generally extracted by traditional processing methods that involve roasting, churning and boiling of kernels. The resulted crude butter is sold in local markets and used for dietary and medicinal purposes. The fatty acid profile of

Pentadesma butter is similar to that of the sheanut butter. However the content of unsaponifiable of the shea butter is higher than that of

P. butyracea (Tchobo et al., 2013). The typical fatty acid composition of

P. butyracea is (in mol-%) palmitic acid (C16) 3.6, stearic acid (C18) 47.00, oleic acid (C18:1) 52.00, linoleic acid (C18:2) 0.7, linolenic acid (C18:3) 0.2, arachidic acid (C20) 0.1 and others (Tchobo et al., 2009). The presence of five triacylglycerols (POO, POS, OOO, SOO, SOS), was observed in

P. butyracea butter. SOO and SOS were the predominant triacylglycerols. The absence of tristearin (SSS) and a low content of triolein (OOO) were observed despite the high content of stearic and oleic acids. The triacylglycerol SOS was the main triacylglycerol with a concentration of over 50% whereas the SOO content varied between 35 and 45% (Tchobo et al., 2009). The social and economic values of

P. butyracea were the subject of a study by Avocèvou-Ayisso and Sinsin (2009). The authors indicated that the various organs of the plant (kernels, leaves, flowers, bark, and roots) are used in food, cosmetic and for therapeutic purposes. Part of the derived butter, is exported towards the neighbouring countries (Togo) and the other sold at the regional markets or used to satisfy the domestic needs (Sinsin and Sinadouwirou, 2003).

In Benin, the harvesting period of the fruits of P. butyracea coincides with the raining season ((Sinsin and Sinadouwirou, 2003). After fruits collection, the women processors extract the kernel which can be stored for duration up to two years before processing. Our recent investigations revealed that the kernels undergo various pre-treatments such as boiling, sun drying and roasting before storage (Ayegnon et al., 2015). The pre-treated kernels are stocked in jute bags, in bowls, in the baskets and sometimes on the flour. During the storage, the kernels can undergo various deteriorations, which are susceptible to alter the quality of the seed while inducing biochemical modifications in the derived butter. Very few works investigated the effects of the storage process on the quality of P. butyracea kernels and derived butter. The objective of this work was to evaluate the effect of storage conditions on the kernels characteristics and on the quality of a derived butter. More specifically, the study evaluated the effects of three storage variables that is storage duration, the pre-treatments and the packaging materials on the acid and peroxide values, the saponification value, the unsaponifiable fraction of the butter, the iodine index and the colour characteristics of the Pentadesma butter.

Plant material

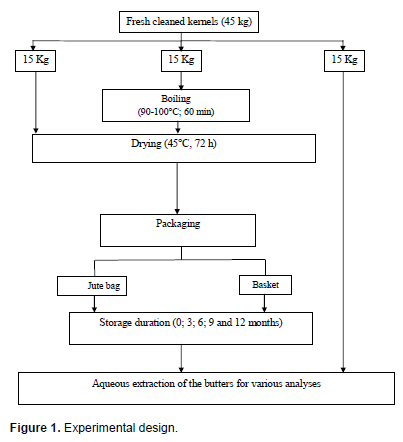

Fresh fruits of P. butyracea were collected from May to June 2013 in the forest galleries of Péperkou village in the community of Toucountouna (10°20′ - 10°45′ N and 1°10′ - 1°40′ E) located in the Northwest of Benin. Eighty kilograms of P. butyracea fruits were randomly collected from different trees of P. butyracea. The fruits were stored in a dark cool box at 4°C and transported to the laboratory for analysis. In the laboratory, the fruits were de-pulped and kernels were cleaned to obtain fresh kernels which undergone various treatments prior to storage (Figure 1).

Experimental design

An experimental design with three factors that is storage duration, the pre-treatments and the packaging materials was used to study the effects of storage conditions on the P. butyracea kernels and the derived butter quality. The storage duration varied from 0 to 12 months and the kernel pre-treatments includes the boiling and the drying. The packaging materials included the jute bag and the basket container. The boiling was performed at a temperature of 90-100°C during 60 min and kernel drying was done at a temperature of 45°C during 72 h. Samples were stored at ambient temperature (temperature: 29.5°C; relative humidity 65±3%). The responses were moisture content, the acid and peroxide values, the saponification value, the unsaponifiable fraction of the butter, the iodine index and the colour characteristics of the butter.

Characterisation of the kernels during storage

Samples of P. butyracea kernels were withdrawn at different storage duration and analyzed for their moisture content (AOAC, 2002). The rate of the kernels deterioration during storage was determined by counting the number of kernels deteriorated among a subsample of hundred kernels taken randomly. ¶The counting was repeated three times and the average values were reported.

Oil extraction

Butter was extracted using the traditional procedure (Ayegnon et al., 2015). The kernels are sorted and crushed. Approximately 300 g of crushed kernels were roasted at 120°C during 30 min. The roasted kernels were ground into fine paste. Some tepid water was added and the mixture was churned for 2 h using a mixer (Kenwood KM 280 series, 900W, china). The generated cream is washed with water, to yield the raw butter which was heated at a temperature of 120-130°C. The derived oil was filtered and cooled to generate butter. The butter was preserved at 4-7°C in the refrigerator until various laboratory analyses.

Physicochemical analyses of the butter

Colour measurements were performed using the chromameter Konica Minolta (CR410). Results were expressed as L* (brightness) and b* (yellowness). The colour coordinates of the white ceramic standard are: Y = 86.10, X = 0.3194, y = 0.3369. Various chemical analyses were performed as well. Thus, the saponification value was determined according to the standards methods ISO 3657 (2006). The unsaponifiable fraction was determined after treatment with a solution of ethanolic potassium hydroxide and extraction by diethyl ether (NB ISO 3596, 2006); the acid and peroxide values and the iodine index were assessed by titration using NB ISO 3960, 2006; NB ISO 3961, 2006; NB ISO 660, 2006 methods respectively.

Statistical analysis

Statistical analysis were performed using the statistical program SPSS16.00 (SPSS, Chicago, IL, USA) and the one-way ANOVA model was used applying the Tukey’s post-hoc test to evaluate significant difference among means at p < 0.05.

Effects of the storage conditions on the kernels quality

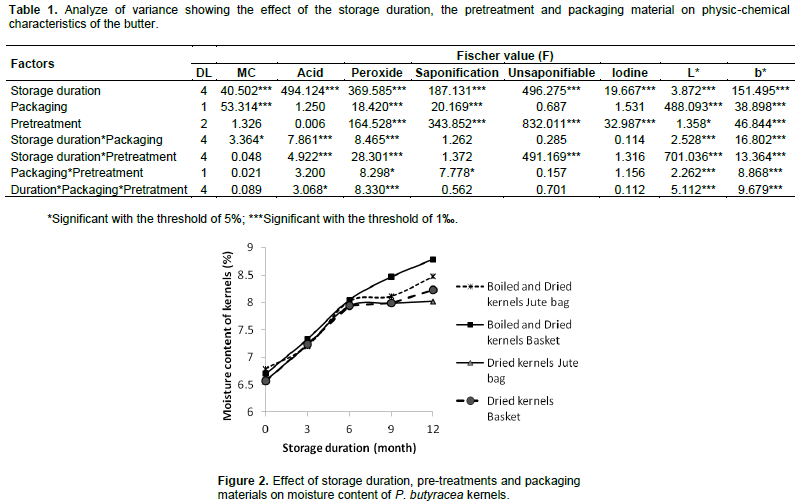

The effects of factors that is kernels pre-treatments, packaging material and the storage duration on the kernels moisture content and the quality parameters of the derived butter are presented in Table 1. The storage duration and the pre-treatments applied (directly dried kernel, boiled and dried kernel) significantly affected the kernel moisture content which increased from a mean value of 6.68% to 8.51% for all treatments after twelfth months of storage. No significant difference could be observed in the moisture content of the kernels stored in jute bag and those stored in basket along the storage duration (Figure 2) In a study by Aïssi et al. (2012), roasted kernels, and boiled and dried kernels of P. butyracea stored for 24 months reached similar levels of moisture content (7.85 and 8.24% respectively). Increased level of moisture content could lead to kernels deterioration as a result of increasing microbial and enzymatic actions. We inspected the kernels throughout the storage duration and observed that samples stored for longer duration showed higher rate of kernels deterioration. There is a correlation between kernel moisture content and the propor-tion of seed damaged (r = 0.63, p≤ 0.001). The highest rate of kernels degradation was recorded in samples boiled and stored in the basket whereas much as 31-33% of kernels were damaged after 12 months of storage. Indeed, cumulative to increased level of moisture content, insect attacks favoured by kernel cracking during boiling and subsequent drying may accentuate seed damage during storage.

Effects of the storage conditions on acid and peroxide values of derived butter

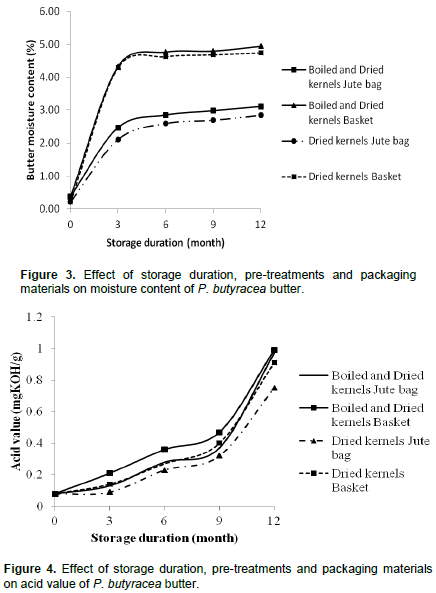

The butter moisture content was affected by the kernel storage duration and by the kernel pre-treatments. Longer kernel storage resulted in higher humidity in the derived butter. Such increase in the product water content may be detrimental to the butter quality since it may favour various biochemical deterioration processes. Butters extracted from the kernels stored in the basket exhibited higher moisture content compared to those from kernels packed in jute bag due to high exposure of kernel to the relative humidity (Figure 3). The acid value of the butter was significantly affected by the storage duration (P≤0.001) and the interaction between storage duration and packaging materials (storage duration*packaging).. Figure 4 shows the trend in the acid value of the butter as function of the storage duration with respect to various pre-treatments and packaging materials. The butter acid value was similar for all treatments at the beginning of storage and averaged to 0.08 mg KOH/g. This value increased (P≤0.001) to an average value of 0.95 mg KOH/g of butter after twelfth months of storage. For all samples, the acid value increased slowly in the storage period between 0 and 9 months and increased sharply thereafter. Studies on shea butter also revealed an increase in the fatty acid value as a result of longer kernel storage (Nkouam et al., 2007). Indeed, high acid value in the butter samples suggests an increase in the free fatty acids which may result from lipid hydrolysis. High moisture content of butter is favourable to such phenomenon and we found a significant correlation between the butter moisture content and its acid value (r = 0.49, p≤ 0.01). Mendez and Falque (2007), reported an increase in acidity of oil stored in PET plastic. Kapseu et al. (2005) indicated that the acid value of shea butter increases with the storage duration and the treatment conditions of the shea fruits. The authors assigned this increase to physiological activities in the fruits. During storage, fatty acids are degraded to produce some energy and precursors for the synthesis of new molecules. Various studies on other oleaginous kernels such as the works of Kapchie (2005) on the aiélé fruits (Canarium Schweinfurthii Engl.) and researches by Anhwange et al., (2010) on Citrus lanatus revealed that longer kernel storage resulted in an increased in level of acid value in the oil.

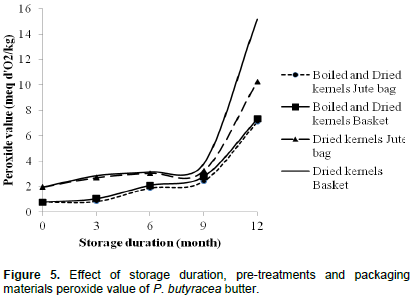

All the factors studied significantly affected the peroxide value of the butter. The analysis of variance revealed significant (P≤0.001) effects of the kernel pre-treatments, the packaging materials, the storage duration, and their interaction on the peroxide value (Table 1). Figure 5 shows the trend in the peroxide value of the butter as function of the storage duration with respect to various pre-treatments and packaging materials. Overall, the peroxide value of the butter increased with the storage duration for all treatments. During the storage, the modification pattern of the peroxide was comparable to that of the acid value. Notably, there was a slow increase between 0 and 9 months of storage followed by a sharp increase till the twelfth month of preservation. Butters extracted from kernels boiled before drying and showed lower peroxide value compared to those from kernel dried without boiling. During the heating process of kernels, denaturation of native lipases may occur, which would have limited the oxidation of fatty acids in the butters extracted from the boiled kernels. The mean peroxide value increased from 0.84 to 7.32 meqO2 / kg in butter extracted from boiled and dried kernels while it varied from 2.72 to 15.20 meqO2 / kg in butter from kernels dried without boiling after 12 months of storage. Values obtained in this study are similar to findings by Aïssi et al (2011) who reported a value of 0.83 meqO2 / kg for butters extracted from boiled and dried kernels of P. butyracea and 1.00 meqO2 / kg for the butters from roasted kernels. Mégnanou and Nianké (2013) found a modification in the peroxide value of stored shea butter in the range of 2.79 to 10.30 meq O2/kg within four weeks of storage. In this study, the peroxide value found in butter extracted from kernels dried without boiling after 12 months of storage which is higher than the tolerated value in the cosmetic and food sectors which are 10 meq O2/kg and 15 meq O2/kg respectively (Codex Alimentarius, 2006). Indeed, when the concentration of peroxide reaches a certain level, complex changes occur with the formation of ketones, aldehydes and hydroxyl groups which are volatile and mainly responsible for the off-flavours (rancidity) and odours (Abdulrahim et al., 2000).

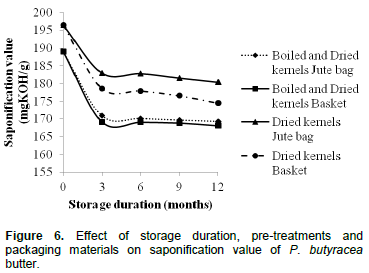

Effects of the storage conditions on the saponification value and unsaponifiable fraction of the butter

The saponification value refers to the average length of the fatty acid chains which make up fat. It is an indicator of the soap making ability of oil. High saponification value indicates the presence of high percentage of fatty acids and triacylglycerol in the oil (Omolara et al., 2011). The present study revealed significant (P≤0.001) effects of the three studied factors on the saponification value of the butter extracted from the stored kernels (Table 1). Figure 6 shows the trend in the saponification value of the butter as function of the storage duration with respect to various pre-treatments and packaging materials. There is a drastic decrease in the saponification components of the butter during the first three months of storage. No significant change occurred in this butter parameter afterward. The saponification value decreased from 188.98 to 168.05 mg KOH/g in butter extracted from boiled and dried kernels over 3 months of storage. It varied from 196.46 to 174.53 mg KOH/g in butter extracted from kernels dried without boiling during the same storage period. Clearly, butters from kernels boiled prior to drying showed low levels of saponification value compared to those from kernels dried without boiling whatever the storage duration. Our results are similar to findings by Aïssi et al. (2011). The saponification values found in our butters are in the range between 160 and 195 mg KOH/g of butter, which falls in the normal interval recommended by the Regional Technical Committee (RTC, 2006) for vegetable oils of good quality. Also, our data are similar to the saponification values reported for common oils such as soya bean (189 - 195 mg KOH/g), peanut (187 - 196 mg KOH/g) and cotton seed oil, (189 - 198 mg KOH/g) (Codex Alimentarius, 1993). Nevertheless, saponification values found for P. butyracea butter in this study are higher than that of shea butter (Warra et al., 2011) indicating that this kind of butter has potential to be used in the cosmetic industry for soap making.

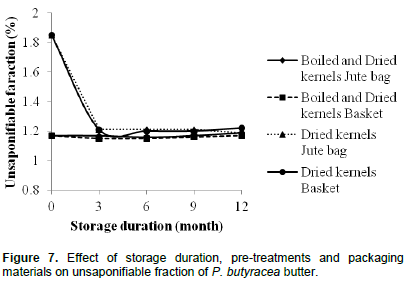

The analysis of variance revealed significant effects of the kernel pre-treatments, the storage duration and the interaction pre-treatments * storage duration (P≤0.001) on the unsaponifiable fraction of the derived butter (Table 1). The type of packaging materials used did not affect (P˃0.05) the unsaponifiable fraction. Figure 7 shows the trend in the unsaponifiable fraction of the butter as function of the storage duration with respect to various pre-treatments and packaging materials. Prior to storage, the kernels boiling resulted in a sharp decrease in the butter unsaponifiable fraction which remain unchanged during storage.

Reduction of thermo labile compounds such as tocopherols, carotenoids, triterpene alcohol, sterols, phenolics that account for unsaponifiable butter fractions may be reason for this reduction. Indeed, these substances contained in unsaponifiable fraction of the oil, have antioxidant and other health related benefits in animals and in human subjects and are useful in softening the skin (Goreja, 2004; Kochhar et al., 2000). During the storage course, the unsaponifiable fractions in the butter extracted from kernels dried without boiling and decreased within three months of storage (1.85 to 1.2%) and remain invariable afterwards. Clearly, thermal treatments are not favourable for unsaponifiable components concentration of the butter. Indeed, butters with a high unsaponifiable fraction are preferred for cosmetic and medicinal purposes due to the antioxidant and anti-inflammatory properties of the unsaponifiable fraction compounds such as tocopherols, phenols and sterols (Maranz and Wiesman, 2004; Honfo et al., 2013).

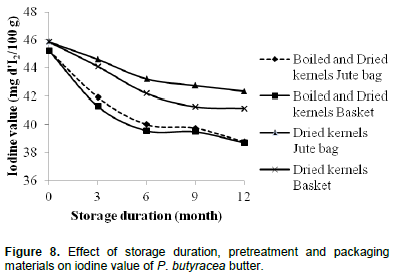

Effects of the storage conditions on the iodine index of the butter

The iodine value expresses the degree of saturation of oil; it is an indicator of the storability of the oil. The higher the iodine numbers of an oil, the higher its degree of unsaponification, and the shorter its shelf-life is (Hui, 1996). The analysis of variance revealed significant (P≤0.001) effects of the pre-treatments and the storage duration of the kernels on the iodine index of the butter (Table 1). Figure 8 shows the trend in the iodine index of the butter as function of the storage duration with respect to various pre-treatments and packaging materials. From this figure, it is clear that butters extracted from kernels dried without boiling exhibited higher iodine values compared to butter from kernels boiled prior to drying whatever the storage duration. During the storage process, the iodine index decreased, varying from 45.23 to 39.58 mgI2 /100 g of butter after storage in the butters extracted from boiled and dried kernels. In the butters extracted from kernels directly dried this value decreased from 45.86 to 41.75 mgI2/100 g. Values of the iodine obtained for butters of P. butyracea in this study are similar to data reported by Kouadio et al. (1990); Adomako et al. (1977) and Tchobo et al. (2013). The decreasing of the iodine index during the storage could be explained by a reduction in the number of double bonds by oxidation or hydrogenation phenomenon. Similarly, these biochemical reactions highly catalyzed by the high hydrothermal applications during boiling would be the main cause of discrepancy in iodine values of butters extracted from boiled and non-boiled kernels.

Interestingly, iodine values obtained in this study are in agreement with the norm required for butter at the international level (58-72 mgI2 /100 g of butter) (NBF 01-005, 2006). Likewise, the iodine values obtained for all samples in this study are consistently below 100 which allows classifying the P. butyracea butter in the category of non-drying oil which are useful in the production of soaps (Asuquo, 2008; Warra et al., 2013).

Effects of the storage conditions on the colour characteristics of the butter

There are significant (P≤0.001) effects of kernels pre-treatments, packaging materials and storage duration on the brightness (L*) and yellowness (b*) of butter (Table 1). In addition, the linear and the interactive effects of these factors were significant with respect to the two parameters mentioned. Figure 9 shows the trend in the brightness of the butter as function of the storage duration with respect to various pre-treatments and packaging materials. The brightness of the different types of butters tend to decrease during the storage. In opposite, the yellowness index increases (Figure 10). Kernels stored in jute bags exhibited relatively higher values for the yellowness index.

Similarly, butters extracted from the boiled and dried kernels showed a yellowness index relatively higher than butter from directly dried kernels. The butter of P. butyracea is naturally yellow with bright colour and these colour characteristics are preferred by consumers (Ayegnon et al., 2015). Chukwu and Adgidzi (2008) found that the colour of shea butter varies, depending on the processing technique, in particular on the temperature applied during processing. Several studies have underlined the difference between the preparation modes of beige and yellow shea butters and the different sensorial characteristics associated (Mégnanou, 2008). Clearly, this study revealed that longer storage duration is favourable to the butter yellowness but detrimental to its brightness.

The storage duration, the pre-treatments and the packaging materials of the kernels of P. butyracea affect the quality characteristics of the derived butter. Particularly, the colour, the peroxide and the acid values, the iodine index, the saponification and unsaponifiable fractions of the butter are affected in various extents. The packaging materials currently used in the different production sites of Benin to store the P. butyracea kernels affect the quality of the derived butter. More specifically, the basket is less effective, compared to the jute bag, in preserving the quality of the butter within 6 months of storage. Overall, this study shows that it is advantageous to treat the P. butyracea kernels by boiling before storage.