ABSTRACT

The aim of this study was to determine the effects of seven different stabilizers on some properties of set-type yogurt. Stabilizers used were sodium caseinate, gelatin, carrageenan, xanthan gum, guar gum, locust bean gum (LBG), native corn starch. For the control group, no stabilizer was added. During the storage period, while the fat and pH values of the yoghurt samples were reduced, the stabilizers had no effects on the physical and chemical properties. The color values were affected by stabilizers and storage period at p<0.01 level. Stabilizers, except LBG, adversely affected the development of Streptococcus thermophilus but did not show the same effect on Lactobacillus delbrueckii subsp. bulgaricus. Control sample was the most favorite example in sensory evaluations. The microstructural properties of yogurt samples containing gelatine, xanthan gum, guar gum and locust bean gum were quite different as compared to the control sample. The results of this study indicate that sodium caseinate and gelatin were the most suitable stabilizers that could be used in the production of set yoghurt.

Key words: Yogurt, stabilizer, gum, physical and chemical properties, microstructure.

Yogurt, a functional food, is one of the most consumed fermented dairy products in the world (Buttriss, 1997; Mckinley, 2005; Weerathilake et al., 2014). The texture of yogurt is as important as its taste and flavor in terms of consumer preferences. However, the properties of the milk used in yogurt production, the production and storage conditions or the transportation to far sales points can lead to textural defects such as viscosity variations and syneresis (Trachoo, 2002; Hematyar et al., 2012). Various stabilizers are used to prevent these problems and to create desirable textural characteristics (Keogh and O’Kennedy, 1998; Athar et al., 2000; Mohammadifar et al., 2007).Stabilizers, also called thickeners, gelling agents or hydrocolloids, can be obtained from different sources including animal connective tissues, sea and land plants and microorganisms (Imeson, 2010).

They have gelling, thickener and stabilizer properties (Lal et al., 2006; Tamime and Robinson 2007).Sodium caseinate and gelatin increase the density of the protein network in the gel microstructure (Remeuf et al., 2003; Amatayakul et al., 2006; Supavititpatana et al.,2009). Many researchers reported that yogurt fortification with sodium caseinate or gelatin resulted in a stronger network, higher viscosity and less syneresis (Modler et al., 1983; Athar et al., 2000; Guzmán-González et al., 2000; Schmidt et al., 2001; Remeuf et al., 2003; Ares et al., 2007; Damin et al., 2009).When starch is heated, it swells by taking water and increases solution viscosity by forming a gel after a certain temperature. Therefore, the addition of the starch into yogurt enhances the viscosity (Schmidt et al., 2001; Williams et al., 2003; Mishra and Rai, 2006; Ares et al., 2007).

Athar et al. (2000) ranked stabilizers as cornstarch, gelatin, pectin, guar gum, CMC, carrageenan and sodium alginate according to the reduction rates of syneresis when compared with the control group. The characteristics of yogurt that natural wheat starch (NWS) is added to, are similar to those of yogurt with gelatin; therefore, NWS may be preferred as stabilizer in set-type yogurts (Schmidt et al., 2001).Guar gum, xanthan gum and locust bean gum (LBG) are used as thickener in food industry (Tamime and Robinson 2007). They enhance the texture by increasing the viscosity of continuous phase and reduce syneresis (Hematyar et al., 2012).

Locust bean gum has synergic effects with other stabilizers to reduce serum separation and increase viscosity (Köksoy and Kilic, 2004). Ünal et al. (2003) reported that LBG concentrations above 0.02% decreased water holding capacity (WHC) and viscosity, while it increased syneresis. 0.1% of guar gum in yogurt achieved the best result for low acidity and low pH (Mehmood et al., 2008). El-Sayed et al. (2002) argued that the xanthan gum and its mixture with other stabilizers significantly increased the viscosity of cow milk yogurt and reduced syneresis. They also pointed out that yogurt including 0.01% of xanthan gum was the most favorite in sensorial evaluation.

Carrageenan is used as gelling and has different forms. In the presence of calcium, κ-carrageenan forms a stiff and brittle gel, whereas ι-carrageenan forms a soft gel and λ-carrageenan will not form a gel, but acts as a thickener (Glicksman, 1987). SaÄŸdıç et al. (2004) stated that 0.01 and 0.03% of κ-carragenan could be used in yogurt production.

The aim of this study was to investigate the effects of different stabilizers such as sodium caseinate, gelatin, carrageenan, xanthan gum, guar gum, locust bean gum and native corn starch on some characteristics of plain set-type yogurt.

Raw cow’s milk, starter culture and skim milk powder were obtained from the dairy farm of Agriculture Faculty. Stabilizers were supplied from ORKÄ°M (Chem. Subst. Inc.), Turkey.

Preparation of yogurt

The milk was homogenized at a pressure of 20 Mpa (ALFA LAVAL,separations technique GMBH) after being passed through the clarifier (Model ALFA-LAVAL model 313 T, centrifugal clarifier) and divided into eight parts. In each portion, 3% skimmed milk powder and a different stabilizer were added. Stabilizers were added to the milk, mixing with skimmed milk powder. Prepared mixes were heat treated at 80°C for 20 min, then cooled to 44±1°C and inoculated with 20 g/100 L yogurt culture (Streptococcus thermophilus, Lactobacillus bulgaricus; DVS culture, Valiren, Mayasan).

They were filled into glass jars of 300 mL and incubated until it reached pH 4.7±0.1 at 44±1°C. The yogurts that completed incubation were stored in cold storage at 4±1°C. Analyzes were performed on the 1st, 7th, 14th and 21th days of the storage.Sample codes for yogurt samples were as follows: C (the control group, without stabilizer), SC (0.5% sodium caseinate), G (0.3% gelatin), CR (0.025% carrageenan), XG (0.015% xanthan gum), GG (0.02% guar gum), LBG (0.02% locust bean gum) and NCS (1.25% native corn starch). The ration of stabilizer used was determined by pretesting and regarding the ratios used in various studies (El-Sayed et al., 2002; Ünal et al., 2003; Ares et al., 2007; Soukoulis et al., 2007; Hematyar et al., 2012).

Physical and chemical analyses

Yogurt samples were stored at 4°C for 21 days and all measurements were performed on days 1, 7, 14 and 21. The total solids and ash were determined by gravimetric method and the fat by the Gerber method. Yogurt samples were analyzed for protein by the mikro Kjeldahl method (IDF, 1993). Syneresis and WHC were determined respectively by the methods described by Sahan et al. (2008) and Sodini et al. (2004). Viscosity was determined using Poulten RV-8 model viscometer at 20 rpm. The pH values were measured using a digital pH meter (WTW 340-1, Germany). The research was conducted in two repetitions and the analyses were done in parallel.

Color

The color of yogurt was measured using Minolta Colorimetre (CR-200 Minolta Colorimeter, Osaka, Japan). The colorimeter used L (lightness), a (redness) and b (yellowness) scales (Sert et al., 2010).

Microbiological analysis

M17 agar (Merck) was used in the S. thermophilus count. Plates were incubated for 48 h at 37°C under aerobic condition. The enumeration of Lactobacilli was performed with MRS agar (Merck) for 72 h at 37°C under anaerobic conditions.

Sensory analysis

The sensory evaluations of the yogurt samples were carried out with a panelist group of 6 staff on the 1st, 7th, 14th and 21st days of the storage period. Odor, appearance, consistency, taste and general acceptability of yogurt samples were assessed by sensory evaluation. The highest score in the evaluation was 9 points and the lowest score was 1 point (9-8: very good, 7-6: good, 5-4: medium, 3-2-1: bad) (Bodyfelt et al., 1988).

Microstructure

About 30 g of the yogurt sample was weighed in the aluminum caps, and dried in the vacuum oven at 70°C and at 3.3 kPa for about 16 h. The samples taken out from the oven were stored until it reached a constant weight in airtight desiccant (containing silica gel as the desiccant) before analysis. Thus, the samples were fully dried. Lentil-sized pieces were cut from dried samples and were analyzed with SEM (Field Emission Scanning Electron Microscope, JEOL JSM- 7001F) after the process of gold plating in the vacuum cabin (Jaya, 2009).

Statistical analysis

The SPSS statistical software program version 13 (SPSS Inc., Chicago, IL, USA) was employed to analyze experimental data and Duncan’s multiple range tests were employed to determine differences between results (SPSS, 2004).

Raw cow’s milk had 11.93% total solid, 3.5% milk fat, 3.31% protein, 0.71% ash, 6.52 pH and 1.031 specific gravity.

Physical and chemical analyses

According to the statistical analysis results, stabilizer and storage period had no effects on the physical and chemical properties of yogurt samples. Only the storage period had a significant effect (p<0.01) on the fat and pH values (Table 1).The dry matter ratio of milk is one of the important factors that determine the physical properties of yogurt. The average dry matter ratio of yogurt samples was found as 13.03%. Smit (2003) stated that the dry matter ratio in commercial yogurts ranged from 13 to 17%. The ash content of yoghurt samples varied between 0.880 and 0.898%. Proteins have water binding properties and reduce syneresis by increasing the water holding capacity of the yogurt (Smit, 2003). The average protein content of yoghurt samples was determined to be 4.01%. Sodium caseinate, gelatin and LBG were found to increase protein values, but this increase was not statistically significant.

The mean values of fat and pH regarding the yoghurt samples were 2.71% and 4.11, respectively. While the stabilizers had no effect on these values, the storage period was effective on fat ratio and pH at p <0.01 level. The lowest fat content (2.28%) was determined on the 21st day of storage. This decrease could be a result of the lipolytic activities of yogurt bacteria during storage. The highest pH value (4.22) was obtained on the 1st day of storage (Figure 1). It was similar in 7, 14 and 21 days. This change in pH was due to the increase in acidity of the yogurt samples during the storage period.The viscosity values of the yogurt samples varied between 4753 (sample GG) and 6432 cp (SC); WHC values were between 53.15 (GG) and 60.92 g/kg (NCS). Although sodium caseinate increased viscosity and WHC values, an increase in WHC value was also observed via natural corn starch; these increases were not statistically significant.

Sample G with the addition of gelatin was different from other samples in terms of various parameters. Syneresis values of sample G decreased rapidly after day 7 and were lower than other samples (Figure 2). The protein and pH levels of sample G quickly decreased (protein from 4.13 to 3.91% and pH from 4.37 to 3.98) during the storage period. It was accordingly considered that components with acidic characteristics that were formed as a result of the breakup of gelatin and lactose by yogurt bacteria decreased syneresis with an increase of water holding capacity. These changes reduced the viscosity of sample G. Supavititpatana (2008) found that as the gelatin ratio in yogurt increased, syneresis values decreased. In addition, Fiszman et al. (1999) reported that gelatin formed double network structure in yogurt and this structure reduced the syneresis values of yogurt.

Color

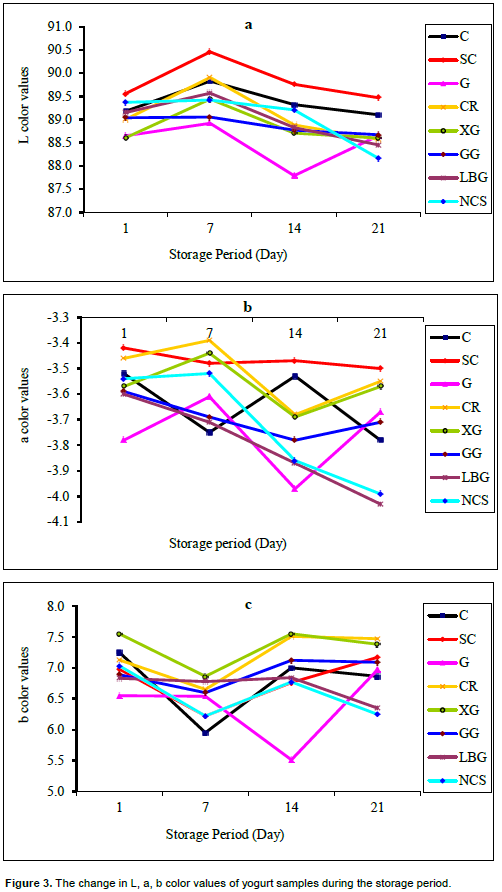

The results of variance analysis indicate that the effect of stabilizer type and storage time on the color values of yogurt samples was found to be significant at the level of p<0.01. The changes in color values of yogurt samples during the storage period are shown in Figure 3a, b and c. The highest L and a values were observed in SC sample. Sodium caseinate created an increase in density of the protein network by increasing protein content(Table 1). Thus, it enabled yogurt to seem whiter by preventing the release of the serum phase from casein network. L values increased on the 7th day, and then a decrease was observed in these values. a Values decreased in parallel with the decrease in L color values. This situation resulted from a spontaneous syneresis in yogurt after the seventh day. The highest b value was determined in XG sample and the lowest value in sample G. Fat levels affected b color value. Yogurt samples showed significant differences in terms of color values. The syneresis ratios of yogurt samples, the color and usage ratio of stabilizer had a significant effect on these differences.

Microbiological analysis

Stabilizer and storage period significantly affected S. thermophilus (p<0.01) and L. delbrueckii subsp. bulgaricus numbers (p<0.05) (Table 2). Stabilizers, except LBG, adversely affected the development of S. thermophilus but did not show the same effect on L. delbrueckii subsp. bulgaricus. This effect could be explained thus: reducing water activity of stabilizers affected negatively, the development of S. thermophilus. S. thermophilus needs higher water activity than L. delbrueckii subsp. bulgaricus. It was considered that the lowest S. thermophilus count in the M sample may be due to the fact that water activity of the medium was lower when compared with other samples regarding the high corn starch concentration used in the M sample. S. thermophilus and L. delbrueckii subsp. bulgaricus counts increased until the 14th day and decreased after 14th day. This decrease might have been due to the decrease in pH values as a result of acidity development.

Sensory analysis

Storage time had no effect on the sensory properties of yogurt samples. Stabilizers were effective at p<0.01 level on appearance, consistency and general acceptability, at p<0.05 on taste. C, SC and NCS samples for appearance and consistency, C sample for taste, and C and SC samples for general acceptability were the most preferred. C sample was the most popular example in sensory evaluations (Table 3).

Microstructure

The microstructure analysis of sample C showed that it had a homogeneous network formed by casein micelle (Figure 4a). The microstructure of sample C is in accordance with the study of Hess et al. (1997), Fiszman et al. (1999), Sanchez et al. (2000), Oh et al. (2007), Jaya (2009) and Rascón-Díaz et al. (2010). Sample SC had a denser network and fewer voids than the control group (Figure 4b). These results are in parallel with some physical and chemical analysis results found in yogurt samples with the addition of Na-caseinate. The microstructure of sample SC was similar to that of Modler et al. (1983).

Sample G had a low porosity (Figure 4c). A number of researchers reported that gelatin could interact with casein and form a denser porosity in yogurt microstructure (Fiszman et al., 1999; Gonçalvez et al., 2005; Ares et al., 2007). This information was supported with a decrease in the syneresis values of the sample G. However, it is in contradiction with viscosity decrease. Modler and Kalab (1983) pointed out that no gelatin was visible in the microscopic appearance of yogurt with 0.5% gelatin and the gel network was similar to plain yogurt. The microstructural analysis of the sample CR showed that the carrageenan had a larger structure as compared to the milk components and the microstructure of yogurt had fewer voids (Figure 4d). Rascón-Díaz et al. (2012) reported that yogurt samples produced by adding carrageenan had a tense structure.

In sample XG (Figure 4e), the xanthan gum particles were bigger than the casein fractions. Consequently, they broke into the network of the casein micelles and created a more heterogeneous structure than the control sample. So, the use of xanthan gum in yogurt increased serum separation values and adversely affected the microstructural properties. The microstructure of sample XG was similar to that of Sanches et al. (2000) but was different from that of El-Sayed et al. (2002). Harwalkar and Kalab (1986) reported that large pores in the protein matrix would promote serum separation.

In the sample GG (Figure 4f), large guar gum particles caused buildup of a heterogeneous structure. The pores were small but their number was high. The guar gum was a neutral stabilizer and there was no electrical interaction with casein micelles (Everett and Leod, 2005). Rascón-Díaz et al. (2010) reported that the guar gum samples showed low porosity and low homogeneity and such a structure had low water holding capacity.

LBG molecules increased porosity and made yogurt structure more heterogeneous (Figure 4g). However, the serum separation values of LBG-added yogurt samples were close to that of the control group. This effect resulted from the fact that LBG had a more thickening function rather than being a gelling agent. Thaiudom and Goff (2003) determined that LBG particles were excluded from the structure formed by casein micelles.

In the samples NCS, casein micelles were closer to each other than those of the control sample and the pores of the network were smaller (Figure 4h). This effect was due to the fact that the starch granules absorbed some of the water in the medium during the heat treatment and the water amount in the pores of the network decreased. Oh et al. (2007) concluded that swollen starch granules appeared as dark globules embedded in the protein network and this structure increased in parallel with the increase in starch concentration.

A variety of stabilizers can be used to improve the textural properties of yogurt. This study was carried out to reveal the effects of various stabilizers on the quality characteristics of set type yogurts. Physical, chemical, color sensory and microstructural properties of yogurt were investigated and the counts of yogurt bacteria were performed during storage period of of 21 days. In conclusion, the yogurts produced without the stabilizer were more favorable in terms of sensory properties. However, Na-caseinate could increase viscosity and water holding capacity and gelatin was capable of being used to reduce serum separation in the event that stabilizer is required for use. Carrageenan, xanthan gum, guar gum, LBG additives alone and in the concentrations used, had no positive effect on the these properties of the yogurt. Sodium caseinate and gelatin were the most suitable stabilizers that could be used in the production of set yogurt.

The authors have not declared any conflict of interests.

REFERENCES

|

Amatayakul T, Sherkat F, Shah NP (2006). Physical characteristics of set yoghurt made with altered casein to whey protein ratios and EPS-producing starter cultures at 9 and 14% total solids. Food Hydrocolloids 20:314-324.

Crossref

|

|

|

|

Ares G, Gonçalvez D, Pérez C, Reolón G, Segura N, Lema P, Gámbaro A (2007). Influence of gelatin and starch on the instrumental and sensory texture of stirred yogurt. Int. J. Dairy Technol. 60:263-269.

Crossref

|

|

|

|

|

Athar IH, Shah MA, Khan UN (2000). Effect of various stabilizers on whey separation (syneresis) and quality of yogurt. Pak. J. Biol. Sci. 3:1336-1338.

Crossref

|

|

|

|

|

Bodyfelt FW, Tobias J, Trout GM (1988). The sensory evaluation of dairy products. Van Nostrand Reinhold, 598, New York.

|

|

|

|

|

Buttriss J (1997). Nutritional properties of fermented milk products. Int. J. Dairy Technol. 50(1):21-27.

Crossref

|

|

|

|

|

Damin MR, Alcântara MR, Nunes AP, Oliveira MN (2009). Effects of milk supplementation with skim milk powder, whey protein concentrate and sodium caseinate on acidification kinetics, rheological properties and structure of nonfat stirred yogurt. LWT-Food Sci. Technol. 42:1744-1750.

Crossref

|

|

|

|

|

El-Sayed EM, Abd El-Gawad IA, Murad HA, Salah SH (2002). Utilization of laboratory-produced xanthan gum in the manufacture of yogurt and soy yogurt. Eur. Food Res. Technol. 215(4):298–304.

Crossref

|

|

|

|

|

Everett DW, McLeod RE (2005). Interactions of polysaccharide stabilizers with casein aggregates in stirred skim-milk yoghurt. Int. Dairy J. 15(11):1175-1183.

Crossref

|

|

|

|

|

Fiszman SM, Lluch MA, Salvador A (1999). Effect of addition of gelatin on microstructure of acidic milk gels and yoghurt and on their rheological properties. Int. Dairy J. 9(12):895-901.

Crossref

|

|

|

|

|

Glicksman M (1987). Utilization of seaweed hydrocolloids in food industry. Hydrobiologia 151/152(1):31-47.

Crossref

|

|

|

|

|

Gonçalvez D, Pérez C, Reolon G, Segura N, Lema P, Gámbaro A, Ares G, Varela P (2005). Effect of thickeners on the texture of stirred yogurt. Alim. Nutr. Araraquara 16:207-211.

|

|

|

|

|

Guzman-Gonzalez M, Morais F, Amigo L (2000). Influence of skimmed milk concentrate replacement by dry dairy products in a low-fat set-type yoghurt model system: Use of caseinates, Co-precipitate and blended dairy powders. J. Sci. Food Agric. 80:433-438.

Crossref

|

|

|

|

|

Harwalkar VR, Kalab M (1986). Relationship between microstructure and susceptibility to whey separation in yoghurt made from reconstituted nonfat dry milk. Food Microstruct. 5:287-294.

|

|

|

|

|

Hematyar N, Samarin AM, Poorazarang H, Elhamirad AH (2012). Effect of gums on yogurt characteristics. World Appl. Sci J. 20:661-665.

|

|

|

|

|

Hess SJ, Roberts RF, Ziegler GR (1997). Rheological properties of nonfat yoghurt stabilized using Lactobacillus delbrucckii ssp. bulgaricus producing exopolysaccharide or using commercial stabilizer systems. J. Dairy Sci. 80(2):252-263.

Crossref

|

|

|

|

|

Imeson A (2010). Food stabilisers, thickeners and gelling agents. Blackwell Publishing Ltd, UK.

|

|

|

|

|

International Dairy Federation (1993). Milk: Determination of the nitrogen (Kjeldahl method) and calculation of the crude protein content. IDF Standard 20B, Brussels: International Dairy Federation.

|

|

|

|

|

Jaya S (2009). Microstructure analysis of dried yogurt: Effect of different drying methods. Int. J. Food Prop. 12(3):469-481.

Crossref

|

|

|

|

|

Keogh MK, Kennedy BTO (1998). Rheology of stirred yogurt as affected by added milk fat, protein and hydrocolloids. J. Food Sci. 63:108-112.

Crossref

|

|

|

|

|

Köksoy A, Kilic M (2004). Use of hydrocolloids in textural stabilization of a yogurt drink, ayran. Food Hydrocolloids 18:593-600.

Crossref

|

|

|

|

|

Lal SND, O'Connor CJ, Eyres L (2006). Application of emulsifiers/stabilizers in dairy products of high Rheology. Adv. Colloid Interf. Sci. 123-126:433-437.

Crossref

|

|

|

|

|

Mckinley MC (2005). The nutrition and health benefits of yoghurt. Int. J. Dairy Technol. 58(1):1-12.

Crossref

|

|

|

|

|

Mehmood ST, Masud T, Mahmood T, Maqsud S (2008). Effect of different additives from local source on the quality of yoghurt. Pak. J. Nutr. 7(5):695-698.

Crossref

|

|

|

|

|

Mishra S, Rai T (2006). Morphology and functional properties of corn potato and tapioca starches. Food Hydrocolloids 20: 557–566.

Crossref

|

|

|

|

|

Modler HW, Kalab M (1983). Microstructure of yogurt stabilized with milk proteins. J. Dairy Sci. 66(3):430-437.

Crossref

|

|

|

|

|

Modler HW, Larmond ME, Lin CS, Froehlich D, Emmons, DB (1983). Physical and sensory properties of yogurt stabilized with milk proteins. J. Dairy Sci. 66:422-429.

Crossref

|

|

|

|

|

Mohammadifar AM, Musavi SM, Williams PA (2007). Study of complex coacervation between β-lactoglobulin and tragacanthin (soluble part of gum tragacanth). Milchwissenschaft. 62:365-488.

|

|

|

|

|

Oh HE, Anema SG, Wong M, Pinder DN, Hemar Y (2007). Effect of potato starch addition on the acid gelation of milk. Int. Dairy J. 17(7):808-815.

Crossref

|

|

|

|

|

Rascón-Díaz MP, Tejero JM, Mendoza-Garcia PG, García HS, Salgado-Cervantes MA (2012). Spray drying yogurt incorporating hydrocolloids: Structural analysis, acetaldehyde content, viable bacteria, and rheological properties. Food Bioprocess Technol. 5(2):560-567

Crossref

|

|

|

|

|

Remeuf F, Mohammed S, Sodini I, Tissier JP (2003). Preliminary observations on the effects of milk fortification and heating on microstructure and physical properties of stirred yogurt. Int. Dairy J.13:773-782.

Crossref

|

|

|

|

|

SaÄŸdıç O, ÅžimÅŸek B, Orhan H, DoÄŸan M (2004). Effect of κ-carrageenan on bacteria and some characteristics of yoghurt. Milchwissenschaft 59(1-2):45-47.

|

|

|

|

|

Sahan N, Yasar K, Hayaloglu AA (2008). Physical, chemical and flavour quality of non-fat yogurt as affected by a β-glucan hydrocolloidal composite during storage. Food Hydrocolloids 22:1291-1297.

Crossref

|

|

|

|

|

Sanchez C, Zuniga-Lopez R, Schmitt C, Despond S, Hardy J (2000). Microstructure of acid-induced skim milk-locust bean gum-xanthan gels. Int. Dairy J. 10(3):199-212.

Crossref

|

|

|

|

|

Schmidt KA, Herald TJ, Khatib KA (2001). Modified wheat starches used as stabilizers in set-style yogurt. J. Food Qual. 24:421-434.

Crossref

|

|

|

|

|

Sert D, Akın N, Dertli E (2010). Effects of sunflower honey on the physicochemical, microbiological and sensory characteristics in set type yoghurt during refrigerated storage. Int. J. Dairy Technol. 64(1):99-107.

Crossref

|

|

|

|

|

Smit G (2003). Dairy Processing. CRC Pres. 2000 Corporate Blvd, NW, Boca Raton FL 33431, USA.

|

|

|

|

|

Sodini I, Remeuf F, Haddad S, Corrieu G (2004). The relative effect of milk base, starter, and process on yogurt texture: A Review. Crit. Rev. Food Sci. 44:113-137.

Crossref

|

|

|

|

|

Soukoulis C, Panagiotidis P, Koureli R, Tzia C (2007). Industrial yogurt manufacture: Monitoring of fermentation process and improvement of final product quality. J Dairy Sci. 90(6):2641-2654.

Crossref

|

|

|

|

|

SPSS Inc. Statistical package for the social sciences SPSS ver., (2004). 13.0 for Windows. Chicago, IL.

|

|

|

|

|

Supavititpatana P, Wirjantoro TI, Apichartsrangkoon A, Raviyan P (2008). Addition of gelatin enhanced gelation of corn-milk yogurt. Food Chem. 106(1):211-216.

Crossref

|

|

|

|

|

Supavititpatana P, Wirjantoro TI, Raviyan P (2009). Effect of sodium caseinate and whey protein isolate fortification on the physical properties and microstructure of corn milk yogurt. CMU. J. Nat. Sci. 8:247-263.

|

|

|

|

|

Tamime AY, Robinson RK (2007). Yogurt science and technology. Boca Raton Boston New York Washington, DC. 35-41.

|

|

|

|

|

Thaiudom S, Goff HD (2003). Effect of κ-carrageenan on milk protein polysaccharide mixtures. Int. Dairy J. 13(9):763-771.

Crossref

|

|

|

|

|

Trachoo N (2002). Yogurt: The fermented milk. Songklanakarin J. Sci. Technol. 24(4):727-734.

|

|

|

|

|

Ünal B, Metin S, Develi Işıklı N (2003). Use of response surface methodology to describe the combined effect of storage time, locust bean gum and dry matter of milk on the physical properties of low-fat set yoghurt. Int. Dairy J. 13(11):909–916.

Crossref

|

|

|

|

|

Weerathilake WADV, Rasika DMD, Ruwanmali JKU, Munasinghe MADD (2014). The evolution, processing, varieties and health benefits of yogurt. Int. J. Sci. Res. Publ. 4:1-10.

|

|

|

|

|

Williams RPW, Glagovskaia O, Augustin MA (2003). Properties of stirred yogurts with added starch: Effects of alterations in fermentation conditions. Aust. J. Dairy Technol. 58:228-232.

|

|