Flavour compounds in fermented garlic were identified by physicochemical analysis and gas chromatography (GC) after pre-treatment. Reducing sugars, acids, polyphenols and 5-hydroxymethyl furfural (5-HMF) were detected in fermented garlic, and 5-HMF was identified to be the key aroma compounds. To further improve the flavour quality of fermented garlic, the influence of pre-treatment method, fermentation temperature and fermentation humidity on the 5-HMF formation was studied, and then single factor tests and response surface methods were employed to optimize the fermentation process. The results showed that the best flavour was obtained when the pre-treatment was done by low temperature freezing, the fermentation temperature was 61.8°C and the humidity was 40.2%. Under the optimum condition, the content of 5-HMF reached 3.6 mg/g with a high quality score of 19.

As a common condiment in dietary cooking, garlic is not only rich in amino acids, vitamins and various trace elements, but also contains 35 kinds of sulphur-containing organic matter (Kimura et al., 2017; USDA, 2018). However, the unique spicy and pungent odour of fresh garlic seriously restricts the development of the garlic industry in China. To improve the taste as well as the nutritional value of the garlic, the fermented garlic gained much attention in the recent years.

Fermented garlic is also called black garlic, or fermented black garlic. Compared with fresh garlic, fermented garlic has stronger antioxidant capacity, which attributes to its richness in protein, sugars, vitamins and various minerals (Kim et al., 2013). In the fermented garlic producing process, a large number of proteins are converted into the essential amino acids, which is easier for absorption of the human body, and has a good promoting effect on enhancing human immunity, alleviating fatigue, and maintaining physical health (Kim et al., 2016; Qiu et al., 2020). Moreover, as an ideal health food, fermented garlic has a sweet35-36 and sour taste, no spicy taste, and can be eaten directly (Wang et al., 2014).

Fermented garlic, as a deeply processed product of garlic, has great economic value due to its unique health-care effect. In recent years, much work had been done to investigate the quality changes of functional ingredients and flavour components. However, the quality factors of fermented garlic have not been determined, and there is no standardized production method for fermented garlic. As a result, the production quality of fermented garlic is uneven. It greatly hindered the development of fermented garlic industry.

In this paper, the content of reducing sugar, acid, polyphenols, 5-HMF and water in different batches of finished fermented garlic was tested to analyse the formation rule of fermented garlic quality, further to identify the key aroma substances of black garlic. The single factor experiment and response surface method were used to optimize the garlic fermentation process. Thus, the flavour of black garlic can be improved, the good quality of black garlic can be guaranteed. This is beneficial to improving the commercial nature of black garlic and provide theoretical basis for the industrial production of black garlic.

Experimental materials

The fresh garlics from the white variety were purchased in the market, which is from Wuhu, Shandong province. The cleaned garlics with skin were placed in the freezer for pre-treatment. And the pre-treatment methods included low temperature freezing, normal temperature preservation, high temperature boiling. Then the garlics were placed in the fermentation cabinet with high temperature and constant humidity for 15 days. The temperature range was controlled from 50 to 90°C, and the humidity range was controlled from 30 to 70%. Next, the garlics were placed in the fermentation cabinet and dried at 55°C by hot air for 3 days. Finally, the finished products were packed (Liang et al., 2015). After fermentation, different batches of black garlic were selected and classified into excellent, good, qualified and unqualified according to the taste comfort (Zhang et al., 2015; Jiang, 2016). The content distribution of reducing sugar, total acid, total phenol, 5-HMF and water in each grade of black garlic was determined respectively to study the influence on taste comfort.

Determination of reducing sugar content

For solution A, Copper sulfate (15 g) and methylene blue (0.05 g) were diluted with distilled water and then transferred to a 1000 mL volumetric flask.

For solution B, potassium sodium tartrate (50 g), sodium hydroxide solution (75 g) and potassium ferrocyanide (4 g) were diluted with distilled water and then transferred to a 1000 mL volumetric flask.

Determination of reducing sugar content was carried out following the Fehling’s solution method in GB/T 5009.7-2016. The garlic sample (5 g) was chopped, ground and diluted with distilled water, and then transferred to a 100 mL volumetric flask for filtration. 5 ml of A, 5 ml of B, and 10 ml of distilled water were added to the conical flask. After the solution was heated to boiling, one group was dropped the sample solution until the blue just fades away as the end of the pre-titration. The other group was dropped the sample solution 1 ml less than the pre-titration, and the titration was continued at the boiling point until the blue just fades away.

The volume consumed of the sample solution was recorded.

Determination of total acid content

The total acid content was determined according to acid-base titration in GB/T 12456-2008. The garlic sample (5 g) was chopped, ground and diluted with distilled water, and then transferred to a 100 mL volumetric flask for filtration. 5 ml filtrate was placed in a 250 ml trigonometric bottle, then 50 ml distilled water was poured into it, and 3 drops of phenolphthalein indicator solution was added. Titration was conducted with 0.1 mol/L sodium hydroxide solution until the solution appeared red, and the volume number of sodium hydroxide standard solution consumed was recorded.

Determination of total phenol content

The heated garlic sample (5 g) was chopped, ground and transferred to a 100 ml volumetric flask with distilled water. Filtrates (0.5 mL), 0.5 mL of Folin Ciocalteu reagent, 1.5 mL of sodium carbonate solution (100 g/L 1, w/v) and 7.5 mL of distilled water were mixed in a 10 mL volumetric flask. The mixture was incubated at 75°C for 10 min, and then placed for 2 to 3 h. The absorbance of the solution was measured at 760 nm.

Determination of 5-HMF content

The spectrophotometry was used to determine the content of 5-HMF (Li et al., 2015). The sample extract (5 mL) was transferred to two tubes containing 5 ml of 4-methylaniline solution. One milliliter of barbituric acid was added to the first tube, while 1 ml of diluted water was added to the second tube as a blank control. Absorbance at 550 nm was measured immediately. The 5-HMF content was calculated as per gram dry weight of the black garlic sample.

Determination of water content

Black garlic samples of a certain weight were dried in a drying oven at 105°C to a constant weight, and the weight difference before and after drying was determined, namely the water content.

Determination of volatile flavour substances

To identify the volatile flavour substances in the finished fermented garlic, an Agilent GC6890 plus system (Agilent Technologies, USA) was used. The specific operations were as follows:

1. Sample treatment: A 5 g sample of black garlic was weighed and ground thoroughly. Then it was put in a 100 mL volumetric flask for filtration. 30 mL of filtrate was drained, mixed with 30 mL of distilled water. And then the solution was extracted 45 mL for later use. Extraction was performed with 20 mL, 25 mL and 30 mL dichloromethane for 40 min, and the remaining raffinate was combined in each extraction. Then a rotary evaporation was used to evaporate and concentrate to 1 mL for standby.

2. Chromatographic column: Capillary column of db-wax (60 m × 0.35 mm × 0.25 μm). Column temperature: the initial temperature was 40°C for 2 min, followed by elevation by 5°C/min to a temperature of 60°C. Then the temperature increased to 100°C at a rate of 10°C/min, and rose to 240°C at a rate of 18°C /min for 6 min. The carrier gas was nitrogen, the split injection ratio was 1: 40, the injection volume was 1 μL, the temperature of the injection port was 220°C, and the temperature of the detector was 240°C.

Improvement of the key favour compounds by RSM

The influence of pre-treatment method (low temperature freezing, normal temperature preservation, high temperature boiling), fermentation temperature (50, 60, 70, 80 and 90°C), and fermentation humidity (30, 40, 50, 60 and 70%) on the 5-HMF formation was studied by single factor tests. On this basis, the Box-Behnken central combination design method was used to design a response surface experiment with 3 factors and 3 levels to optimize the fermentation process (Yang et al., 2020). The factors and levels were listed in Table 1.

Statistical analysis

The Box-Behnken central combination design method was performed, and the multiple fitting was conducted by using Design Expert 8.0 to establish a parametric regression model and analyse the fermentation process of fermented garlic.

Determination of flavour component and the establishment of quality evaluation system

The fermentation of fresh garlic to fermented garlic is mainly the results of enzymatic Browning and non-enzymatic Browning, among which the most important one is non-enzymatic Browning, namely Maillard reaction. In the reaction process, reducing sugars in fresh garlic interact with amino acids to produce carbonyl ammonia reaction, which produces melanoidins, darkens the garlic cloves of fermented garlic, and produces aroma (Nakagawa et al., 2020). In addition, sugars produce a certain amount of organic acids under the action of certain enzymes and microorganisms such as lactic acid bacteria in the fermented process. These metabolites produced in the process of biological transformation from the unique food sensory characteristics of fermented garlic products. The purpose of scientific production can be achieved through the data analysis of these metabolites and the monitoring of the production process. Through the accumulation of experience in production practice, it was determined that reducing sugars, acids, polyphenols, 5-HMF and water were the key quality components of fermented garlic. The source of reducing sugars in fermented garlic is the hydrolysis of starch in fresh garlic. As the substrate of Maillard reaction, reducing sugars directly affect the process of Maillard reaction in fermented garlic and determine the accumulation of melanoidins. At the same time, the high content of reducing sugar can mask the bitter, astringent and sour taste of fermented garlic, increase the sweet taste of the product, and improve the flavour of the product from many aspects. Acid substances are the main cause of the sour and sweet taste of fermented garlic and are generated by carbohydrate metabolism. However, if the total acid content is too high, the sour taste is too heavy and difficult to swallow. If the total acid content is too low, it cannot give fermented garlic sweet and sour flavour. Phenolic substances are an important component of fermented garlic. When fermented garlic is heated and fermented at high temperature, polyphenolic substances decompose into many small substances and release a large amount of phenolic hydroxyl, which indirectly increases the total phenol content, thus giving fermented garlic strong antioxidant ability. The content of phenolic substances directly affects the function and function of fermented garlic (Kim et al., 2012). 5-HMF is a heat-induced degradation substance, mainly derived from Maillard reaction and thermal decomposition of sugars. 5-HMF has antioxidant properties and beneficial effects, but excessive 5-HMF has some toxic effects, such as carcinogenesis, mutagenesis etc. So it must be controlled within a certain range. Studies have shown that the variation of 5-HMF content can be used as an important indicator to predict the blackening rate of garlic samples. And in the food industry, 5-HMF is also used as a standard indicator for determining food quality in the food industry (Zhang et al., 2015; Lee et al., 2020). In addition, 5-HMF has the function of flavour enhancement and colour blending. With the continuous reaction of 5-HMF, a lot of brown substances and aromatic substances will be produced, giving black garlic unique flavour (Zhang et al., 2012). And according to the research report, the furfural content in black garlic is the most significant (Molina-Calle et al., 2017). Therefore, it was considered as the key aroma component that can reflect the quality of black garlic. Water affects the taste and quality of black garlic. At the same time, as an important participant in biological transformation, it affects the production process. Through the data analysis of the content distribution of characteristic indexes in different grades of fermented garlic, it could be found that when the content of reducing sugar was higher than 40%, fermented garlic showed bright black brown with obvious clear sweet taste. When the reducing sugar content was between 34 and 40%, the skin of fermented garlic had a slight yellow colour and tastes sweet. When the content of reducing sugar was between 28 and 34%, the skin of fermented garlic was dark, brown and generally sweet, with slight astringency and bitterness. When the content of reducing sugar was lower than 28%, fermented garlic surface was mostly uneven yellowish brown, with poor sweetness and obvious bitterness. Therefore, in the fermentation process of fermented garlic, the content of reducing sugar should be increased as much as possible, which will give fermented garlic excellent taste and improve the quality of fermented garlic.

Acid substances are an important cause of fermented garlic's sweet and sour taste. After data analysis of its content distribution, it was found that when the total acid content was between 3.2 and 3.8%, fermented garlic was suitable for sweet and sour taste and has no peculiar smell. When the total acid content was between 2.5 and 3.2%, the sour taste of fermented garlic was not obvious and the taste was sweet. When the total acid content was between 3.8 and 4.4%, fermented garlic had obvious sour taste and sour taste. When the total acid content was lower than 3.2%, fermented garlic had no obvious sour taste and smells of garlic, while when it was higher than 4.4%, fermented garlic had too much sour taste and is difficult to eat.

Polyphenols impart antioxidant ability to fermented garlic and affect its function. Through the data analysis of the content distribution of total phenols in fermented garlic, it was found that when the content of total phenols was higher than 10 mg/g, fermented garlic had a good taste and a bright dark brown colour. When the total phenols content was between 8 and 10 mg/g, fermented garlic tasted good and had a slight yellow skin. When the total phenols content was between 6 and 8 mg/g, fermented garlic was brown with a slightly bitter taste. When the content of total phenol was lower than 6 mg/g, the colour of fermented garlic was uneven and the bitterness was obvious.

As a precursor of melanin-like substance, 5-HMF can reflect the Maillard reaction process. At the same time, as the key aroma component of fermented garlic, 5-HMF can give black garlic unique aroma, but too much 5-HMF will give fermented garlic a certain bitter taste and has some toxic effects, such as carcinogenesis, mutagenesis etc. Through the data analysis of the content distribution of 5-HMF in fermented garlic, it was found that when the content of 5-HMF was between 8 and 12 mg/g, the taste of fermented garlic was sweet and sour with obvious aroma and no bitterness. When the content of 5-HMF was between 12 and 15 mg/g, fermented garlic was suitable in taste with no bitterness, but the aroma was not obvious. When the content of 5-HMF ranged from 15 to 18 mg/g, fermented garlic had a sweet and sour taste and a bitter taste. When the content of 5-HMF was higher than 18 mg/g, fermented garlic had a sour and sweet taste but a severe bitter taste. While when the content is lower than 3 mg/g, the Maillard reaction is not sufficient and there is no sweet and sour taste.

Water is the key factor in the processing of black garlic. If the content is too high, it will be soft, rotten and sticky. If the content is too low, it will be dry and hard. Through the data analysis of the water content distribution of black garlic, it was found that when the water content was between 35 and 45%, the texture of black garlic was soft and non-sticky. When the water content is between 45 and 55%, the texture of black garlic is soft and slightly sticky. When the water content is between 25 and 35%, black garlic is hard in texture. When the moisture content is higher than 55%, the texture is soft and rotten, and the teeth are very sticky. When the water content is lower than 25%, the black garlic is very dry and hard.

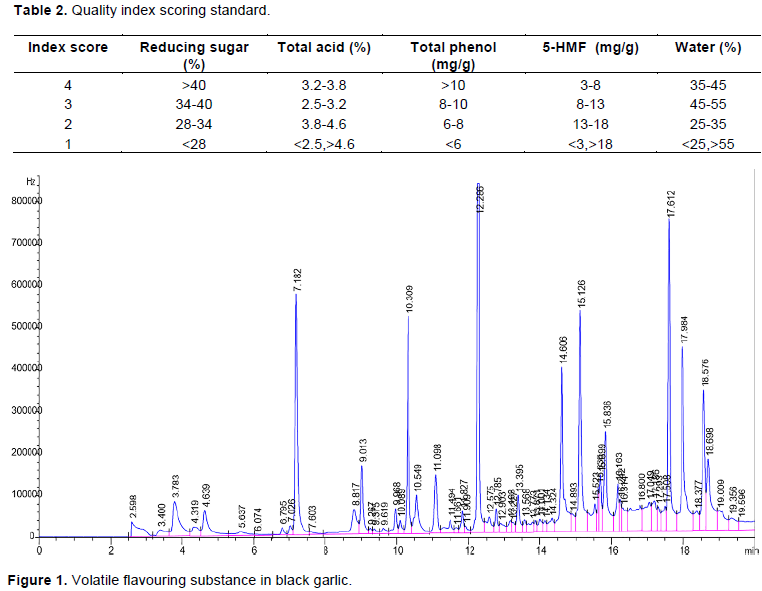

According to the above analysis, reducing sugars, total acid, total phenols, 5-HMF and water content could be divided into four scoring criteria (full score was 20 points). The specific results were shown in Table 2, which will provide theoretical reference for quality control and process optimization in future fermented garlic production.

After heat treatment in the fermentation process, the cell structure of garlic is destroyed, resulting in the release of alliinase. It leads to the degradation of sulphur compounds such as allicin, and the generation of thiophene, furan, furfural and other melanin-like substances, making fermented garlic has a unique flavour. The specific volatile flavour components in fermented garlic are shown in Figure 1, 15 volatile flavour compounds in black garlic were detected by GC , including acetone, 5 - methyl thiophene - 2 carboxylic methyl ester, 2,5-diethylthiophene, 4-methyl-4-hydroxy-pentanone, 5-methylfurfural, nonanal, furfural, ethyl acetate, 3,5,5-trimethylcycloethylene-2-enone, 4-benzoyl-2-hydropyran-3-one, 6-methyl-2-mercaptopyrimidine-1-oxide, 2-hydroxy-2 (p-methoxyphenyl) - 3-hydroxycarbonyl-3-methyl-butane, 2-acetylfuran, 3-methyl-2-carboxyamidothiophene, 1,3-dimethyl-1,3-dihydro-imidazol-2-thione.

It was found that diallyl disulphide and diallyl trisulphide were the main factors causing the pungent and spicy odour of garlic. They both had a pungent odour, in addition, diallyl trisulphide also had burning smell and sulphur smell. However, thioether compounds could not be detected in fermented garlic. This was because the unstable C-S bond of allyl-thioethers broke during the hot processing, resulting in propenyl radicals and alkyl-sulphide groups. Some of free radicals were converted into aromatic thiacycloalkanes during the heating process, while others reacted with low molecular compounds to form dipropenyl sulphide (Molina-Calle et al., 2017). The decrease of diallyl disulphide content significantly reduced the pungent odour and greatly improved the flavour of mature fermented garlic. In addition, pyrazines and alkyl-sulphides that were not present in fresh garlic have been found in fermented garlic. As a kind of aromatic substances, pyrazine is generated by the Maillard reaction of non-sulphur amino acids and fructose during the fermentation of garlic, which had a roasted aroma, and had an important contribution to the aroma performance of fermented garlic (Li et al., 2005).

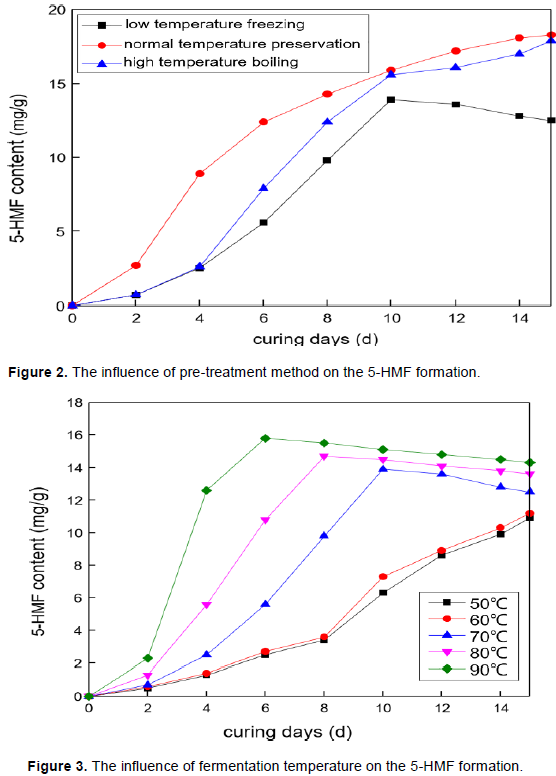

Effect of pre-treatment methods on the 5-HMF formation

As shown in Figure 2, in order to improve the flavour of fermented garlic and explore the influence of pre-treatment method on the 5-HMF formation, it was found that the final 5-HMF content in fermented garlic was significantly different under three different pre-treatment methods. By comparison, it could be found that the content of 5-HMF pre-treated by low-temperature freezing and high temperature boiling was lower than that stored at normal temperature, and the effect of low-temperature freezing was the most obvious, with a reduction of 5.4 mg/g. In the early stage of fermentation, the formation of 5-HMF was relatively slow in the high temperature boiling and low-temperature freezing treatment, which delayed the formation time and speed of 5-HMF. In addition, the content of 5-HMF could be reduced in the later stage of low-temperature freezing, which could reduce the bitterness brought by too much 5-HMF and improve the flavour of fermented garlic.

Effect of fermentation temperature on the 5-HMF formation

Fermentation temperature was also an important factor affecting the flavour formation of fermented garlic. As shown in Figure 3, after exploring the influence of different fermentation temperatures on the generation of 5-HMF, it could be found that when the fermentation temperature was 50 and 60°C, 5-HMF was always on the rise, and the final content was 10.5 and 10.9 mg/g, respectively. When the fermentation temperature was higher than 60°C, the content of 5-HMF increased first and then decreased. And with the increase of temperature, the less time it took to reach the maximum value, the higher the maximum value was. The higher temperature in the early stage of fermentation, the more sufficient the Maillard reaction and the more beneficial to the accumulation of 5-HMF. The lower temperature in the later period, the faster the consumption of 5-HMF, the more conducive to the preservation of the flavour of fermented garlic. Therefore, the temperature range needed to be controlled reasonably, 60, 70 and 80°C were selected as the ranges of response surface.

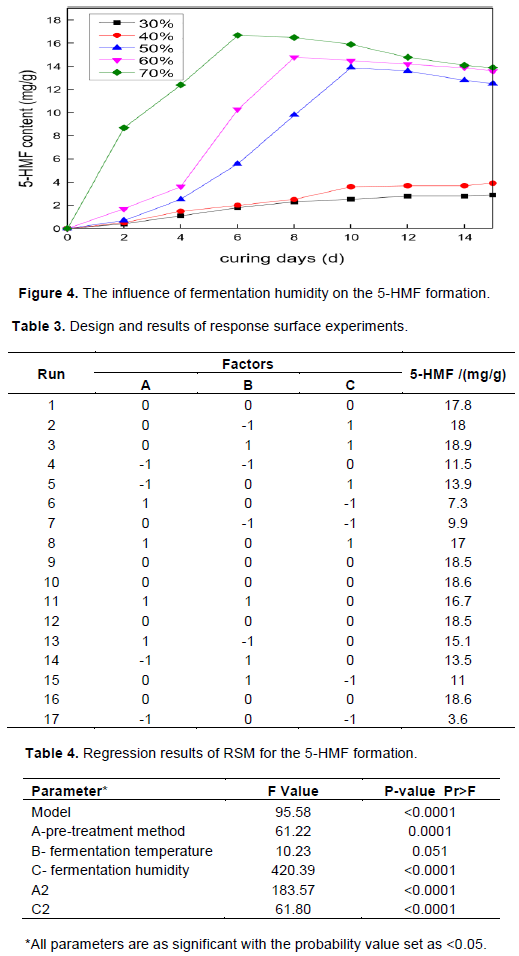

Effect of fermentation humidity on the 5-HMF formation

In addition to the two factors mentioned previously, fermentation humidity was also the key condition to enhance the flavour of black garlic. By exploring the effect of fermentation humidity on the 5-HMF formation, it was found that when the fermentation humidity was too low, the content of 5-HMF in fermented garlic is always on the rise, and the increase was not obvious. When the fermentation humidity was too high, the content of 5-HMF increased first and then decreased. With the increase of humidity, the time to reach the maximum value was less and the maximum value was higher. If the fermentation humidity was too low, the texture of fermented garlic was relatively dry and hard, and the tissue cells were in a compact state, so it was not easy to carry out Maillard reaction. Therefore, the production of 5-HMF in the early stage of fermentation was relatively small, and the amount of 5-HMF used to synthesize melanin after fermentation was also relatively small, so the content of 5-HMF showed a small increase. High fermentation humidity and soft texture of fermented garlic were conducive to the release of reducing sugar and amino acids for Maillard reaction, and the content of 5-HMF in the early fermentation period was greatly increased. Due to the improvement of the reaction environment, the amount of 5-HMF used in the late fermentation to produce melanin-like compounds was also relatively large, so the content of 5-HMF decreased slightly. As can be seen from Figure 4, high humidity fermentation in the early stage of fermentation could promote the generation of 5-HMF, providing a good preparation for the accumulation of melanoidins. Low humidity fermentation in late fermentation could inhibit the formation of 5-HMF, reduce the content of 5-HMF, reduce the bitter taste of black garlic, and contribute to the formation of good flavour of fermented garlic. Therefore, it was necessary to control the humidity range reasonably, 40, 50 and 60% were selected as the value range of the response surface.

Optimization of the fermentation process for the 5-HMF formation using RSM

Response surface analysis was used to optimize the fermentation process of black garlic, and the Design Expert 8.0 software was used to design a 3-factor 3-level experiment. The experiment scheme and the response results are shown in Table 3.

The Design Expert 8.0 software was used to perform multivariate fitting on the experimental data in Table 3, and regression analysis was carried out on its response value. On the basis of the regression analysis, the parametric regression model was established. The regression equation of the model for the 5-HMF formation was as follows:

Y = 18.40 - 1.00A + 1.71B + 4.49C - 0.01AB - 0.18AC - 0.050BC - 4.09A2 - 0.11B2 - 3.84C2

The variance analysis of the regression model of fermentation parameters of fermented garlic are shown in Table 4. In order to verify the reliability of the parameter regression models, the variance analysis was carried out for the regression equation. The results are shown in Table 4: the model was highly significant (P < 0.01), and the look of fit value was insignificant (P > 0.05), indicating that the regression model had good fitting effect and the experiment scheme was operable. R2=0.9919 indicated that the model was highly reliable and could be used to predict and characterize the response value of 5-HMF. R2adj = 0.9815 indicated that the fitting degree of the regression equation was very good. C. V. refers to the coefficient of variation of the equation, whose value was inversely proportional to the accuracy of the experiment. The larger the C.V. value was, the more unreliable the experimental result was, the worse the fitting effect of the equation was. C.V. % = 4.23 in the regression equation was within the acceptable range, so the experimental result had considerable accuracy. Therefore, the parameter regression model could be used to analyse the fermentation process of fermented garlic, and predict the 5-HMF formation.

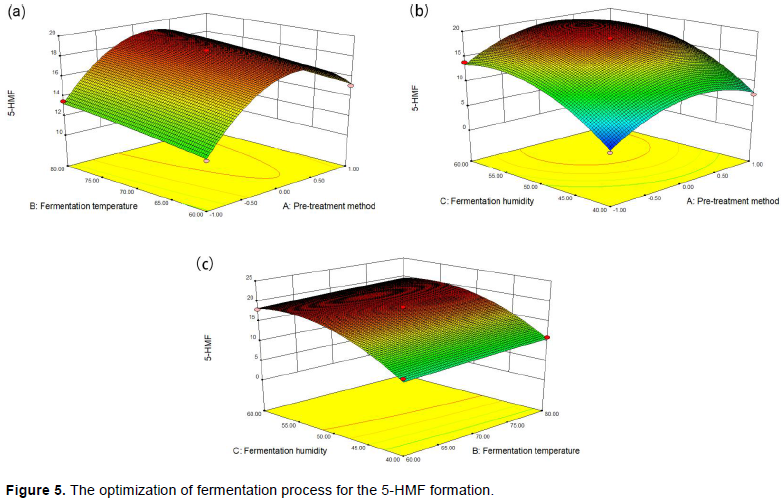

Based on the analysis of flavour substances of black garlic, the effects of pre-treatment method, fermentation temperature and fermentation humidity on the 5-HMF formation were studied. Then the response surface experiment was carried out to optimize the fermentation process. Figure 5 shows the influence of the interaction among factors on the generation of 5-HMF. The results showed that the main factor affecting the quality of black garlic was the fermentation humidity, followed by the pre-treatment method. As shown in Figure 5b and c, the content of 5-HMF decreases with the reduction of fermentation humidity, and the decline trend is very steep. This may be because the dehydration reaction of the precursor of 5-HMF is inhibited under high humidity. In addition, the formation of 5-HMF can be inhibited by low-temperature freezing and high temperature boiling in Figure 5a and b. It can be seen from Figure 5a and c that compare with the influence of humidity and pre-treatment method on the formation of 5-HMF, the content of 5-HMF does not change significantly with the increase of temperature. In order to further determine the factor level combination of fermentation process of black garlic, the optimal fermentation conditions were manufactured by Response Surface Analysis that the pre-treatment method was low temperature freezing, fermentation temperature was 61.8°C, and fermentation humidity was 40.2%. The response predicted from the model was 3.6 mg/g. Repeated experiments were performed to verify the predicted optimum. The results from the means of three replications (the content of 5-HMF was 3.7 mg/g) were mainly coincident with the predicted value and the model was proven to be adequate. Meanwhile, the quality of black garlic produced under optimal conditions was determined with a high quality score of 19.